Can MES be available for manufacturers of all sizes, with reasonable pricing, the ability to connect to automation, fast implementation, and credible operations IT know-how behind it? Kanoa is aiming to achieve that goal by building MES modules on top of Inductive Automation’s Ignition platform. Kanoa is building MES in a low-/no-code platform that is easy to customize and connect based on the Ignition foundation.

Growing into MES

Kanoa started about six years ago as a system integrator partner for Ignition but has recently moved into the Alliance Partner program. That caught our attention and matches the company’s focus on developing and selling software. So far, Kanoa has developed two multi-function MES modules: Ops and Quality. Each solution comes with the Kanoa MES database, Kanoa MES modules for Ignition, and the Kanoa APP Ignition project.

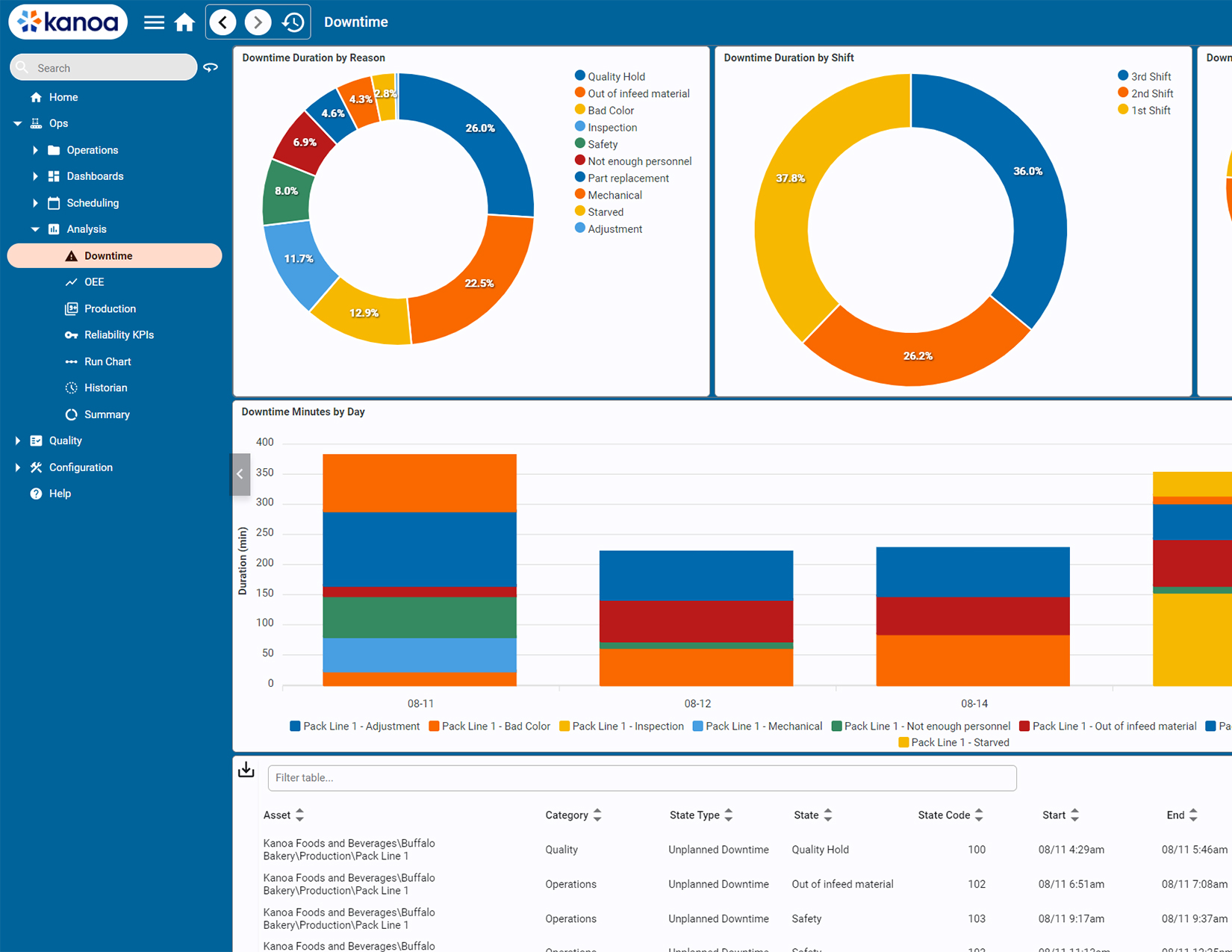

In the Ops module, they claim to deliver OEE with just three pieces of data: in-feed, out-feed, and state. Work orders, shift schedules, etc., are in the application. Kanoa Quality is a paper-to-glass solution for digitizing manufacturing forms, dispatching forms to operations teams, and analyzing quality data through SPC analysis.

MES needs vary by industry. Kanoa has OEE and quality solutions today. Other MES functions, such as track and trace, are still in development. As the modules grow, the database enables streamlined data processing and management across modules. The core delivers security and governance features. Often, manufacturers who are unable to find what they want in other MES solutions come to Kanoa as a simplified alternative to get started.

Ignition to Start

Many Kanoa customers are Ignition shops seeking to expand into MES; they find a significant shortcut in Kanoa. Ignition was built as an IT and SCADA platform for industry and has been widely adopted by manufacturers and system integrators. Kanoa has had success in the established Ignition customer base but has also sold Kanoa along with Ignition to companies that were not already using it.

The Ignition platform lets Kanoa easily integrate into automated processes and equipment. Manufacturers who have their machine data can set up Kanoa to leverage it in minutes. Naturally, change management and adoption take longer. Yet, with the ability to create your own apps and screens as well as tweak what Kanoa offers out of the box, it may be faster than many MES projects. Kanoa also has a simple user interface for manual data entry that requires minimal training.

Customer Fit

Kanoa’s commercial efforts focus on small and medium businesses. The price point fits smaller company budgets, with Ignition starting with Basic at less than $15K, Kanoa Ops at $20K, and Quality at $25K. However, the company is also implementing multi-site MES for larger organizations, some with dozens of plants involved worldwide.

Unlike many MES, Kanoa is designed to fit many industries. So far, it has had strong traction in food and beverage, plastics extrusion, and building materials. However, its functionality is not adequate for regulated life sciences industries or those needing batch management.

Thanks, Sam Russem, for taking the time to explain Kanoa’s approach and offerings to us. We look forward to more conversations and watching as Kanoa progresses in the market.