How do companies improve profitability by monitoring, analyzing, and optimizing equipment via the Industrial IoT? How has the COVID-19 pandemic impacted their plans? See what our survey of over 200 companies that manufacture, operate, service, sell, distribute, install, and/or integrate equipment finds about how the leaders operate in Tech-Clarity’s Pillars of Machine Monitoring and Optimization.

How do companies improve profitability by monitoring, analyzing, and optimizing equipment via the Industrial IoT? How has the COVID-19 pandemic impacted their plans? See what our survey of over 200 companies that manufacture, operate, service, sell, distribute, install, and/or integrate equipment finds about how the leaders operate in Tech-Clarity’s Pillars of Machine Monitoring and Optimization.

Please enjoy the summary* below. Please visit our sponsor Siemens MindSphere® for the full research (registration required).

Learn more about machine monitoring and optimization and find how to get started by visiting our sponsor, Siemens MindSphere®.

Table of Contents

- Strategies

- Benefits

- Monitoring and Optimization is Transformational

- Challenges

- Impacts of COVID-19

- How Can Companies Improve Performance?

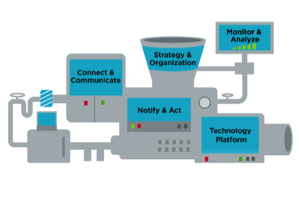

- Pillar 1: Strategy and Organization

- Pillar 2: Connect and Communicate

- Pillar 3: Monitor and Analyze – Prepare Data

- Pillar 3: Monitor and Analyze – Analyze Data

- Pillar 4: Notify and Act

- Pillar 5: Enabling Technology – Systems

- Pillar 5: Enabling Technology – Integration

- Key Findings and Conclusions

- About the Research

- Acknowledgments

Monitoring and Optimization is Transformational

Machine Monitoring Benefits are Strategic

Beyond direct benefits, monitoring equipment via the industrial IoT is the foundation for greater business impact. Most survey takers report that their equipment monitoring strategy is part of one or more broader corporate initiatives. Machine monitoring and optimization supports a variety of important business initiatives including digital transformation, smart manufacturing, and service transformation. It can also help fuel continuous improvement programs such as Six Sigma, as reported by one-half of surveyed companies. Very

few, only 2%, are pursuing it as a standalone strategy.

IoT Machine Monitoring is Essential

Machine monitoring and optimization drives success by fueling digital transformation. A recent, but separate, Tech-Clarity survey shows that more than one-half of manufacturers say digital transformation is “important” if not “critical” to achieving their business strategy. This is particularly true in these challenging times. As evidence, another study finds that the vast majority of companies have either increased their focus and/or accelerated their digital transformation efforts or at least maintained their current level of focus. Machine monitoring is much more than a tactical, operational initiative; it lays the structure for much broader digitalization.

Machine monitoring and optimization drives success by fueling digital transformation. A recent, but separate, Tech-Clarity survey shows that more than one-half of manufacturers say digital transformation is “important” if not “critical” to achieving their business strategy. This is particularly true in these challenging times. As evidence, another study finds that the vast majority of companies have either increased their focus and/or accelerated their digital transformation efforts or at least maintained their current level of focus. Machine monitoring is much more than a tactical, operational initiative; it lays the structure for much broader digitalization.

Key Findings and Conclusions

Companies are Actively Pursuing Machine Monitoring

Over three-quarters (84%) of surveyed companies are pursuing machine monitoring and optimization, and another 13% plan to. Most companies are pursuing it as a part of a larger digital transformation, smart manufacturing, or service transformation initiative; as continuous improvement; or a combination of these.

Machine Monitoring and Optimization Drives Benefits

Companies are pursuing – and achieving – business goals by implementing machine monitoring and optimization. Initiatives to monitor and improve equipment are resulting in improved profitability in the vast majority of companies.

Top Performers Gain More Value from their Approaches

Over one-half (54%) of Top Performers, those that are executing better at our pillars of machine monitoring, report they have significantly improved profitability. These leaders are leveraging best practices and technologies to support machine monitoring and optimization. They are:

- Almost twice as likely to have an executive responsible for their strategy

- More likely to combine machine data with enterprise systems, engineering data, and environmental data in addition to operational systems

- Twice as likely to use prescriptive methods to act on data (although it’s still an emerging practice and only a small percentage have adopted this)

- 50% more likely to initiate actions by notifying operators with push notification in job-specific apps, and 75% more likely to be able to act on information in near real-time

To support this, they are about two-thirds more likely to have fully integrated systems, twice as likely to have a single suite of solutions, and much more likely to leverage an Industrial IoT solution.

The bottom line? Companies that follow best practices across the Pillars of Machine Monitoring and Optimization are more likely to significantly improve their company profitability.

*This summary is an abbreviated version of the research and does not contain the full content. For the full research, please visit our sponsor Siemens MindSphere®.

If you have difficulty obtaining a copy of the research, please contact us.