Can you shorten the time to value (T2V) for MES? In a recent briefing, Julie Fraser came to an understanding that Infor is working to do that with its no-code configuration approach. Infor MES comes from a heritage of encouraging customers to use the solution completely out of the box with no custom code. It may sound far-fetched, but they claim customers are doing that.

Can you shorten the time to value (T2V) for MES? In a recent briefing, Julie Fraser came to an understanding that Infor is working to do that with its no-code configuration approach. Infor MES comes from a heritage of encouraging customers to use the solution completely out of the box with no custom code. It may sound far-fetched, but they claim customers are doing that.

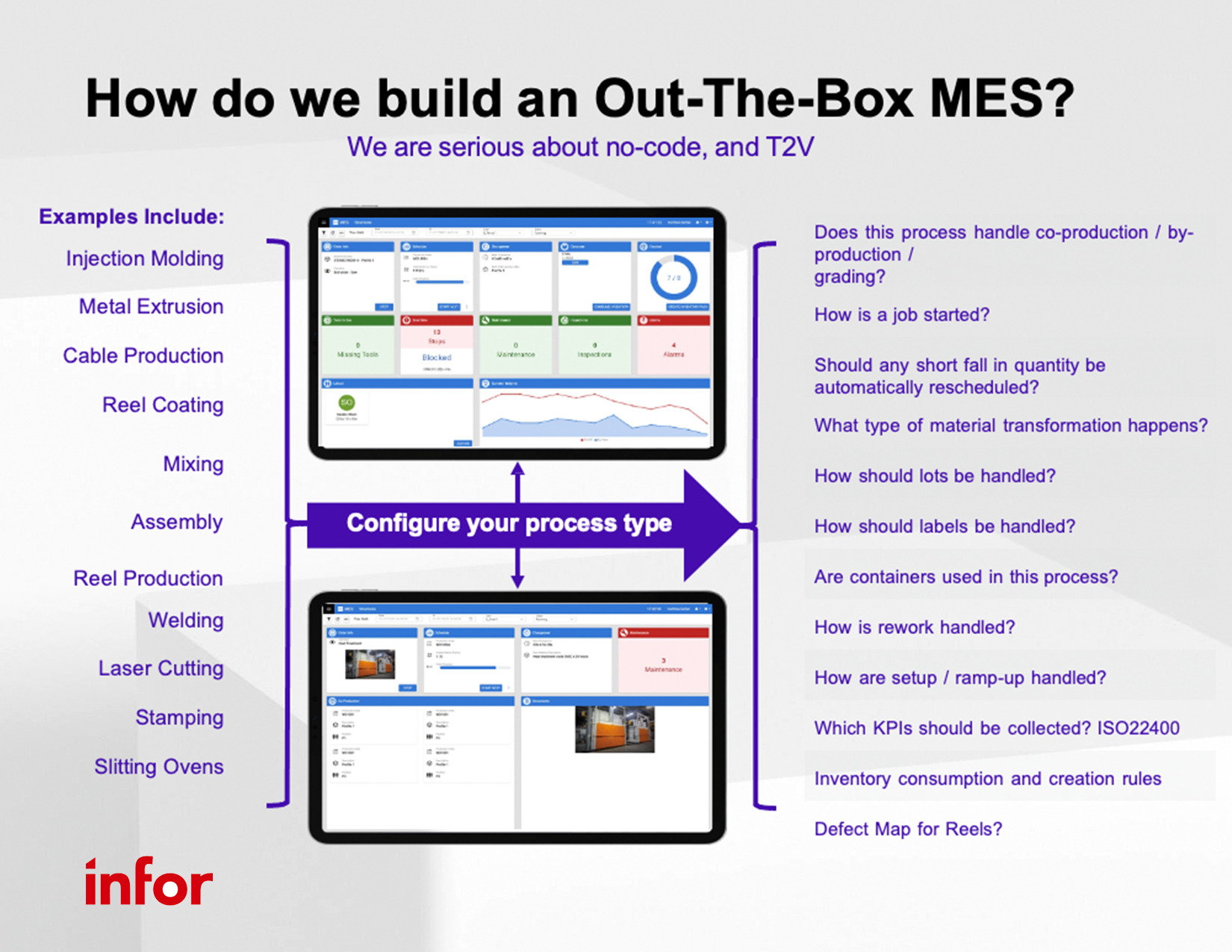

Infor MES’s approach is different, with many examples of “last mile” functionality plus built-in options that the manufacturer can select, rather than create. Newer examples of special functions using no-code include reel production including defect tracking and co-production variations for ovens, stamping, grading, reel slitting, and painting. Integrations and connections are also largely based on field- and expression-based mappings.

Infor’s MES covers all factory operations for a relatively wide variety of industries and production modes. Broad areas include production, quality, inventory, logistics, maintenance, tooling, and energy. This enables their ERP products to focus on their core functions and strengths, removing complexity from ERP and allowing MES to simplify operations.

The all-organically developed MES also supports frontline workers with a consistent look, feel, and view of everything in their production environment. The operator’s dashboard is built from pre-defined or user-configured “cards” with saved reports behind each. These reports can be combined for valuable views for each process, area, and role in the facility. Screens are built simply, knowing gloves and goggles are common for these users.

MES is integrated to many of the Infor ERP CloudSuites, but not tightly coupled. Standalone MES sales are still a substantial portion of the base. Yet, more complete integration is also boosting cross-selling to existing Infor ERP customers. Investment continues in Infor MES to solve more customer challenges.

MES is a differentiator for the Infor ERP suites. The ability to leverage the Infor OS Platform, which includes data lake, data fabric, robotic process automation, and Generative AI is a huge boost to the enterprise’s ability to make full use of MES data.

Infor MES is available with a choice of hosting options:

- Traditional on-premises.

- Enterprise – single tenant for global master data across multiple factories.

- Distributed Enterprise – central hosting of master data and reporting, but individual factory or regional instances for reliability, redundancy, and low latency.

Infor’s twice-a-year spring and fall product release cycle works for MES. The roadmap includes more configurability, extended mobility, and making the most of Infor innovations. The next release is scheduled to include integrations with Infor Document Management and new GenAI functionalities, for example.

Sometimes, a robust small software company’s acquisition by a much larger company works well for customers and employees. That appears to be the case with Infor’s MES, which was Lighthouse Systems (Shopfloor-Online) until late 2021. Infor has taken this product seriously. The company sees Infor MES adding substantial value to customers looking to achieve complete digital transformation of manufacturing operations.

Thank you, Jennifer Marzolf for arranging this briefing with MES mavens Matt Barber and Brandon Billingham. We look forward to following the MES and other Infor products’ developments and successes in the market.