A quick peek into some research on … closing the loop on product innovation through an integrated ERP-PLM strategy.  This paper furthers past research on The Complementary Roles of ERP and PLM and earlier research on how integration between these two enterprise systems is maturing in the Evolving Roles of ERP and PLM. The topic of how manufacturers can best leverage ERP and PLM systems is one that I continue to get questions on, and I hope that this paper, Issue in Focus: The Integrated ERP-PLM Strategy, helps further the conversation. I should also point to a good discussion on Oleg’s PLM Twine generated by my last research on ERP and PLM, there are some good comments made there.

This paper furthers past research on The Complementary Roles of ERP and PLM and earlier research on how integration between these two enterprise systems is maturing in the Evolving Roles of ERP and PLM. The topic of how manufacturers can best leverage ERP and PLM systems is one that I continue to get questions on, and I hope that this paper, Issue in Focus: The Integrated ERP-PLM Strategy, helps further the conversation. I should also point to a good discussion on Oleg’s PLM Twine generated by my last research on ERP and PLM, there are some good comments made there.

The Research Findings

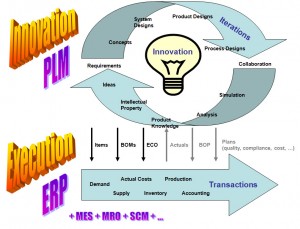

At the risk of being redundant, the paper reconfirms the primary roles of ERP and PLM:

- PLM – PLM focuses on product innovation, and is designed to help manufacturers design, develop, and launch profitable products.

- ERP – ERP’s role is executing the business of manufacturing, supporting the business of planning and managing the execution cycle.

To many these may seem to be an obvious statements, but I still hear confusion in the manufacturing community. This is particularly true as ERP companies introduce PLM solutions. That is why I clearly “Busted“ the myth that PLM is a module of ERP in my Mythbusting ERP-PLM Integration post.

To many these may seem to be an obvious statements, but I still hear confusion in the manufacturing community. This is particularly true as ERP companies introduce PLM solutions. That is why I clearly “Busted“ the myth that PLM is a module of ERP in my Mythbusting ERP-PLM Integration post.

So what is new in this report? A focus on closed loop innovation. Here are the key points that I hope people will take away from the research:

- Innovation is not limited to Engineering – Manufacturing, Service, and other departments innovate too. They change processes and make minor product changes for service or manufacturability to keep things working smoothly. These smaller, day-to-day innovations are frequently not communicated back to Engineering, and are therefore implemented inconsistently and not designed into the next generation of products. I recognize that this is not as prevalent in all industries (due to regulation), but the result is a disconnect between what was designed and what is built and in the field.

- Companies are not Confident Enough to Introduce Changes Rapidly – Many companies do not have a change management process that allows them to rapidly improve their product. Engineering changes are held up into batches or delayed because manufacturers lack the ability to clearly communicate changes to Manufacturing and the supply chain without disruption. The result here is delayed time to market for cost reduction, quality improvements, and minor product enhancements. Or, companies push forward anyway and end up with scrap, rework, and unhappy customers.

A well integrated manufacturing systems environment can help companies overcome these two issues. Closing the loop (through integration) allows companies to rapidly introduce continuous improvements, and keep designs in sync across departments and the product lifecycle.

Implications for Manufacturers

For manufacturers, integrating ERP and PLM is becoming more commonplace. This is good news. Of course, not everybody has PLM in place yet, although most have an ERP (or more than one in many cases, but that is a different story). Unfortunately, I continue to see companies make ERP and PLM choices tactically instead of strategically. I discussed one example of this in Choosing an ERP to fit PLM. This leads to two other points that I hope manufacturers will take away from this research:

- ERP and PLM strategies are too important to be technology-led decisions, and should be addressed in a process-centric approach.

- Recognizing that both ERP and PLM are critical to product profitability, manufacturers must be uncompromising on the needs of these two systems.

As I say in the final recommendations, “Choose the right ERP and PLM solutions, making sure they meet your company, industry, and manufacturing model requirements.” Get the right ERP and PLM systems first. Focus first on getting software that meets the innovation and execution needs of your business. It is better if those solutions are “integration-capable” through current technologies (SOA, XML, API, etc.). Ideally, the solutions come pre-integrated by the vendors. But integration has to be a secondary set of requirements behind functional capability.

So that was a quick peek into some recent research on integrating ERP and PLM to close the loop on product innovation, I hope you found it interesting. Does the research reflect your experiences? Do you see it differently? Let us know what it looks like from your perspective.

Please feel free to review more free research and white papers about PLM and other enterprise software for manufacturers from Tech-Clarity.