A quick peek into some research on … how product portfolio management (PPM) can be more closely tied to engineering projects.  The research, Issue in Focus: Product Portfolio Management in a PLM Strategy – Closing the Loop on Product Planning explores the connection between PLM and PPM for manufacturers that focus on intense engineering programs as opposed to high-volume products like consumer packaged goods (CPG). I look forward to your thoughts as I shake off the cobwebs from a summer that involved too little attention to blogging. But it was a good summer, and I hope you enjoyed yours (or your winter for those of you in the Southern Hemisphere).

The research, Issue in Focus: Product Portfolio Management in a PLM Strategy – Closing the Loop on Product Planning explores the connection between PLM and PPM for manufacturers that focus on intense engineering programs as opposed to high-volume products like consumer packaged goods (CPG). I look forward to your thoughts as I shake off the cobwebs from a summer that involved too little attention to blogging. But it was a good summer, and I hope you enjoyed yours (or your winter for those of you in the Southern Hemisphere).

The Research Findings

Most of the research I have read – and written– on PPM in the past has focused primarily on fast-moving consumer goods. Clearly, consumer goods companies live and die based on a steady stream of new and innovative products with extremely short product lifecycles. But what about companies that focus on engineering-centric products like aircraft? Or organizations like Sandia Labs, interviewed for the paper, a multi-program engineering and science laboratory? Don’t they have to manage and balance their engineering investments? Do they have any special needs?

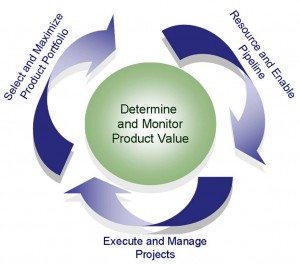

The research starts by reporting that the basics of PPM still apply, companies need to focus on the following four fundamentals:

- Select and Maximize Product Portfolio

- Resource and Enable Pipeline

- Execute and Manage Projects

- Determine and Monitor Product Value

Beyond that, the research points out that PPM processes are often disconnected from other product development and engineering processes. The paper then asks the question “What additional value can be achieved through a tighter integration between PPM and PLM, and from closing the gap between product planning and the reality of the underlying design and development efforts?” In fast-moving consumer goods, the R&D project is complete before production begins. The die has been cast from a portfolio perspective by the time the product is released. In more engineering-intense industries, however, program management is ongoing during the entire project and real knowledge can replace early assumptions. This is where the opportunity lies to close the loop between the engineering program and the portfolio, so portfolio assumptions can be monitored and updated as the engineering proceeds. This is also true for fast-moving goods during the R&D process, of course.

Implications for Manufacturers

So why is this important? PLM have grown, as discussed in my Four Dimensions of PLM Expansion. Many PLM initiatives now include portfolio management in their scope. Further, PLM vendors including Siemens PLM, PTC, Dassault Systemes, and others have added PPM to their product suites. Enterprise vendors SAP and Oracle also have PPM offerings in addition to PLM. Does this present an opportunity for tighter integration? The paper does more good at bringing up the question than answering it. The most important advice in the research is “…manufacturers shouldn’t integrate because they can, they should find the right areas of value to focus in across the four core PPM processes.” I believe the integration opportunities will vary by company, but the good news is that the door has now been opened and the potential is there.

So that was a quick peek into some recent research on portfolio management, I hope you found it interesting. Does the research reflect your experiences? Do you see it differently? Let us know what it looks like from your perspective.

Please feel free to review more free research and white papers about PLM and other enterprise software for manufacturers from Tech-Clarity.