Can multi-tenant cloud-based low-code software run and optimize production operations? Apparently, some companies are using TilliT for just that. The combination of MES with quality, AI-powered scheduling, analytics, and edge technology serves not just mid-market but also smaller and larger companies. Partners and manufacturers are deploying the system themselves after just a few days of training.

Can multi-tenant cloud-based low-code software run and optimize production operations? Apparently, some companies are using TilliT for just that. The combination of MES with quality, AI-powered scheduling, analytics, and edge technology serves not just mid-market but also smaller and larger companies. Partners and manufacturers are deploying the system themselves after just a few days of training.

With the June announcement of Australia-based TilliT being acquired by Nordics-based Roima Intelligence, we expect more manufacturers will start to consider this system. Roima has a broad global presence and is growing rapidly, raising its profile for both software and services. TilliT adds digital execution and production scheduling that can deliver value quickly.

MES, Quality, APS, CWP, Analytics

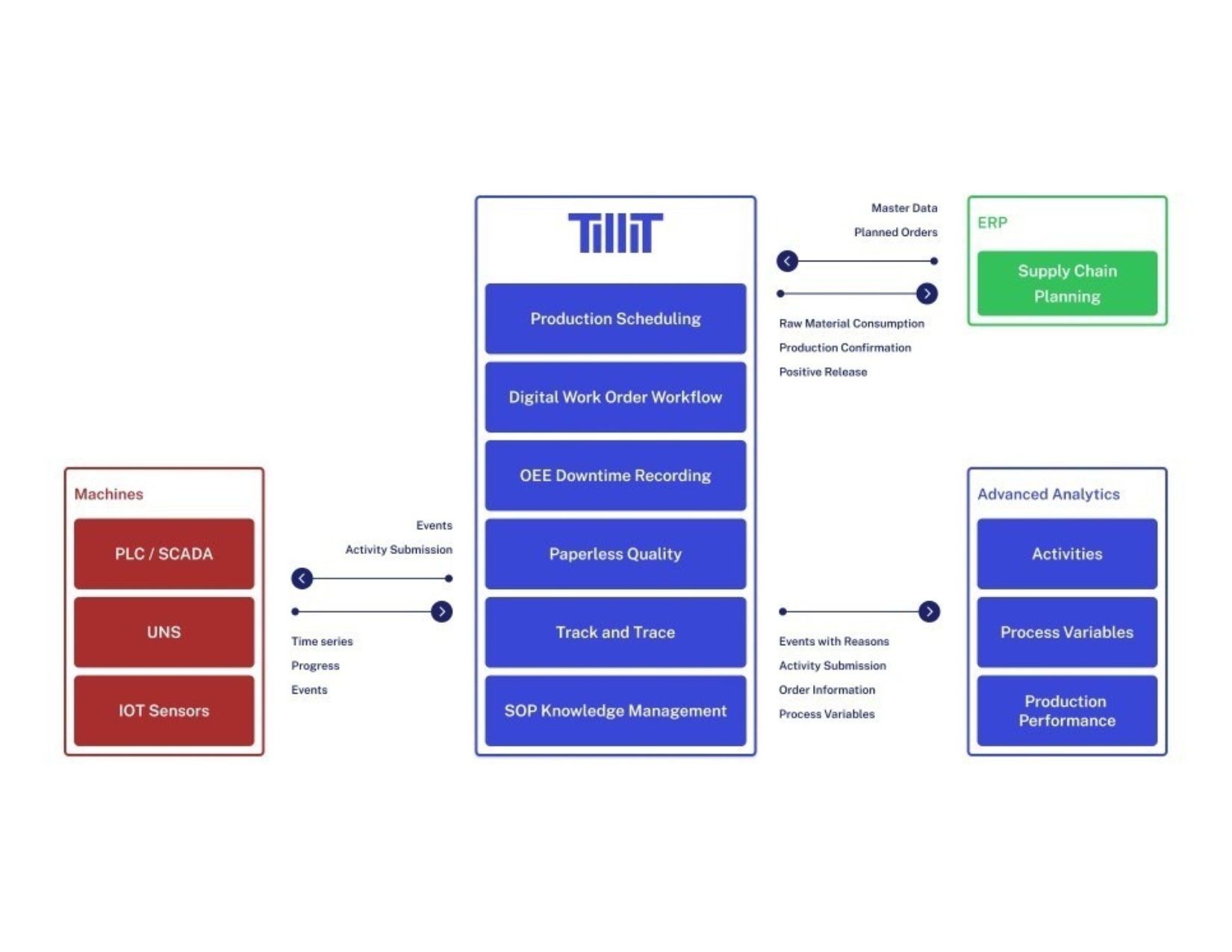

TilliT’s functions include production scheduling, workflow for digital work orders, OEE and downtime recording, paperless quality, track and trace, a mini data historian, and knowledge management, including SOPs. In addition to these capabilities, it includes analytics for activities, process variables, and production performance.

- Quality or auditing is a common entry point into TilliT, leveraging its workflow capabilities.

- Scheduling is designed for multi-step batch or discrete manufacturing operations, but not complex assembly.

- Operators use an action panel that lists tasks and instructions for performing them. The panel can also open forms to ensure process adherence. If something goes wrong, the system can order a root cause analysis.

- Supervisors approve activity as needed.

- A mini data historian is also built-in to show analog trended historized data from sensors and equipment.

The system is designed to orchestrate machines, people, processes, and materials, flowing seamlessly among the functions an operator, engineer, or supervisor needs to perform. While we list functional areas, they do not appear separate to the user.

TilliT was already a merger of two companies, one with MES or digital execution modules and another with AI-based production scheduling. Each of these is still available independently, but is integrated natively. Naturally, the systems also have integration with automation and equipment as well as ERP and SCP.

Event-Driven, Cloud-Based, Low-Code

TilliT is event-driven and based on the concepts of assets, orders, and activities, which the system models and manages in workflows. In these workflows, the project team can work bottom-up to specify automated sets of activities and triggers where and when human interactions are needed. They can also specify expiration times for activities and escalation methods. Using events, triggers, and rules is typically an easy way to record tribal knowledge and create an accurate model of production.

Part of the magic of TilliT is that it is no- / low-code. It needs no customization. Low-code configuration of assets, materials, and attributes is with a proprietary manufacturing-specific form builder. TilliT uses drag-and-drop, not coding, to create forms and workflows.

TilliT is hosted on AWS, which has the inherent benefits of the cloud. These include speed to deploy and change, seamless upgrades, and professional-grade cybersecurity. The system connects to a virtual or physical low-code edge device to connect to automation or equipment. All of this fosters a fast time to benefit.

Analytics

TilliT includes several types of standard reports: activity, production, dashboards, advanced analytics, and more. Reporting and visualization can serve operators and supervisors, plant managers, and others who need an overview of performance. Customers build dashboards with pre-built cubes. In addition to their own dashboarding, they also OEM AWS’ QuickSight BI tools.

TilliT can use an LLM to build forms and SOPs automatically. These are excellent uses of LLMs’ strength in processing language-based information.

Two new features of note also leverage AI.

- Heads-up notes for the operator are based on AWS Bedrock, which pulls from recent examples and trends about what might go wrong.

- Shift handover summary of what the previous shift did with any issues, plus what the coming shift is due to make.

Customer Successes

Many Australian winemakers already use TilliT. Other Customers in beverages, food CPG, consumer durables, and industrial equipment are also using it successfully. Some large companies are also customers: Schneider Electric is using it to optimize injection molding operations, and Carlsberg is replacing a more traditional MES and IIoT platform with TilliT across its 80+ site global brewing footprint.

- A vegetable processor uses an activity report to quickly get an overview of their high-volume operation’s passes, fails, expires, and skips.

- One customer who took over a year to deploy a traditional MES did it in five months with TilliT.

- A manufacturer of kitchen sinks applied scheduling, execution, quality, safety, and SOPs with wireless IIoT devices and saw a 25% reduction in raw materials and a 10% reduction in finished goods while increasing production by over 4%. They saved a planning resource and reduced changeover time by 15%.

Roima Digital Thread

The acquisition of TilliT is part of a roll-up play for mature manufacturing solution provider Roima. A long-time implementation partner to AVEVA and others, Roima has been increasing their focus towards delivering their own software technologies to the global manufacturing industry after several acquisitions since 2016. The vision is to create a digital thread for visibility and control from product innovation (PLM) to integrated business planning (IBP) to customer management (CRM/CPQ) to digital commerce and product twin, to WMS and MES.

This is an ambitious vision, and achieving it will depend on how well Roima manages the many acquisitions and the increased focus on a unified multi-tenant platform for the industry. Another key factor will be how well its WIRE integration middleware can overcome gaps and create the data and information flows to connect this thread. Yet another open question is whether the private equity backers will have the patience to support everything needed to be profitable in the comparatively conservative and slower-moving manufacturing markets.

Looking Forward

We appreciate the lightweight low-code approach, particularly for the consumer goods segments TilliT has traditionally served. We also like the bottom-up approach to pulling tribal knowledge to build the value map. TilliT has plans to expand AI across its functions.

We look forward to following the progress of TilliT and Roima’s software suite. Thank you, James Balzary, for introducing us to your modern approach to operations software.