How Vertex Overcomes Common Collaboration Challenges

Vertex can do more than just support collaboration by sharing 3D data, but it’s a great example so let’s start there. There are some key challenges manufacturers face when sharing data. Vertex has some clever approaches to address these.

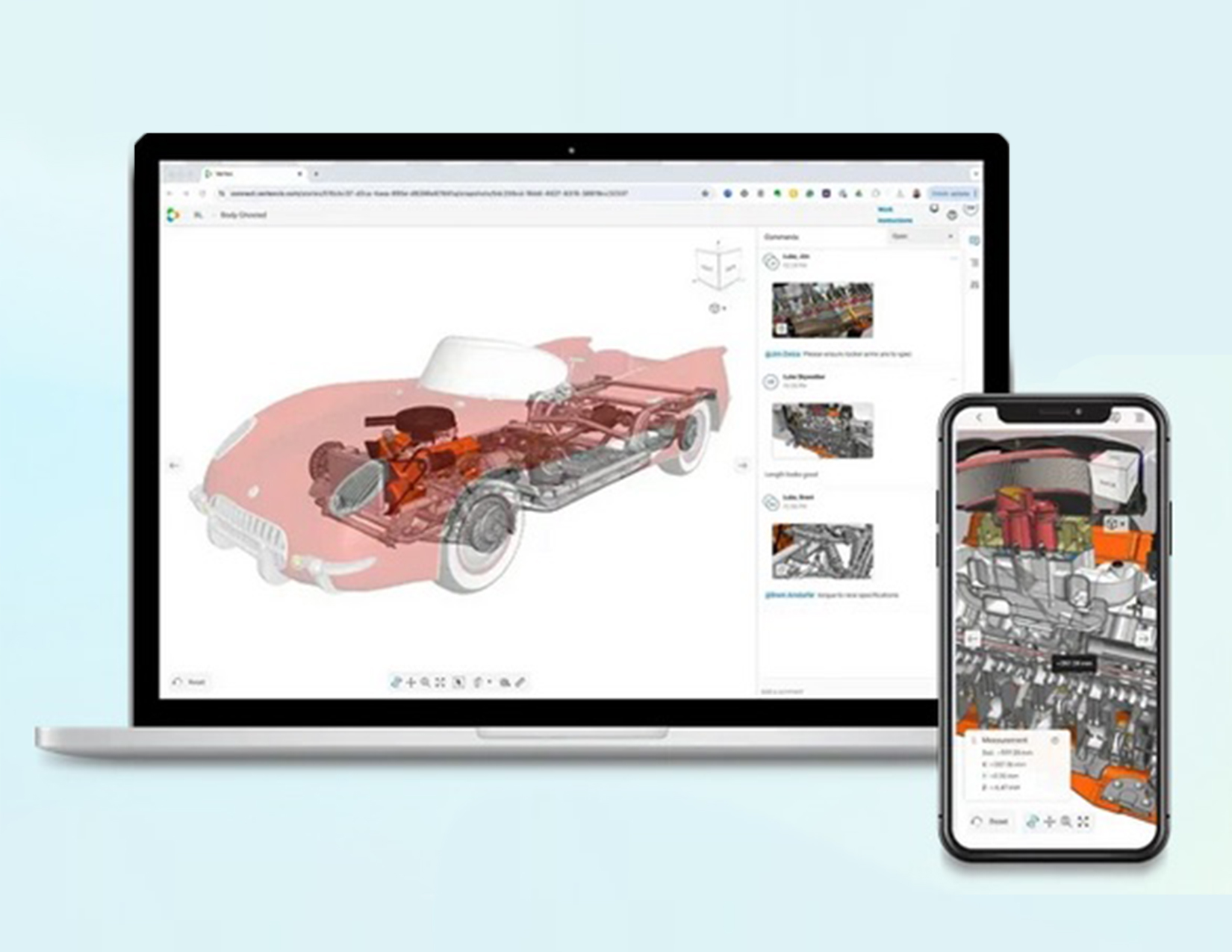

- Accessibility – Downstream departments typically don’t have access to 3D CAD software. The same is true for many others who value 3D data at their suppliers and customers. Vertex delivers an interactive 3D viewer that is accessed with through the cloud with no installation necessary. It provides support across any device by using web components and their patented context-aware pixel streaming.

- Compatibility – Manufacturers commonly struggle to share 3D data from engineering and suppliers with others due to compatibility issues caused by data stored in a variety of CAD Formats. Vertex interprets 3D and stores it securely in the cloud. It can combine data from multiple CAD formats into its data model. It’s also important to share that it can also bring in and combine data from other systems like ERP.

- Context – Sharing 3D is a challenge, but sharing manufacturing-oriented 3D data is more challenging because it must understand and respect the complex relationships between the data. Vertex’s solution shares associative, context-aware pixels based on BOM data and associated CAD metadata.

- Performance – 3D CAD data is commonly very complex and is stored in very large file sizes. Companies typically have to share partial data or reduce data fidelity to share this kind of data, particularly for complex, discrete manufacturing assemblies. Vertex’s approach supports high-fidelity scalability by streaming pixels instead of sharing files.

- Security – Finally, companies are rightfully concerned about sharing 3D product data because it contains highly valuable intellectual property (IP). Vertex’s streaming approach also means no files are shared, and no data is stored on the client as they view data.

Beyond Collaboration

We don’t have enough time to dive into all of the ways that streaming contextual 3D can drive value for manufacturers, but here are a few to consider that go beyond simple data sharing:

- Digital twins

- Model-based definition (MBD) and semantic PMI

- Shop floor applications

- Product support and field service

- Customer and distributor-facing applications like parts catalogs

- Request for quotations (RFQ)

Vertex’s platform provides an open capability to support use cases like these and more. It provides a data model and database that can ingest 3D CAD data so manufacturers can build apps to serve it to the right people in the right context.

Final Thoughts

We were impressed with the large OEM customers they work with, including John Deere, Atlas Copco, and Caterpillar, and believe they are an important player to watch in this space. We’re excited to follow their development and see how broadly Vertex will be adopted. Thank you to Vertex Software for reaching out and to Brent Arndorfer and Chris McMillan for sharing their company’s strategy and capabilities.