What is holding companies back from Industry 4.0 project and initiative success? A few things: integration for data flows, speed to deploy software consistently to multiple sites for scalability, disconnects between corporate IT mandates and in-the-plant needs, and projects that don’t fit the budget of smaller plants and companies. Recently, Jim Brown and Julie Fraser learned how IndustryApps aims to alleviate those issues and democratize access to best-in-class Industry 4.0 approaches.

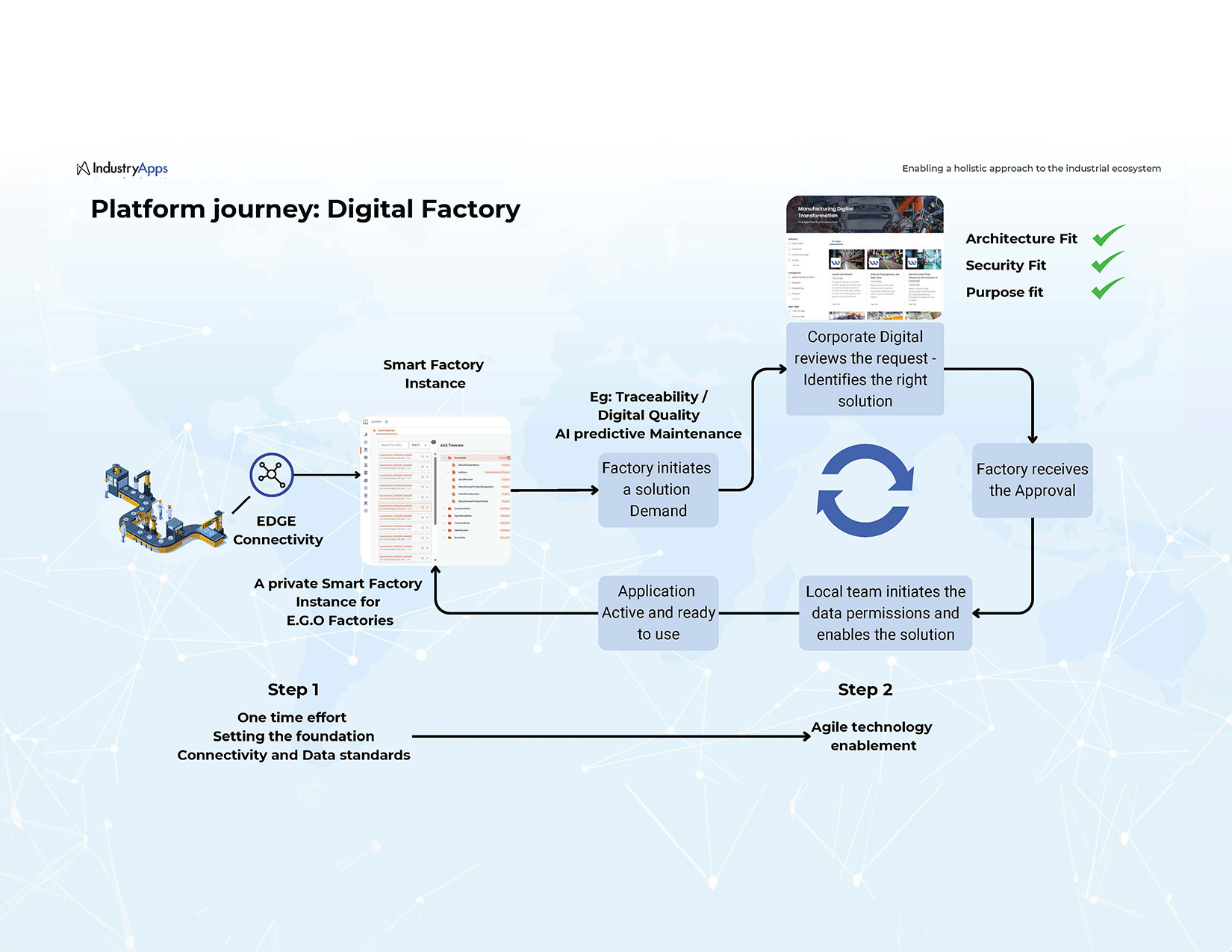

How? By building an industrial dataspace using industry standards, and inviting software application providers to use this platform to expand their reach and speed time-to-value for their projects. Manufacturers subscribe to the apps they need at any time. The OpEx approach lowers the barrier to entry and the cloud-based hosting speeds implementation.

Aiming to Democratize Industry 4.0

IndustryApps’ stated mission is to make Industry 4.0 simple for all industrial businesses. They envision their single platform as a foundation for digital transformation. The platform is based on digital twin standards. With this platform, manufacturers can create digital twins for machines and products. The platform is a secured, private application enablement environment. Beyond the platform, the AppStore of proven solutions across the broad array of functional needs creates new opportunities for manufacturers of all sizes and industries.

Ecosystem

Creating an ecosystem for other software companies has the potential to accelerate growth for IndustryApps – and rapidly expand value for manufacturers who use it. There are already 80 solution providers with software in the AppStore. All of these applications use the standard data exchange approach IndustryApps has built into its platform.

Solution providers are interested in participating for several reasons. They get a new channel to market, covering geographies or industries that are hard for them to reach, that provides first-line support. Participating is a driver to adopt the many industry standards at the core of the IndustryApps Platform. These include RAMI 4.0, Asset Administration Shell (AAS) Consortium, ISO/ECLASS for semantics, Open Industry 4.0 Alliance architectures, GAIA-X distributed sovereign data rules, and ISA 95. Many software companies are already adopting these standards to provide customers with more flexibility and better integration. Although it takes a strong commitment from vendors, adopting standards is a path to more complete digital threads and industrial dataspaces.

Industry Origins

The founders began to develop this platform approach while working at Henkel. When Sandeep Sreekumar’s scope expanded to 140 plants, he realized he needed a way to scale and roll out rapidly, plus allow flexible deployment at sites. Developing a platform enabled the bottom-up approach to digitalizing factories. Some of these Henkel factories became lighthouses in the World Economic Forum Industry 4.0 program.

Extend

Manufacturers continually seek to extend their company’s capabilities by leveraging software. New applications from solution providers make up one aspect of the extensibility of IndustryApps. Now, the platform is open for manufacturers to onboard their internally-developed solutions. Manufacturers can subscribe to new apps for a monthly fee and get up and going with minimal training or delay. The connectivity is provided or open to using their own data connectivity layer.

Cybersecurity

Another crucial aspect of Industry 4.0 software is cybersecurity and data protection. With manufacturers increasingly being a target for cyberattacks, this is crucial. Also, when the data may need to flow among multiple companies or departments, the ability to dictate and update access control for each person is vital. Further, the manufacturers always own their own data on the IndustryApps platform and ecosystem.

Thank you, Sandeep Sreekumar, for spending time to update us on your vision and status. We look forward to following IndustryApps’ progress in the market.