The market for MES in mid-sized manufacturers has traditionally been underserved. Major MES vendors find it unsuitable, as it conflicts with their direct sales model and complex product offerings. However, mid-sized manufacturers have the same MES needs as larger companies but lack the IT resources necessary to implement and support these systems.

The market for MES in mid-sized manufacturers has traditionally been underserved. Major MES vendors find it unsuitable, as it conflicts with their direct sales model and complex product offerings. However, mid-sized manufacturers have the same MES needs as larger companies but lack the IT resources necessary to implement and support these systems.

Decades of Service to Discrete Manufacturers

ISE has provided MES and paperless shop floor solutions for forty years through its MV2 MES solution. It has been proven to excel at understanding and addressing the needs of mid-market discrete manufacturers. The combination of customer satisfaction, recommendations, and ISE’s longevity suggests it’s delivering to customer needs. Topping the list of differentiators is ease of use, which was evident in its demonstration.

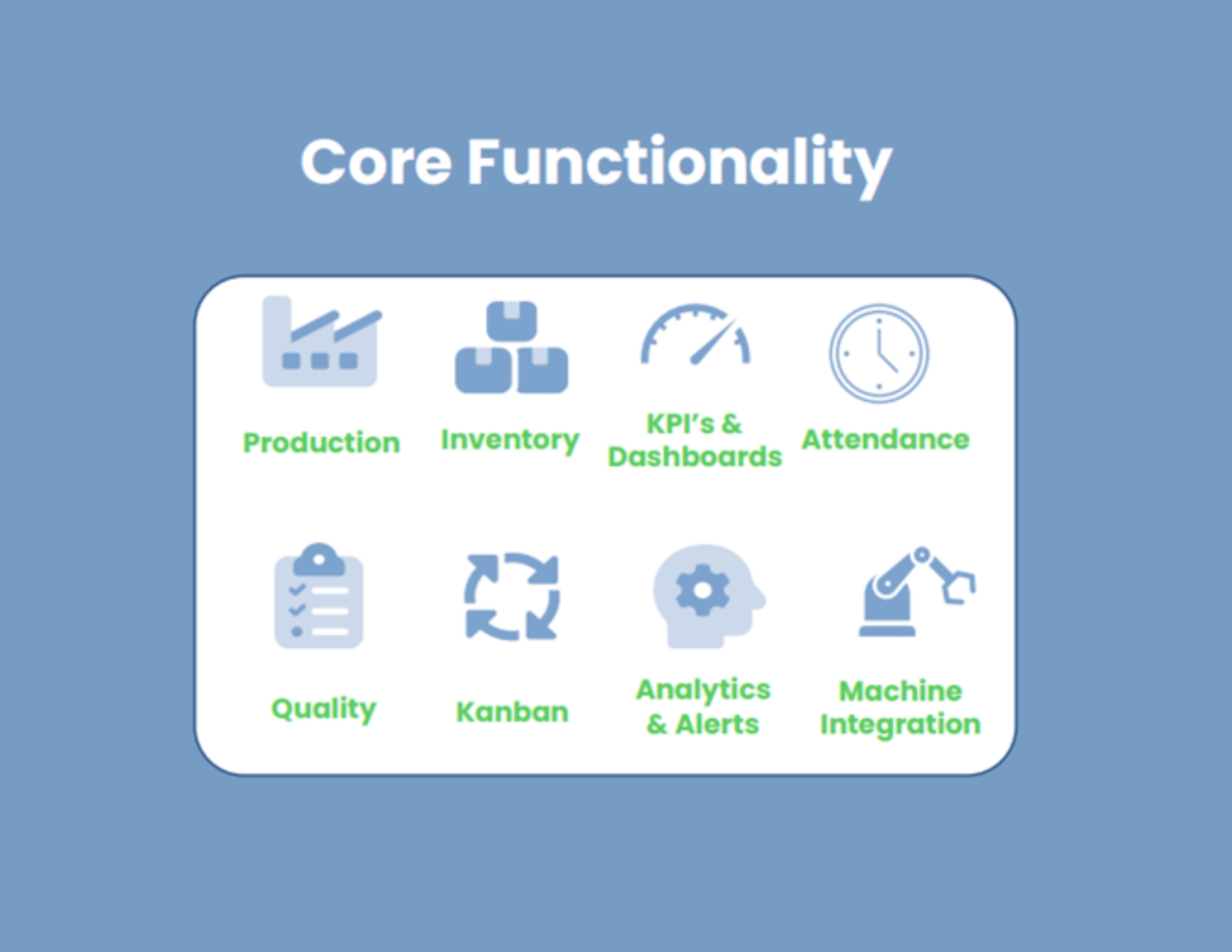

Broad-based Standard Functionality

The MV2 product’s broad-based standard functionality encompasses essential MES features, including production scheduling and execution, quality management, inventory control, time and attendance, Kanban, machine integration, and real-time analytics. These tools are specifically designed to meet the needs of mid-sized discrete manufacturers, ensuring cost-effective implementation and operational efficiency. Its MV2 platform is positioned as a flexible and scalable solution for a diverse range of discrete manufacturing environments, with a breadth of functionality that matches and, in some cases, exceeds that of enterprise-scale MES solutions.

Expanded ERP Support

ISE has been providing solutions to discrete manufacturing industries, with a focus on the unique challenges faced by mid-sized manufacturers in this market. The company was established to complement and integrate with what is now the Infor XA ERP system. More recently, ISE added standard ERP integration to Microsoft Dynamics 365 Business Central. Through its open architecture and API integration toolkit, MV2 has been integrated with other ERP systems such as SAP and Epicor Kinetic.

Focused on Results

I had the pleasure of attending ISE’s Manufacturing Optimization Forum event on September 25, 2025. The event included a panel session featuring four customers who shared their experiences and the benefits they realized from MV2. Some highlights I heard include:

- Simplicity & User Adoption: Customers highlighted how MV2’s straightforward interface allows users to quickly learn the solution and adopt it in their production facilities. They also reported that it is easily tailored to fit business needs without requiring someone with strong IT skills.

- Cultural transformation: Customers said that MV2 is fostering a mindset of continuous improvement and empowering their shop floor teams to drive change.

- Efficiency gains: There were reports of a significant reduction in manual data entry with MV2, helping to enable proactive management. One customer reportedly eliminated 20 hours a week spent manually keying in data.

- Inventory Accuracy: One customer went from 70% data accuracy to averaging 90% accuracy over the past two years. Another touted the elimination of their annual physical inventory by achieving 95% daily accuracy on their cycle counts with MV2.

- Data-driven decisions: Customers reported increased accuracy in quoting, pricing, and labor cost analysis due to accurate production data in MV2.

Looking Forward

The evolution of MV2 is centered around three main pillars: scalability, interoperability, and user-centric design. Scalability ensures the MV2 product can grow alongside its customers’ operations, accommodating increasing complexity without compromising performance. Interoperability focuses on seamless integration with other enterprise software systems, ensuring adaptability to different technological ecosystems. Ultimately, the user-centric approach prioritizes intuitive interfaces and streamlined processes, enabling manufacturers to optimize efficiency with minimal training and support requirements. Together, these pillars form the foundation for ISE’s vision of delivering its comprehensive MV2 MES solution tailored to the distinct needs of smaller manufacturers.

Thanks to Jay Gentle, Erin Bonde, Chris McLean, Dan Van Kempen, Jim Rozewicz, and Rick Reith at ISE for catching us up on the latest news.