How can a manufacturer ensure their frontline workers have a seamless experience on one device? Dozuki recommends putting everything into their platform on a mobile device. Their platform has knowledge management, learning courses, digital operational workflows, and collaboration all in one system. It drives performance and continuous improvement (CI) for safety, quality, and production. We were excited to hear of the continued momentum in our recent briefing with Dozuki.

Early Connected Workforce Pioneer

Dozuki was founded in 2011 to deliver digital enablement to frontline workers, before the term connected worker platform existed. They now have 520 customers across nearly every type of manufacturing business. Dozuki says customers have incorporated 8,900,000 documents. For knowledge management and learning, one of the foundations for success is ingesting documents, including training materials, standard operating procedures (SOPs), specifications, and work instructions.

What these Dozuki’s diverse manufacturing customers have in common are challenges: workforce turnover, quality, safety, and compliance. The array of industries and company sizes is vast, from consumer to industrial and small to large.

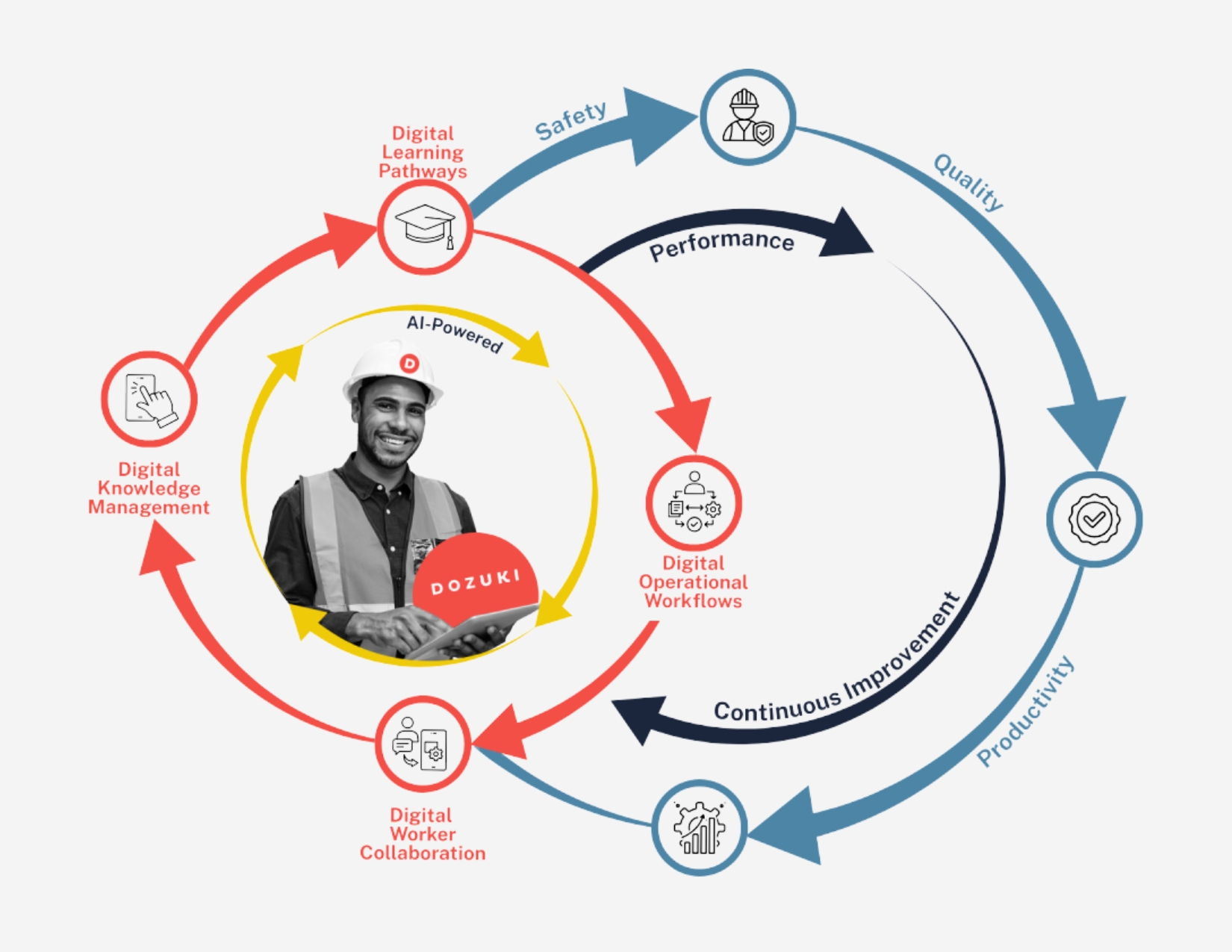

One System, Many Functions

Dozuki’s vision is to have a single system that serves all the needs of frontline workers. As a SaaS system, a connection to the internet and a mobile device are all a customer needs to provision for users. It does not replace other systems but integrates with them as a front-end for the workers.

Dozuki categorizes the functionality of its system into several major areas:

- Knowledge Management – digital standard work, knowledge access, version control, AI-generated standard work based on narrated videos and existing documents, and translation into over 100 languages

- Learning Pathways – Training, assessments, a training matrix, skills matrix, and integration to LMS/HRIS, as well as SCORM external training content

- Operational Workflows – digital forms, quality checks, work order reporting, supervisor sign-offs, and integration to other systems such as QMS, MES, and CMMS for reporting

- Worker Collaboration involves worker-led feedback on standard work, change management, change awareness, and answers to workers’ questions, which feeds CI initiatives

- Proactive AI Analytics and Insights – the system has analytics for knowledge management, learning pathways, and operational workflows, as well as compliance, engagement, and enterprise-level reporting across multiple facilities

The Dozuki system uses templates for each function and can provide suggestions and pointers to where more training might be needed. It also creates an engaged workforce with a culture of connectivity and CI across knowledge, learning, execution, and collaboration. Dozuki provides one seamless experience for the workers. It includes not only their learning and instructions but also a QR code scanner, digital forms, annotated photos, and videos. This helps them comprehend the task at a glance—in their native language.

Strong Benefits

Capturing tribal knowledge is difficult to measure, so most customers start with a pilot to show how it works and gain buy-in from the workers. Dozuki says their customers report an average of 50% savings in capturing knowledge and documenting processes. With the 2024 addition of CreatorPro AI, which can create fresh guides from a narrated video or existing document upload, time savings go up. The additions to it this year enable it to extrapolate from existing documents so that time savings can be as high as 80-90%. New hire training can be reduced by 75% and better meet the expectations of younger digital-native workers.

3M reduced quality issues even as much of its workforce is retiring. They report a 50% reduction in process document creation and a 40% reduction in onboarding time for new hires. In addition, they gained a 40% reduction in changeover times.

General Mills counteracted a large retiring workforce by implementing Dozuki. They report a 75% reduction in training time for new hires and a 65% reduction in changeover times. Key operations metrics saw dramatic jumps of 150% for production efficiency and 67% increase in mean time between failures (MTBF).

Caterpillar has standardized on Dozuki across multiple facilities and many workers for quality. They gained $62K per line annual savings in reduced downtime and $10K annual savings per machine on equipment repair. They also achieved a 75% reduction in process revision time.

Software and Services Partner

While some SaaS platforms are self-service for the customer to set up and deploy, one of Dozuki’s core differentiators is that they also provide services. In addition to a dedicated team for implementation support, they help convert or create documents. Not surprisingly, the services team also does integration work with other systems. The company takes a long-term partnership approach.

Looking Forward

The market has caught up with Dozuki, and they are building a stronger marketing presence. In the future, we expect AI to improve every area of the offering. Think about the power of AI to help discover the knowledge a worker needs and decide the best guidance format based on the person and task. In the learning area, personalized learning and adaptive assessments are on deck. AI in the operational workflows could enable anomaly detection and dynamic task assignments. Worker collaboration stands to gain remote expert guidance and gamification.

Thank you, Leslie Bloom, for briefing our Julie Fraser and Rick Franzosa! We look forward to following your progress in the market.