A quick peek into some research on … how the roles of ERP and PLM have evolved from Tech-Clarity’s most recent report, Tech-Clarity Insight: The Evolving Roles of ERP and PLM – Integrating the Roles of Execution and Innovation. This research is a follow up to The Complementary Roles of ERP and PLM.  The paper furthers my previous research and describes how the use of these enterprise systems has evolved, and the associated maturation of the integration between ERP and PLM systems. As my past research has concluded, these systems remain the cornerstone of product profitability and are better together.

The paper furthers my previous research and describes how the use of these enterprise systems has evolved, and the associated maturation of the integration between ERP and PLM systems. As my past research has concluded, these systems remain the cornerstone of product profitability and are better together.

The Research

The research included interviews with manufacturers Emerson and Cameron, along with an interview with a Systems Integrator that focuses on ERP-PLM integration. What I appreciated the most about the integrator’s perspective is that they partner with leading vendors of both PLM and ERP software, and understand both perspectives. Having worked closely with ERP systems prior to reconnecting with my engineering roots and focusing more on PLM, I recognize how rare it is to speak with people that really understand (and respect) both domains.

The Research Findings

At the highest level, the key takeaways from the research are:

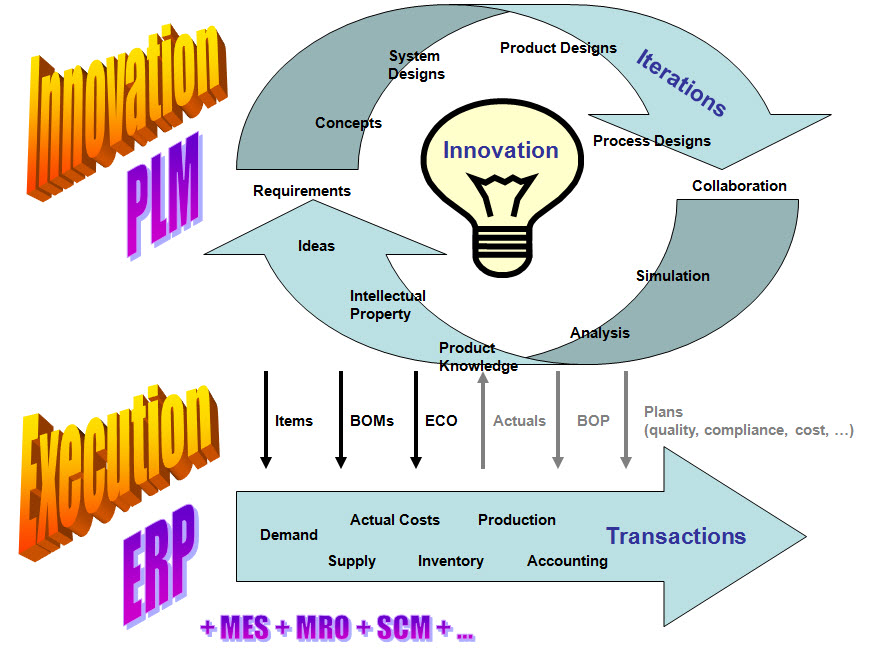

- PLM and ERP still play distinct, complementary roles in helping manufacturers drive product profitability

- ERP supports the business of planning and managing the execution cycle

- PLM owns the innovation cycle – including product development and engineering

- Companies are making great progress in integrating ERP and PLM, as ERP-PLM integration has become the norm and many have moved to advanced levels of integration

What Else is New?

The advances in integration caused me to rework my “Innovation Cycle – Execution Cycle” framework that I use to explain the roles of ERP and PLM. I have changes the model to reflect a more bi-directional model, and to support exchanges of more advanced information including:

- Bill of Process (BOP) – including the ERP “routing” in addition to the manufacturing BOM

- Quality, Compliance, and Cost plans – from PLM to ERP for execution

- Actual results – from ERP to PLM, including costs, inventory levels, etc.

The other thing that is new is not well reflected in the graphic yet. That is that ERP is frequently managing the execution of the manufacturing business, but not necessarily executing it. There is frequently a layer of solutions including Manufacturing Execution Systems (MES), MRO, Supply Chain Management, and others that manage real-time execution and integrate to ERP as the backbone. But that is a study for a different time.

Implications for Manufacturers

So what can manufacturers learn from this research? The first thing is that they shouldn’t be spending their time choosing between ERP and PLM. They need both. The second is that integration has moved from a “nice to have” to a standard, and that more advanced companies are extending ERP-PLM integration beyond release to manufacturing and change management. Companies that haven’t integrated the ERP and PLM systems are now behind the competitive curve. Of course if your company doesn’t have both ERP and PLM, your business is either very unique or the chances are you are even farther behind the curve. The good news is that it appears easier to integrate ERP and PLM than ever before due to advances in technology, and that companies are improving efficiency and reducing cost by doing so. So the task at hand is easier to achieve, and provides solid payback. Sounds like ERP and PLM integration needs to be on everybody’s enterprise systems agenda.

So that was a quick peek into some recent research on the roles of ERP and PLM, I hope you found it interesting. Does the research reflect your experiences? Do you see it differently? Let us know what it looks like from your perspective.

Please feel free to review more free research and white papers about PLM and other enterprise software for manufacturers from Tech-Clarity.