A quick peek into some research on … product compliance for formula-based companies in a report titled Issue in Focus: Product Compliance – The Hidden Tax on Innovation: Enhancing Innovation in Formula-Based Companies through Real-time, Automated Compliance Monitoring.  One of the predictions that came true in Mythbusing Product Innovation and PLM 2010 Predictions was that PLM would expand to address product compliance. My past reports, such as the report on Making Product Compliance Sustainable, focused primarily on regulations like RoHS and REACH that impact product people that make discrete items like electronic or mechanical devices. But formula- and recipe-based product developers face their own set of compliance challenges. This report focused on their needs, and how PLM systems can help reduce the manual workload burden placed on them by product compliance.

One of the predictions that came true in Mythbusing Product Innovation and PLM 2010 Predictions was that PLM would expand to address product compliance. My past reports, such as the report on Making Product Compliance Sustainable, focused primarily on regulations like RoHS and REACH that impact product people that make discrete items like electronic or mechanical devices. But formula- and recipe-based product developers face their own set of compliance challenges. This report focused on their needs, and how PLM systems can help reduce the manual workload burden placed on them by product compliance.

The Research Findings

The research included interviews with consumer goods companies including Revlon, Zotos International (a division of Shiseido Co,. Ltd.) and made a few key observations:

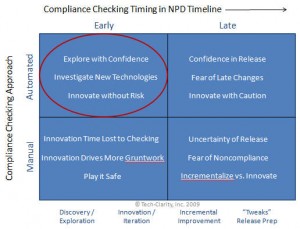

- Early compliance checking helps avoid rework and speed time to market in product formulation and testing by ensuring product contents are acceptable early in the product development process

- Manual product compliance processes are slow, inneficient, and inhibits innovation by forcing key innovators to spend inordinate amounts of time looking up information and making it difficult for them to try new, innovative ideas quickly and with confidence

Given the need for early compliance checking and the potential for these checks to grind product innovation to a halt, companies appear to be between a rock and a hard place. The report goes on to discuss how real-time, automated compliance monitoring can help relieve the innovator of this compliance burden so they can focus on developing great products. This requires an infrastructure that:

- Provides knowledge of global compliance requirements

- Recognizes the full composition of their raw materials

- Understands the product formula as it is being designed

- Checks compliance real-time as the developer innovates

- Provides full, electronic documentation of compliance

There is more detail on each of these requirements in the report.

Implications for (Formula-Based) Manufacturers

For companies that develop and manufacture formula-based products, the compliance challenge will only grow. Government regulations and consumer sentiment will continue to push companies with greater scrutiny of their product contents, and restricted material lists will continue to grow. On the other hand, consumers will continue to reward innovate new products. In order to meet both demands, product developers must have the right tools to innovate rapidly, but with the comfort that there is a system behind them that will keep them out of compliance trouble.

So that was a quick peek into some recent research on making product compliance more efficient for product developrs in formula-based industries, I hope you found it interesting. Does the research reflect your experiences? Do you see it differently? Let us know what it looks like from your perspective. Please feel free to review more free research and white papers about PLM and other enterprise software for manufacturers from Tech-Clarity.