Should emerging companies implement factory software before product lifecycle software? Sometimes. Julie Fraser’s blog post for the First Resonance site explores the strengths of modern MES and when it might be the priority application to implement, even when PLM is not yet in place.

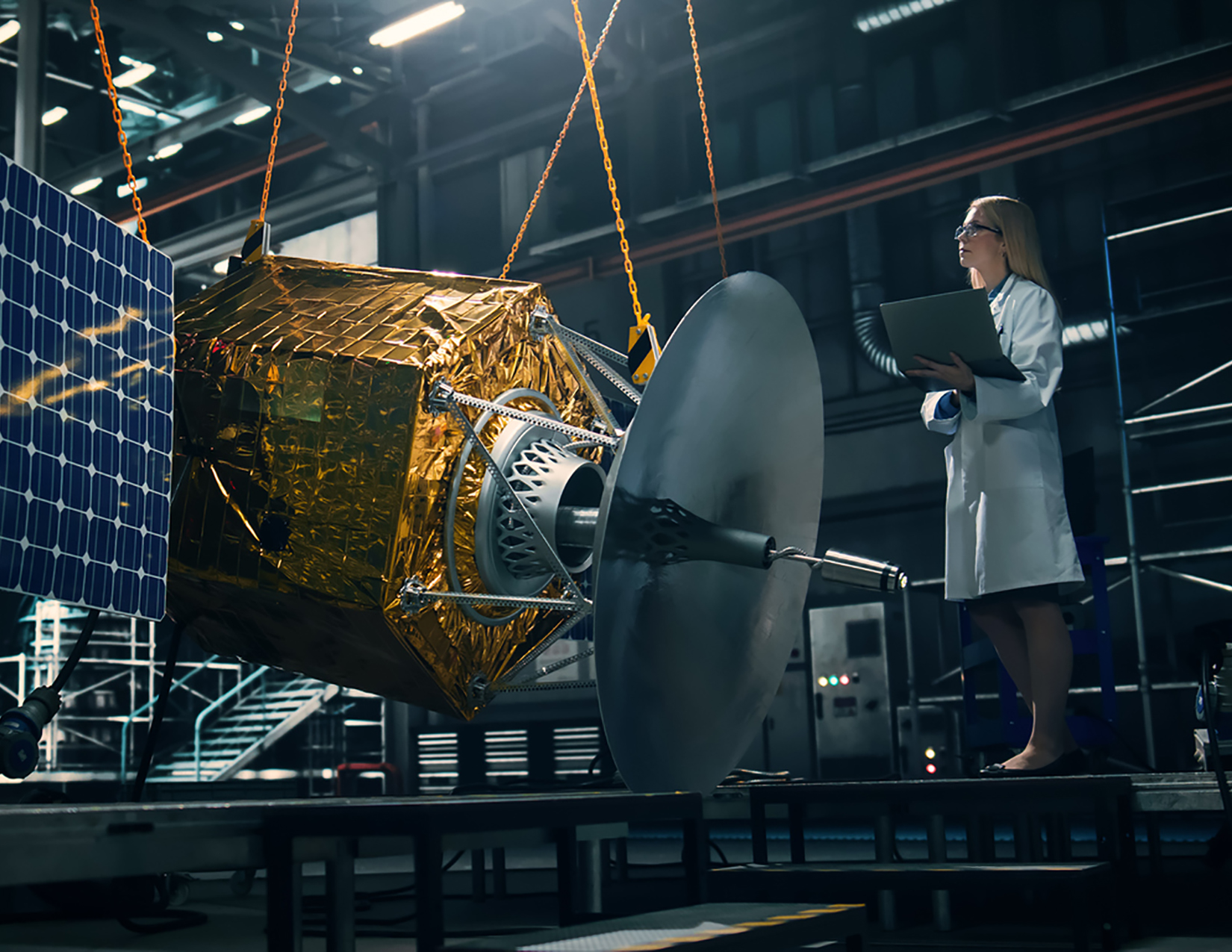

Software for a Manufacturing Business

Young companies, especially those with breakthrough products, typically start as R&D operations. This blog post explains what MES is – and how modern factory systems are often doing more than just guiding and tracking the operation. It also points to why MES is crucial, and how some of the manufacturing-focused capabilities of other systems might fall short of what a company needs to manufacture profitably.

Scaling the business for reliable, cost-efficient manufacturing needs many types of software, including typically ERP, PDM and PLM, and MES. This short piece includes a view of what types of activities manufacturers need software to support.

Is MES Next?

Because many companies do not have factory software in their early stages, this blog describes the strengths of MES. It also points to some capabilities that modern factory software has that older MES might not have had. The goal is to educate the reader about what to expect from such a factory system investment.

The post even includes key questions to ask to help decide whether MES is the next best step. These point to pain points, prerequisites, and alignment with strategy and stage of the business. We advocate for ensuring all disciplines are at the table along with top executives who have the full purview and own the strategy software must support.

Thanks to First Resonance for their support or our research. Read the full guest blog post on the First Resonance website.