I’ve had the chance to speak with Configit over the years and Michelle Boucher and I checked in for an update. Configit started as a spinoff from the IT University of Copenhagen and is a long-time player in the product configuration market. Their product, Configit ACE, is a product configuration engine that manages and executes product configurations for complex manufactured goods and is now offered on the cloud in a SaaS model. It can be deployed as part of an integrated configuration solution or with Configit’s supporting CPQ (configure price quote) Configit Quote, and Configit will be offering a product configuration application, Ace Configurator, in an upcoming release. Configit has a strong following in a variety of manufacturers including very advanced, large companies.

I’ve had the chance to speak with Configit over the years and Michelle Boucher and I checked in for an update. Configit started as a spinoff from the IT University of Copenhagen and is a long-time player in the product configuration market. Their product, Configit ACE, is a product configuration engine that manages and executes product configurations for complex manufactured goods and is now offered on the cloud in a SaaS model. It can be deployed as part of an integrated configuration solution or with Configit’s supporting CPQ (configure price quote) Configit Quote, and Configit will be offering a product configuration application, Ace Configurator, in an upcoming release. Configit has a strong following in a variety of manufacturers including very advanced, large companies.

Some Background

I’ve always had a special interest in product configurators, starting in the days when I implemented one at a number of small to midsized manufacturers. Solving configuration problems for my clients was challenging because it is inherently a cross-departmental issue and requires a combination of strategy and technology. Since that time, I’ve been fortunate to research and report on configurators of all styles from CPQ (configure price quote) solutions to support assemble-to-order (ATO) and make-to-order (MTO) all the way to rules and constraint-based engineering automation solutions for more engineer-to-order (ETO) products. Michelle also takes a special interest in configurators, making it an active conversation with the Configit team.

Configit’s Unique Virtual Tabulation Approach

Configit is interesting because they don’t follow a “me too” approach in their configuration methodology. I first learned of their “virtual tabulation” approach in 2007 and it continues to be their differentiator today. The approach consists of determining all of the valid configurations based on a model and rules. They do this by “pre-compiling” all possible valid combinations of features based on the rules and constraints defined in the product model in a process they call “Virtual Tabulation.” Then, the configuration can be accessed from the table in real-time when the product is configured using a full or partial feature list. While some tools interpret rules or constraints at configuration time, Configit develops a table that contains all valid combinations and resulting configurations. This makes configuration highly performant in a real-time scenario. It also allows them to manage very complex products, including systems-level configurations that span mechanical, electrical, and software configurations. Companies that have a very large number of features and options that may have tried and failed with CPQ solutions may find this a more feasible approach.

Managing the Configuration Lifecycle

Managing the Configuration Lifecycle

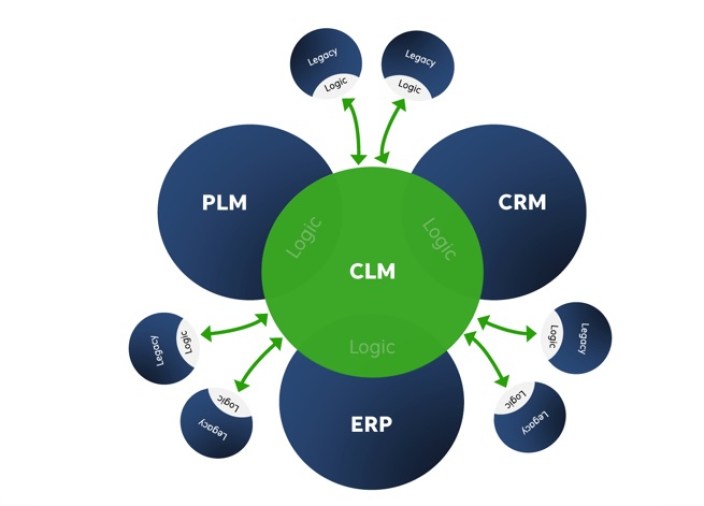

Another key difference is the focus on Configuration Lifecycle Management (CLM). The approach is intended to go beyond creating a valid configured order to make sure that what’s designed and developed is aligned through sales to service and operations. As Configit’s VP Product Management Henrik Hulgaard points out, this alignment is becoming more important as companies adopt a Product as a Service (PaaS) business model. To align the configuration across the lifecycle, they create a model that spans engineering, sales, service, and manufacturing.

Typically, their customers have configurable engineering information in PLM and sometimes multiple PLM systems. Then they have configurable manufacturing information in ERP, while the configuration sales information is in a CPQ system. The different systems and formats have made managing the end-to-end configuration process difficult. Configit’s central product model ties the information across all systems to manage the configuration options end-to-end.

The approach provides their customers with the flexibility to respond to internal and external changes. For example, when a new product is released, they can assess which new base configurations need to be priced or identify if there are new combinations they need to simulate or validate. Externally, if customers must comply with new regulations, they can identify which combination can no longer be offered in specific regions.

Adopting Configit

Configit can be implemented in a variety of ways depending on what the manufacturer needs, including acting as a component in an existing product configuration system ecosystem or as a more comprehensive solution. It can also be adopted in a broader CLM approach to coordinate configuration across the lifecycle, but there are options to start small to solve more focused problems and grow over time. Modeling and implementation are part of the implementation strategy, where Configit brings a methodology and not just technology. Their implementations also tend to integrate across multiple systems that contain information that either feeds or receives crucial configuration data, including close ties with Product Lifecycle Management (PLM).

Configit can be implemented in a variety of ways depending on what the manufacturer needs, including acting as a component in an existing product configuration system ecosystem or as a more comprehensive solution. It can also be adopted in a broader CLM approach to coordinate configuration across the lifecycle, but there are options to start small to solve more focused problems and grow over time. Modeling and implementation are part of the implementation strategy, where Configit brings a methodology and not just technology. Their implementations also tend to integrate across multiple systems that contain information that either feeds or receives crucial configuration data, including close ties with Product Lifecycle Management (PLM).

Thank you Henrik Hulgaard , Daniel Joseph Barry, Kirsten Pflomm, and Diana Diaz for the briefings.