I had the chance to talk with … Prashant Jagtap, CEO of Trayak, about designing products for sustainability. Prashant is a veteran of the PLM industry, and he and I had a great discussion about how design for sustainability fits into PLM. This post will share a bit of that discussion as well as a bit about Trayak.

Why is PLM the Place for Sustainable Design?

First, I want to share some of my discussion with Prashant on a general basis. I am a  big proponent of getting compliance and sustainability right during product design. Why? Because like so many other product attributes, sustainability is really hard to accomplish once the design is locked in. Material choices and manufacturing process decisions clearly have a significant influence on the environmental impact of a product. They are also very difficult to change after a product has bee designed because late product changes often sub-optimize a lot of previous design decisions which can increase cost, degrade product performance, or at a minimum cause a lot of disruption through engineering changes (ECOs).

big proponent of getting compliance and sustainability right during product design. Why? Because like so many other product attributes, sustainability is really hard to accomplish once the design is locked in. Material choices and manufacturing process decisions clearly have a significant influence on the environmental impact of a product. They are also very difficult to change after a product has bee designed because late product changes often sub-optimize a lot of previous design decisions which can increase cost, degrade product performance, or at a minimum cause a lot of disruption through engineering changes (ECOs).

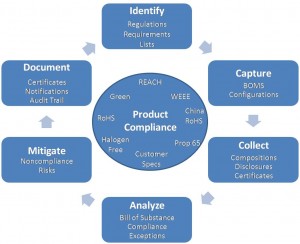

So earlier is better. But why in PLM? Simply put, PLM is where the product data is. PLM has the bill of material (BOM) early in the product lifecycle. As PLM has matured it has extended to capture the manufacturing processes in a bill of process (BOP) as well. That is the right core of information required to conduct an effective lifecycle analysis (LCA). As the Tech-Clarity compliance/sustainability diagram above shows, making the right decisions requires a combination of product information and impact data. To me, this is an obvious extension of PLM. In fact, environmental compliance and sustainability is the example I use most frequently when I discuss the four dimensions of PLM expansion.

What does Trayak Do?

So other than sharing some common philosophy about how  manufacturers can design more sustainable products, Prashant was excited to tell me about the progress Trayak is making. Their goal is to “make sustainable product design mainstream.” The idea is to put the right tools and information into engineers’ hands (or at least their desktops) so they can understand the environmental impact of their design decisions. Trayak believes that the current LCA tools are too complex, too expensive, require experts, and are too separated from the design process. I believe changing that could have a profound effect. Engineers would love to make more eco-friendly products, but face a myriad of tradeoffs and typically don’t have the right information at hand. How can you optimize what you don’t understand? How can you design for sustainability when you don’t know the impact of your decisions until after the fact? To me, solving those problems is the value Trayak has to offer.

manufacturers can design more sustainable products, Prashant was excited to tell me about the progress Trayak is making. Their goal is to “make sustainable product design mainstream.” The idea is to put the right tools and information into engineers’ hands (or at least their desktops) so they can understand the environmental impact of their design decisions. Trayak believes that the current LCA tools are too complex, too expensive, require experts, and are too separated from the design process. I believe changing that could have a profound effect. Engineers would love to make more eco-friendly products, but face a myriad of tradeoffs and typically don’t have the right information at hand. How can you optimize what you don’t understand? How can you design for sustainability when you don’t know the impact of your decisions until after the fact? To me, solving those problems is the value Trayak has to offer.

What do they Offer?

Trayak offers three products:

- EcoDesigner – helping engineers design for compliance using LCA techniques

- EcoLabel – a tool to help grade BOMs and provide labeling information for compliance (for EPEAT regulations)

- EcoScore – a broader solution that collects a wide range of factors/criteria about environmental impact (which could include LCA results) which could also be used to create scoring mechanisms to rate their product portfolio as they evaluate greener design options

Who do they Work with?

Here, to me, are two valuable facts about Trayak:

- They understand CAD and PLM, and have integrated into Siemens PLM tools (including Teamcenter and Solid Edge) – Prashant’s history and experience play a big role here

- They are LCA agnostic – Trayak does not believe that there is one right way to do LCA. In fact, they believe that some companies may already have a source of LCA information. Trayak is partnering with EcoInvent for data, but is built with the expectation that they will work with multiple sources of information. A very interesting approach. As more OEMs start to demand LCA information, what are the chances that suppliers will have to support more than one set of LCA calculations? Pretty good, I bet.

So that’s what I hear from Trayak, I hope you found it useful. What do you think? What else should I have asked them? Do you think the open approach to LCA will make a difference?