Making plant floor software more straightforward to use, rollout, maintain, and sustain is a worthy endeavor. The fourth annual release of the GE Digital Proficy portfolio as an integrated release was packed! Updates range from expanding industry fit to architecture for enterprise rollout, cloud everywhere, composability, consistency for connected workers, sustainability functionality, and pre-built analytics for common needs.

Making plant floor software more straightforward to use, rollout, maintain, and sustain is a worthy endeavor. The fourth annual release of the GE Digital Proficy portfolio as an integrated release was packed! Updates range from expanding industry fit to architecture for enterprise rollout, cloud everywhere, composability, consistency for connected workers, sustainability functionality, and pre-built analytics for common needs.

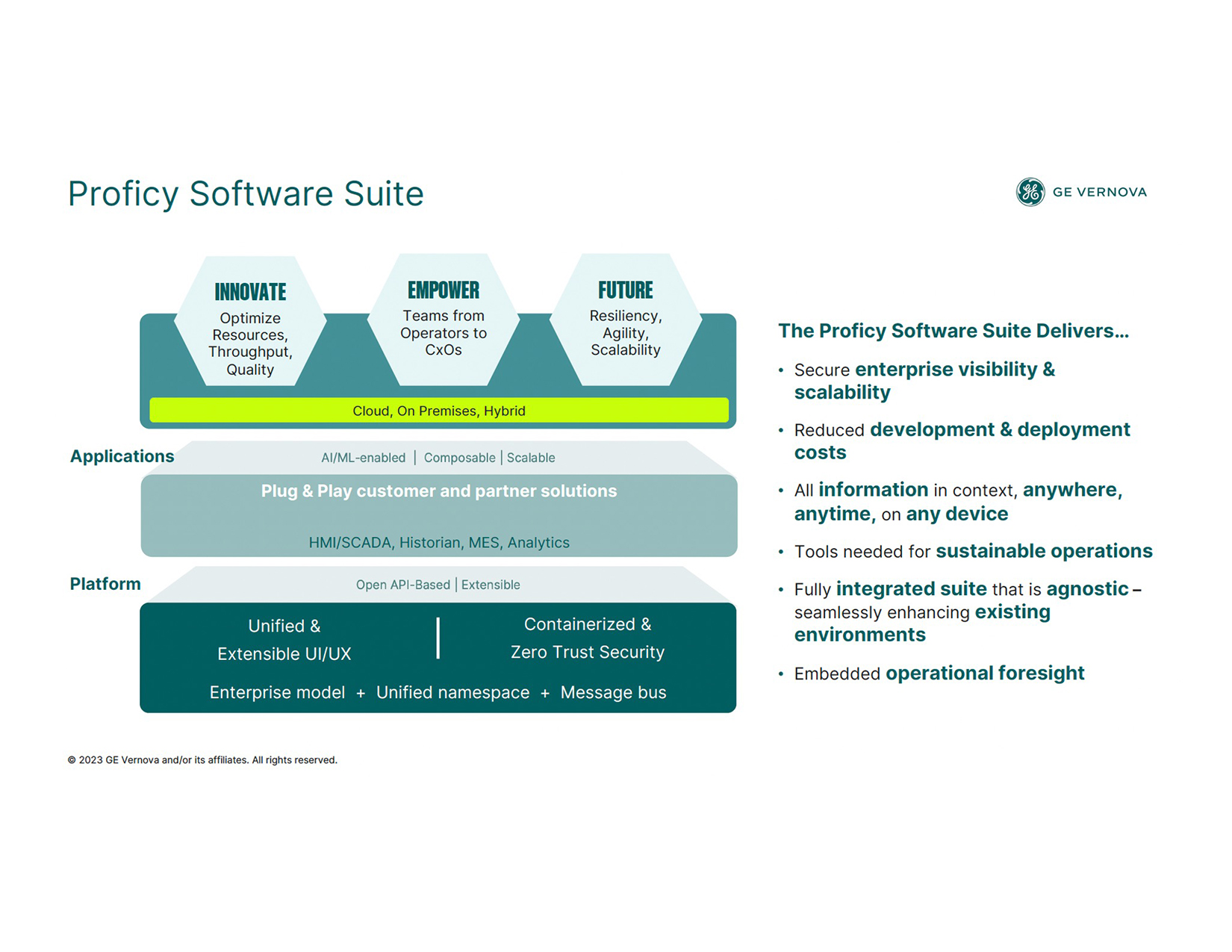

Jim Brown and Julie Fraser had a chance to catch up with the GE Digital product management team for a preview of the Proficy 2024 unified launch. Unified is a relatively new capability for Proficy, with cloud or hybrid hosting, a common user experience (UX), and common administration. That’s rare, since this suite includes not only comprehensive MES and plant applications, but also historian, automation software and Sustainability software.

Some of the highlights are:

Coherent, flexible architecture: Historian and MES are entirely rewritten to be containerized on the same unified namespace (UNS). Other components of this model are a data model, support for a range of databusses including MQTT, OPS-UA and more, and a directory service. We see this as a solid approach for the software to stay useful at enterprise scale over the long term.

Connected worker consistency: IT are not the only ones with new capabilities. Operations Hub supports operators, supervisors, technicians, and other connected workers. It lets the customers compose applications as they wish behind a single UI. Applications from HMI, dashboards, engineering analytics, and MES all use containers and Operations Hub to appear in a consistent way. It aims to work even beyond the Proficy suite.

Enterprise scale: Cloud, on-prem, or hybrid hosting is working into most of this suite. Customers can now pipe data into data lakes and an array of analytics tools. The file storage approach means sending even millions of data points per second from OT tags across multiple plants is possible. Configuration Hub is central to the ability of a center of expertise (CoE) to manage all of these applications seamlessly. GE reports that one automotive customer is automatically building tag databases for their many plants retooling for EV production, and it’s taking only weeks to build HMI/SCADA databases. Licensing by tags also enables customer flexibility to deploy as needed.

Expanded discrete industry support: GE Digital is working with GE Aviation to support complex low-volume discrete industries such as A&D (Proficy has long had a strong base in automotive). This industry has only a few successful MES who offer what they need in engineering change and dispatching, so this market entry is welcome.

Expanded analytics: More of the applications now have embedded issue-specific analytics already included. The suite also offers customers the ability to build their own analytics models. Sustainability is one such area, based on Vernova’s focus. PID loop health is another. Alarm management in the automation suite has been upgraded to reduce distribution during alarm floors, and new capabilities for troubleshooting alarms are included also.

All of these new capabilities are in a coherent yet open suite of products. Customers can benefit across OT, IT, sustainability, and plant operations. We see how this would put GE Digital in a strong position as the spin-off of GE Vernova approaches.

Thank you, Steve Pavlovsky, Prasad Pai, Joe Gerstl, and Ben Whiteman, for an excellent overview of the new possibilities in Proficy. Thanks, Carter Conway and Spenser Murray, for setting up the briefing for us. We will look forward to more news as Proficy continues to leverage technology advances and meet market shifts.

For related content, read our previous insights on how GE Aims to Operationalize Sustainability and how they plan to Enhance MES for TCO and Flexibility.