What’s one of the most challenging aspects of manufacturing digital transformation? Getting fast access to the right current production information in a usable format. MFGx has set about solving that problem over the past several years by developing Fuuz and is about to raise its profile as it expands beyond its consulting and ERP partners to sell through VARs and direct.

Julie Fraser is excited about the Fuuz by MFGx MES Platform after a briefing with MFGx founder Craig Scott and new EVP of Sales Steve Modrall, a long-time industry sales pro. Here are a few of her key takeaways from the conversation.

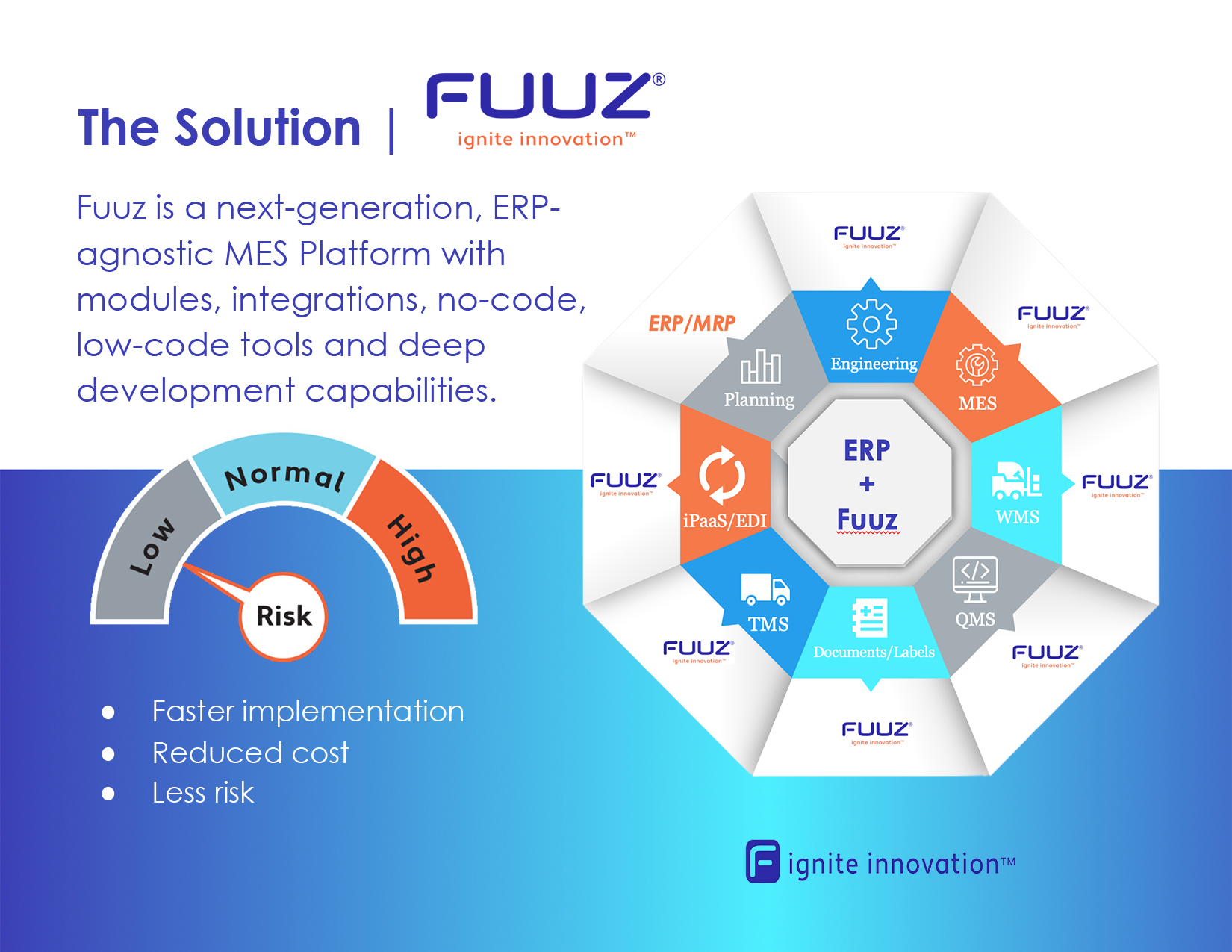

Fuuz is the manufacturing plant floor software partner of choice for Oracle NetSuite and the preferred MES for other major ERP vendors. The software originated to enable digital transformation for manufacturers beyond what a single ERP can offer. The event-driven platform and no-code, low-code toolset enable ERP to send and receive meaningful information – not just data – throughout the company. Customers can build, tailor, or apply what they need more specifically, too.

The Fuuz MES Platform is both an integration platform as a service (iPaaS) and a platform as a service (PaaS) purpose-built for manufacturing. OK, that’s a lot to process.

- iPaaS: It’s got the infrastructure to support digital thread for complex manufacturers. Integration in the form of out-of-the-box pre-built connectors is improved with self-healing, auto-correcting technology in the platform to keep those integrations updated as things change.

- PaaS: It has the capability for manufacturers to develop what they need that’s specific in functions, data tables, fields, and user interfaces.

In our interpretation, MFGx delivers a Unified Namespace (UNS)* in a single platform rather than a stack of different products. The MFGx team reports the Fuuz MES Platform can store, contextualize, and serve out the data rapidly enough for plant floor dashboards to have sub-second performance despite cloud hosting.

In our interpretation, MFGx delivers a Unified Namespace (UNS)* in a single platform rather than a stack of different products. The MFGx team reports the Fuuz MES Platform can store, contextualize, and serve out the data rapidly enough for plant floor dashboards to have sub-second performance despite cloud hosting.

Fuuz also includes functional modules in addition to the platform. Examples are manufacturing execution (MES), preventative maintenance, warehousing (WMS), and quality (QMS). Any of these may be the easy entry point to fill a gap in a manufacturer’s functional landscape.

Given the nature of the platform, customers can adjust these modules to enhance their fit. Fuuz has not only no-code, low-code development options but also pro-code or full software development in traditional programming languages. According to MFGx, customers and partners develop applications 7-10X faster with Fuuz than other products on the market, with fewer limitations.

The platform is delivered with continuous deployment, so all customers are always up-to-date. Fuuz is on a multi-tenant cloud, true SaaS environment (with edge available). Customers get a log-on and annual contract with pricing options such as unlimited user subscriptions that invite scale-out.

To us, that means manufacturing customers on Fuuz SaaS do not have to adjust anything on the cloud infrastructure. IT can focus on what matters most to its operations customers and simultaneously have a streamlined tech stack.

The Detroit-area company has customers in automotive, food and beverage, medical devices, chemicals, plastics, rubber, A&D, retail, and distribution. Our takeaway is that the infrastructure must work securely to enable regulated industries to validate the software.

Over the past couple of years, the services partner network for Fuuz has grown to include PwC, MHI Solutions, Logical Systems Inc. (LSI), and Razorleaf, with others in process. With service partners to deploy and ERP partners to sell, the MFGx team has been free to focus on developing their software.

With this history, the company has not had a high profile in the market. That may be about to change. The company is starting to focus on both recruiting VARs and selling directly to enterprise accounts. Their ecosystem of ERP and service partners speaks well of Fuuz’s capabilities, as does its growing customer base of over 100 companies and over 1000 sites.

Thank you, Craig Scott and Steve Modrall, for taking the time to brief us. Thank you, Kathy Suchowiecki, for setting it all up for us. We look forward to following Fuuz’s growth and its partners and customers in the market.

*Unified Namespace (UNS), as coined by Walker Reynolds, is the hub in an event-driven architecture where all data to run the business lives. This data is both IT and OT, no matter what layer in the ISA95 model, enterprise, plant, line, equipment, or IoT. All systems publish into UNS and pull from it as needed.