Supply Chain Collaboration

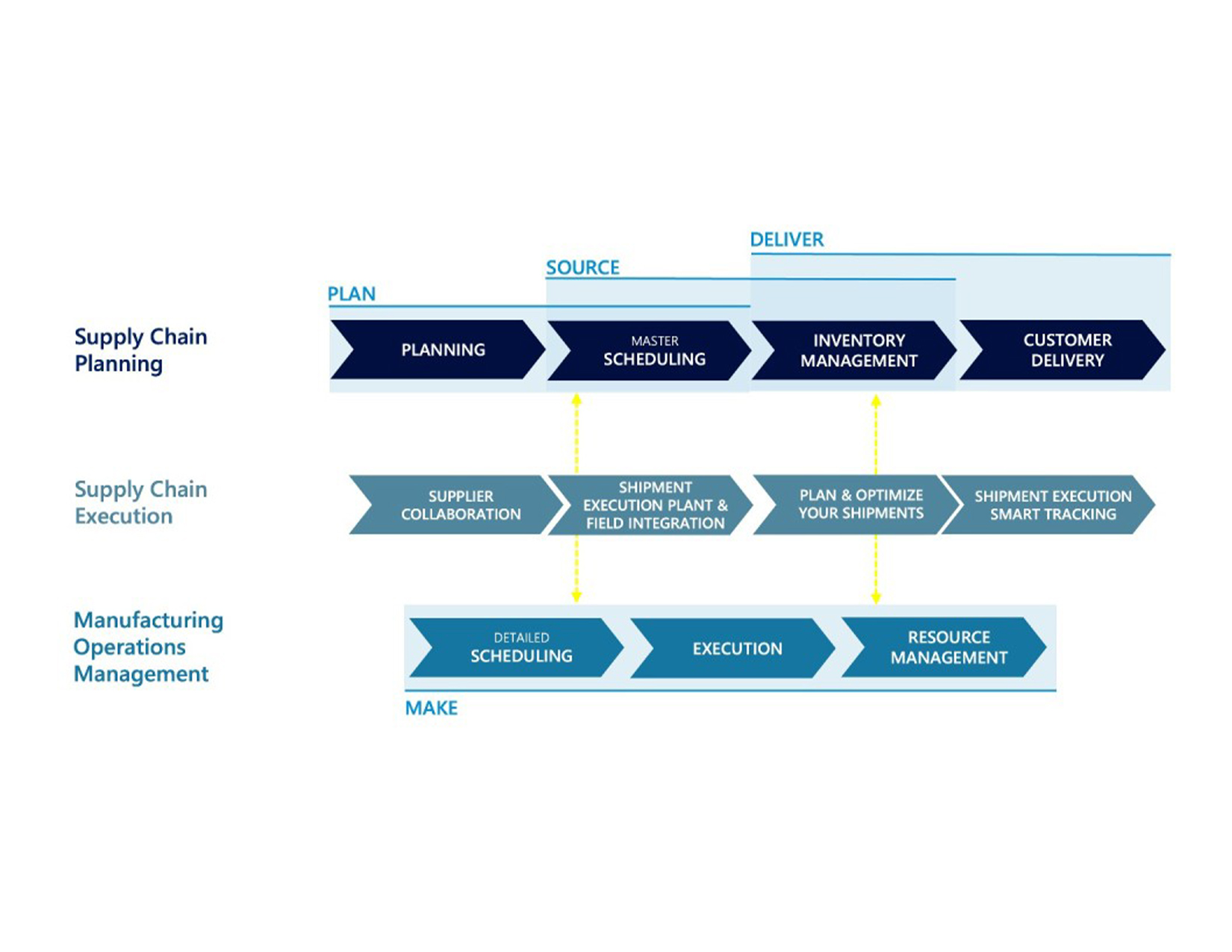

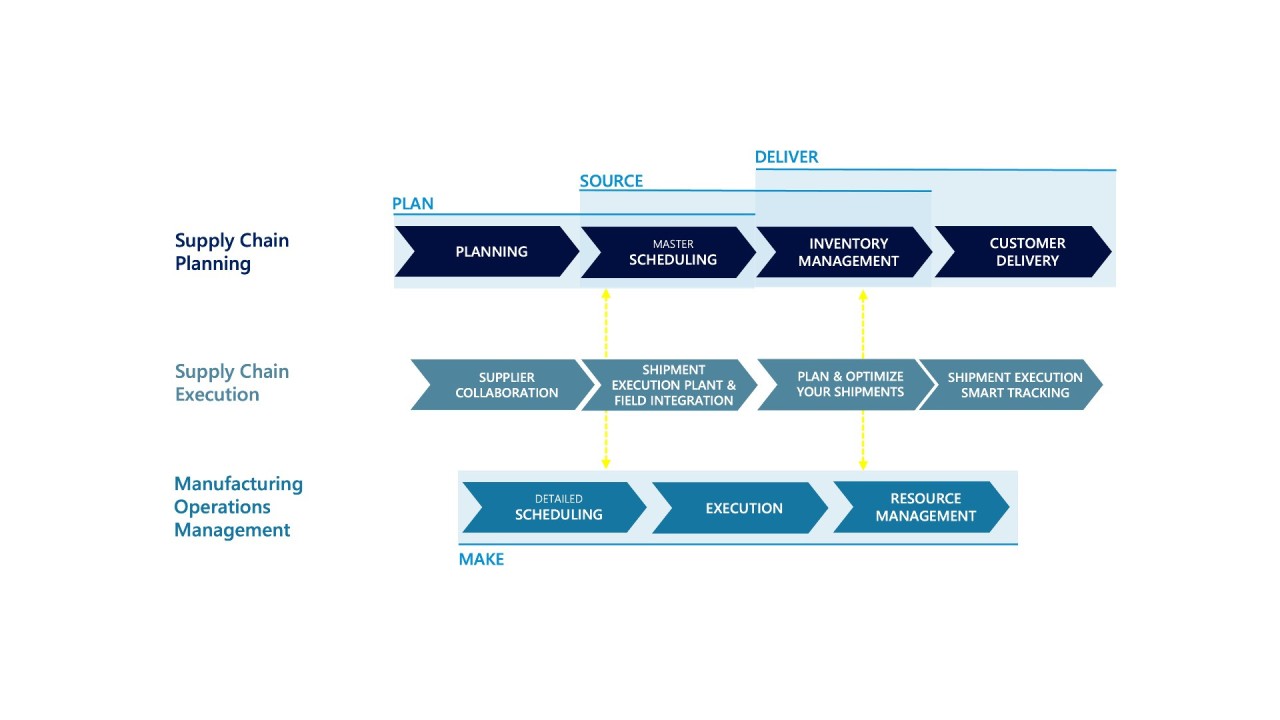

Supply chain planning and execution and manufacturing operations have often been separate groups with disconnected software applications. Yet they are all part of one supply chain, one flow of data and materials (plan-source-make-deliver). sedApta Group offers software to gain visibility, collaboration, and orchestration across all of those areas.

We caught up with sedApta just as their relationship with Elisa IndustrIQ shifted from being a partner to becoming part of the company. We see that as a good move. It should afford sedApta opportunities to expand globally, bolster AI, and extend and deepen functionality such as warehouse management by leveraging sister companies. The acquisition builds out supply chain capabilities for Elisa, which is actively acquiring companies for a comprehensive and modular set of manufacturing software.

Origins and Leadership

It turns out that MES pioneer Giorgio Cuttica was sedApta’s CEO, nurturing another fascinating software company in the operations space! (We met him as he brought Orsi, now Siemens Simatic IT MES, into the global market.) In 2014, he found a successful planning and scheduling product in Italy and modernized it.

With Giorgio’s manufacturing operations and MES background, the company saw the need for tighter working between supply chain planning, manufacturing operations, and supply chain execution. Particularly as uncertainty has grown in supply chains worldwide, this integration is increasingly important.

Now that the acquisition is final, Elisa has named Benedetta Cuttica CEO. She was formerly the CTO and has deep roots in the sedApta software.

Broad Scope of Natively-Integrated Functions

sedApta’s concept is that planning must be more integrated with what’s happening in manufacturing, distribution centers, and transportation, and it must all be aligned with customer and market demand. We agree that’s important and has historically been difficult for companies to achieve.

sedApta has invested heavily in R&D over the past 10 years. While other companies have been acquiring, sedApta has built out a comprehensive suite with native integration and a shared data lake. This delivers some significant benefits for collaboration and orchestration. In addition to expanding the overall set of modules and functionality, they have also created industry-specific functionality with libraries and best practices.

Some differentiating capabilities in sedApta’s integrated suite include a simulation-based control tower, a supplier portal for reporting progress collaboratively, multi-plant planning and production visibility, volume and operations planning (V&OP) that extends beyond traditional sales data of S&OP, and a process digital twin developed in collaboration with Elisa.

Customers Served

Different industries have different supply chain issues. sedApta’s vertical focus and libraries are:

- discrete manufacturing

- food and beverage

- fashion and luxury goods

- process manufacturing

Food and beverage tends to be short-term around promotions and large retail customers; fashion is driven by short seasons and outsourced production. Discrete and process may be more stable. Within those, they have often served both final OEMs and suppliers to them, so the focus shifts from long-term supply and demand planning to short-term, reactive planning.

The sedApta solution is well suited to middle-market companies with revenue between $200M and $3 billion. These companies may not be interested in investing in some of the other well-known supply chain software suites designed and priced for large enterprises. sedApta has also invested heavily in ERP integration to ensure data flows smoothly.

Special Tech Touches

sedApta has a composable web interface it calls bricks, all on a shared database. Once they create an integration or a user interface, customers can reuse it. The control tower is built with bricks, for example.

Open interfaces enable the software to use variables from external sources. This is crucial for many industries’ supply chains where supplier and customer data, weather feeds, and economic sustainability data can greatly impact the accuracy of forecasts and market signals. This can also enable sustainability data to ensure compliance and traceability.

AI is laced into nearly every product. Algorithms have always been the core of supply chain planning and scheduling, but now some of that logic is readable to explain why the system made the decisions or created the sequences it did. The Elisa Bot is a copilot to improve the planning cycle. A demand-sensing solution will improve longer-term forecasting.

Extending the Reach

sedApta has many partners. Some are global implementation partners, such as KPMG working in the Caribbean and Asia. Others, such as Sage X3, white-label parts of the product suite. The company also has some resellers.

Under new parent Elisa, sedApta’s reach will extend beyond its roots in Europe. While its customers have sites outside Europe using sedApta today, it will now build go-to-market capabilities.

Thank you, Duncan Chapple, for setting up the meeting, and Pietro Cuttica for taking the time to update me on sedApta! I’m excited to follow your supply chain progress as part of Elisa IndustrIQ!