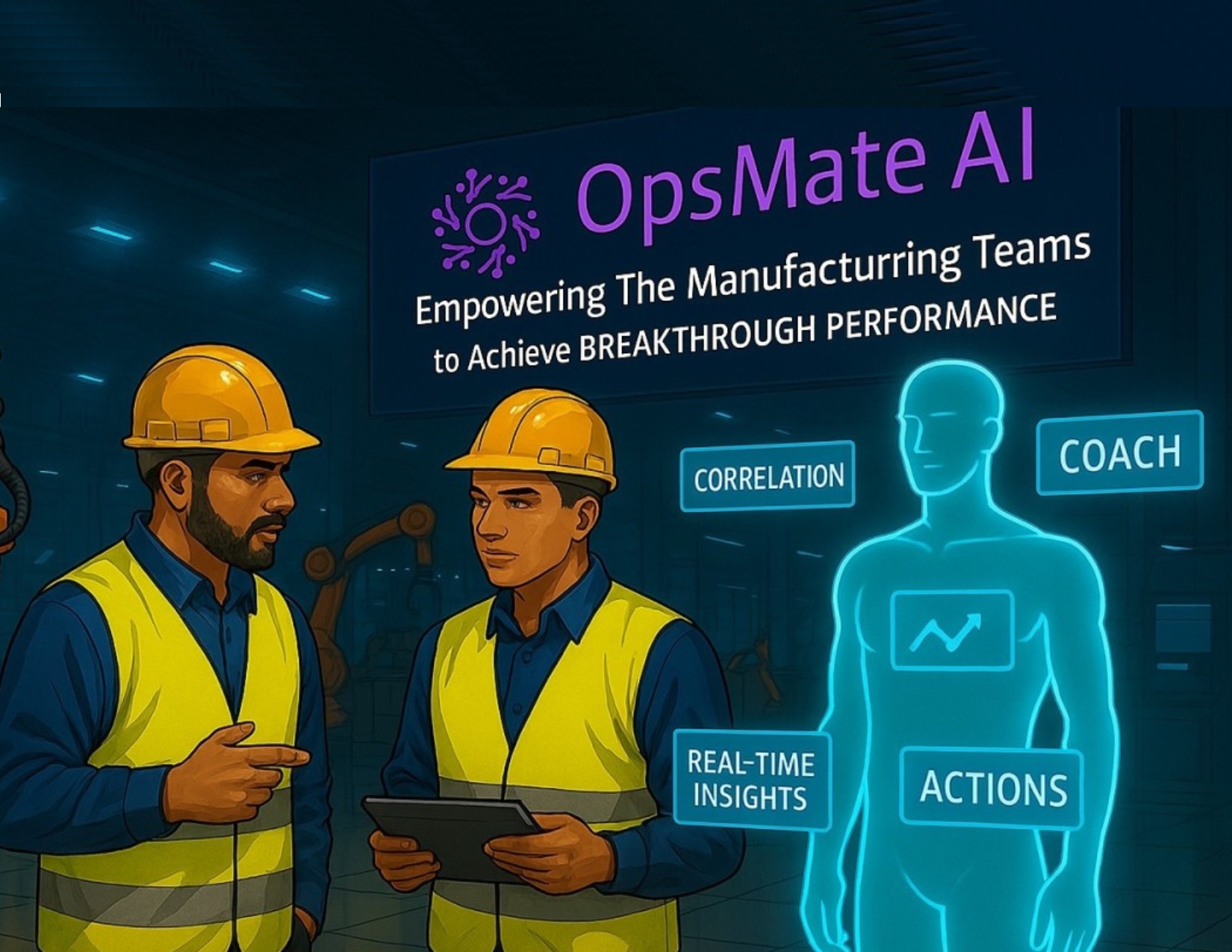

Can agentic AI improve how people work on the factory floor? Can it address the workforce crisis that has resulted in a plateau in productivity and increasing safety incidents? OpsMate AI believes they can do that quickly with their no-code agentic AI platform, which is purpose-built for the complexity and high-stakes environment of manufacturing operations. Their approach is to use generative and agentic AI to create hyper-intelligent digital teammates that assist the factory workforce.

Flexible Knowledge Assistants

Flexible Knowledge Assistants

Agents have access to more information than a person could. The agent-as-assistant concept makes sense, particularly in the unpredictable world of day-to-day operations. No matter the level of skill or experience an operator or associate has, they can ask the agent and get not only data but information, knowledge, and reasoning. This is quite different from traditional hard-coded, pre-defined applications and dashboards.

The great news about genAI is that it can train on a wide variety of data. So, it can naturally bridge the IT/OT divide. Whether the data is from IoT, MES, a machine, SharePoint, or a Teams transcript, OpsMate AI can ingest it, bring it together, put it in context, and make it available in any language.

High-Value Use Cases

As with all genAI, these agents work with natural language queries, not through coding or formal queries. They can answer questions, guide work, perform analysis, or take on routine tasks. This early-stage company created an advisory board based on the founders’ deep existing manufacturing relationships.

This advisory board has pointed to the common use cases that they would find valuable in their workflows. Since then, the OpsMate AI team has been busy building their minimum viable product to address those needs. Some of the initial use cases involve acting as a virtual technician to support less experienced maintenance staff with what is otherwise tribal knowledge. Another use case seeks to replicate the EH&S expertise of front-line managers with agents mentoring the workers.

Layers of Knowledge

OpsMate AI points to 3 layers of knowledge: general, industry-specific, and customer-proprietary knowledge. OpsMate AI builds in the first two, but the customer keeps control of their own data. They get an instance and decide who has access to address security and privacy concerns. The customer-specific knowledge repository can come from existing documents (SOPs, manuals, checklists, drawings, troubleshooting logs, corrective action reports, etc.) Experts can also train the model through an interview and knowledge capture process where their expertise becomes encoded in agents.

Once the agent is trained on the appropriate knowledge collection, it can effectively perform its tasks. The digital workforce will be available for in-line, real-time guidance for anyone in the plant. It could be as simple as “What does this PLC error code mean?” or as complex as “How can I maximize yield?” The system will also be transparent in showing the source(s) of data that lead to its recommendations.

Autonomous Digital Workforce

OpsMate AI founders have developed a roadmap to an autonomous digital workforce, augmenting the people who remain at the center. They see robots doing physical work and OpsMate AI agents doing knowledge work. Over time, the agents can learn more and. progress from being virtual experts to analyzing data to executing tasks. At some point, they may fully automate tasks and become autonomous.

Possible Rapid Benefits

We see the possibility of this being a breakthrough for customers. Our research shows that GenAI can deliver significant benefits quickly. Systems that have been purpose-built as agents for factory floor issues, such as what OpsMate AI offers, are attractive because they have so much pre-built. Manufacturers seeking to shore up aspects of the operation that most need additional knowledge and expertise should take note.

Early Stage Progress

OpsMate AI has a strong base of advisory board manufacturers driving its initial product development. These companies have their data in it and are testing and helping refine it. We expect to see a commercial release around the middle of this year.

Thank you, Howard Heppelmann and James Zhang, for briefing us on your vision and early customer direction. We appreciate the pragmatic approach to agentic AI for production.