I always look forward to briefings with the CoLab Software team. That’s partially because I think they’re doing something interesting and because I’m following a trend toward systems of engagementto see where it goes. It’s also because they have a dynamic team that is passionate about what they’re doing and has good perspectives to share on the industry.

The Basics

Here are some of the basics to the set the context from our recent briefing. You can also read our short writeup from last year if you’re interested. CoLab is a seven-year-old company, they are VC funded, and they are growing nicely. According to a press release from Insight Partners in May, CoLab has grown revenue nearly 10x in the last two years. We’ve been impressed that they are working with some very large companies including Ford, Komatsu, Polaris, Johnson Controls, and Schaeffler as well as government institutions.

The System of Engagement Trend

The System of Engagement Trend

CoLab delivers a system of engagement (SOE) primarily focused on the tangible challenges engineering teams face with design review. I’m going to step back and talk about systems of engagement, feel free to skip ahead if you are on board. SOEs are becoming more popular as a way to differentiate a style of application and user experience that are typically more lightweight and agile than existing systems of record (SOR) that manage data. SOEs are filling an important systems ecosystem gap by enabling collaboration across one or more SORs such as PLM, ERP, or others.

The system of engagement concept is important given the fragmented nature of today’s systems, for example the variety of systems that contain a part of the product digital thread. Our research, in fact, shows that most manufacturers have more than one PLM system. The idea is to integrate across these systems to deliver processes / workflows that enable collaboration and allow people to take action based on contextual data about their current. It’s what I called “the potential second half of the PLM promise” in a previous post, if for no other reason because it acts beyond a single system.

As an aside, I’m starting to think of the need to differentiate “Industrial” SOEs that are based on the product / manufacturing data context, the digital thread, as opposed to general SOE platform without any industry specialization. But that’s for another time. I realize this is a lot to digest but I think the background is important and I tried to keep it short and simple.

CoLab’s Design Engagement System

CoLab offers a very specialized SOE focused on design and engineering, the design engagement system (DES). In particular, they have drilled in very specifically on solving the inefficiencies manufacturers face with design review. This is an example of a company really focusing and going deep to solve a challenging problem. CoLab gives engineering teams the ability to share designs so others can review and leave detailed, contextual feedback on them. For example someone in manufacturing could add a comment or markup to a specific feature in a specific version of a CAD model. Their review provides contextual feedback to the design team so they can analyze and act on it. But differently than most third party collaboration or viewing tools, that feedback persists over time and stays associated with that particular revision. In this way, design review feedback is not a lost moment in time, it becomes a part of the product history and company knowledge.

There are other solutions that support design review, including those from PLM vendors themselves. But CoLab is going deep and creating an experience tailored specifically to the design review process. They have really focused on the user experience to make it efficient and effective, going so far as to make it “self-documenting” to prevent additional non-value-added work to capture feedback.

Their portals are a great example of how tailored their solution is. CoLab creates a workspace for the internal team and then allows them to create multiple, linked portals to securely share designs selectively with suppliers to gather feedback. What’s really interesting about the portals is that each one is not just a separate disconnected copy. Suppliers can’t see other’s feedback, but the design team can see consolidated feedback from all of the additional portals in their internal workspace. To me, this is a great example of building a tailored solution works in the real world instead of an idealized environment.

The Secret Sauce

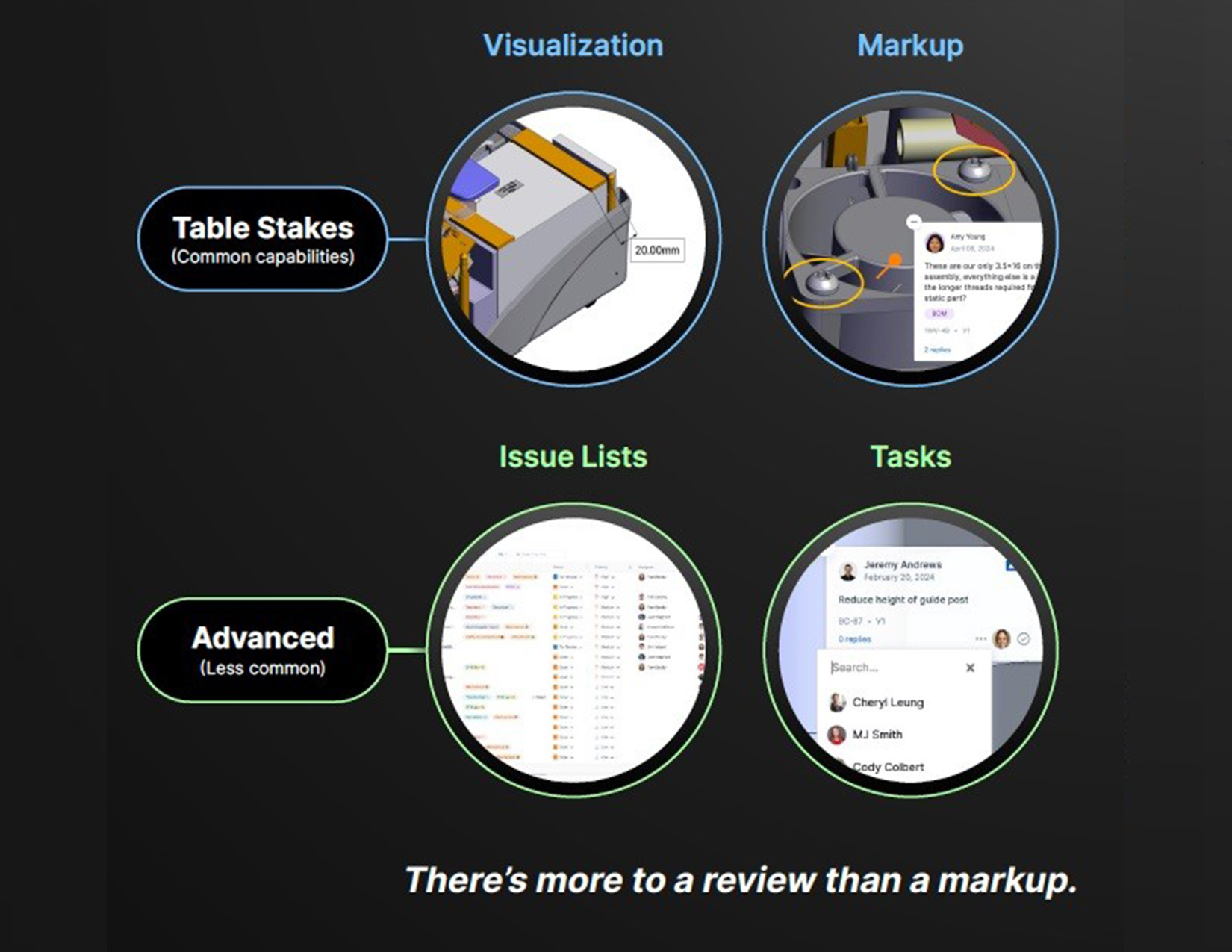

Part of what makes CoLab effective is what they call “replacing the messy middle” between existing CAD, Project Management, and PLM systems. This is a big factor in allowing them to help design teams move away from informal, ad-hoc (and ineffective) tools like spreadsheets that are far too common in these processes. One of the key ways to support this effectively is by providing the reviewer the right context, the underlying CAD model for example, so they can act effectively. I like the way CoLab calls this “cutting down on the context gap” as they manage the relationships between visualization, markup, issue lists, and the tasks engineers and others are executing.

Looking Forward

CoLab’s system of engagement, or even more specifically their design engagement system, will not stop at design review. The collaborative capabilities are already being applied to help manufacturers with design review, supplier collaboration, and cost reduction programs. But they have lots of room to grow and some exciting plans for the future.

One example that caught my attention is that they have meaningful plans to incorporate AI. Everyone is talking about AI, but I believe CoLab is on to something important. If you think about the design review feedback they capture as company knowledge, the potential value of mining and learning from that information to improve future design review, or design in the first place, is intriguing. There will be more to come on that, we are following it closely.

Final Thoughts

CoLab is taking their DES / SOE role seriously. They are happy to sit outside of PLM and not get directly involved in managing CAD data. Instead, they access it from PLM and supply it in an accessible form to design review participants. They are partnering with PTC and have integrated with Windchill, a PTC Technology, and they are working toward other PLM systems including Siemens Teamcenter and Dassault Systèmes 3DEXPERIENCE platform. They will integrate beyond PLM as well.

We’re still watching to see how the system of engagement model as a separate platform plays out. You can clearly make an argument that a design execution system should be part of a broader product innovation platform. But CoLab is filling an important gap, and it’s becoming increasingly clear that there will not be one home to the product digital thread inside the enterprise let alone in the supply chain where design review must excel.

Thank you Adam Keating and MJ Smith for the update!