We had a fascinating update briefing with Gridraster COO/Co-founder Dijam Panigrahi, highlighting the growing potential of XR and spatial computing. When we first spoke with them a couple of years ago, we were excited about their platform and what it offers their application provider partners. Namely, Gridraster provides the infrastructure they need to deliver solutions with remote rendering, precise 3D spatial mapping of virtual objects in mixed reality, and other enablers that unlock the power of the metaverse.

One of the reasons Julie Fraser and I like speaking with Gridraster is that they do quite a bit of work in the aerospace and defense industry. A&D helped pioneer #virtualreality and continues to push the maturity of what mixed reality can do. They have also been leading proponents of digital twins, where Gridraster can provide the granular data underpinning for the industrial metaverse. Of course, it’s hard to discuss XR right now without mentioning Apple. As Dijam told us, “With Apple coming in, the new word is spatial.” The introduction of the Apple Vision Pro created a lot of enthusiasm about the metaverse across industries and should contribute to new use cases and greater adoption.

However, technology is only one part of the equation; gaining real business value is another. Manufacturers are starting to gain more confidence in spatial computing and beginning to achieve real value. Gridraster is working with manufacturers that are applying XR across the product lifecycle, from engineering through support. Some of the critical use cases they’re working with customers and partners on include:

- Improving quality assurance by comparing expected geometry with scanned geometry, whether holographically with headsets or by leveraging other scanners, in near real-time

- Creating high-precision digital twins for existing assets, for example, creating a 3D reconstruction of a physical item without existing 3D designs to support simulation, operations, or training

- Supporting manufacturing by determining the 3D coordinates of a work piece in a robotic work environment to pass along to industrial robots

- Improving maintenance and inspections by scanning with a camera and stitching together multiple scans to create a 3D model to map out an entire interior space without a person physically entering the space

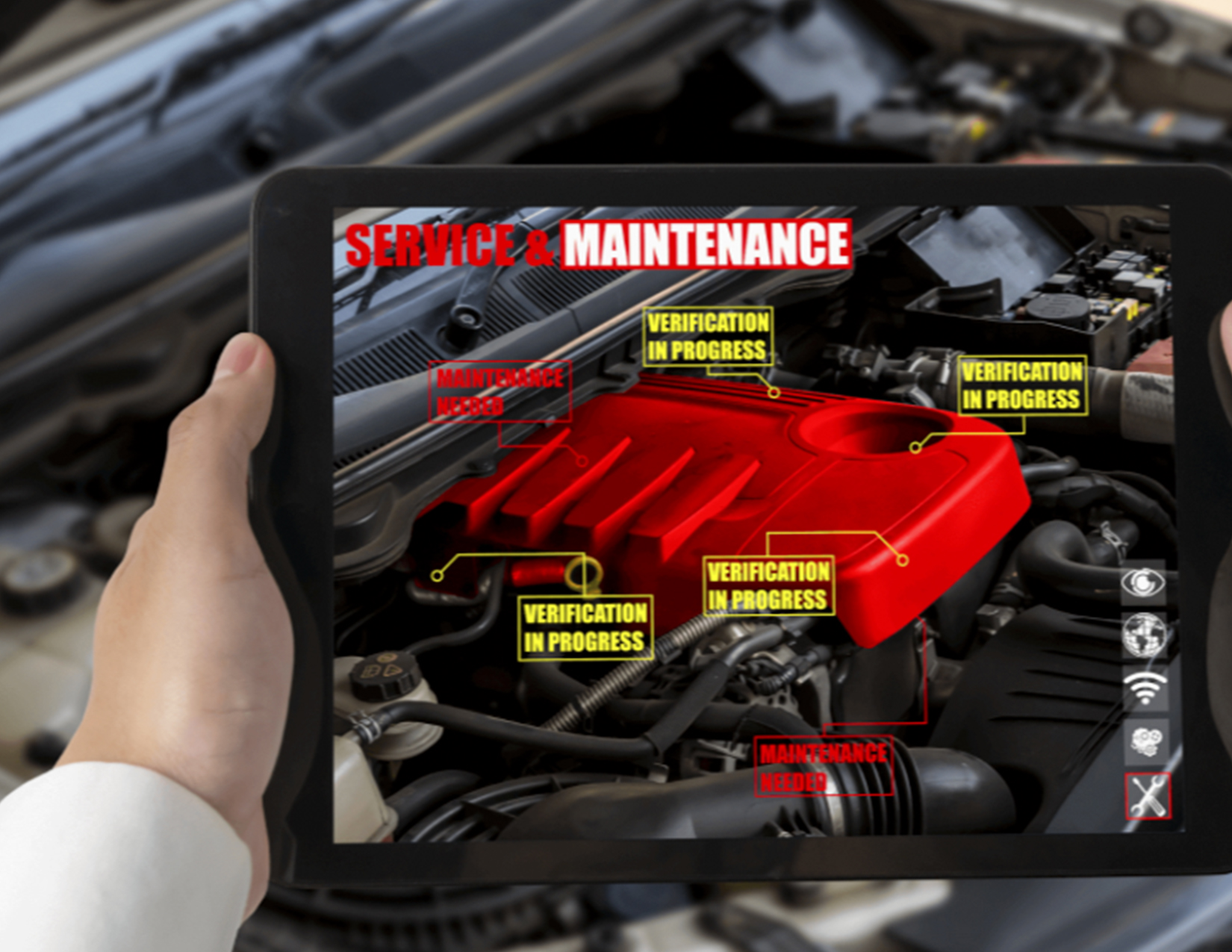

- Supporting maintenance and inspection technicians with active task guidance by overlaying digital instructions over the physical environment

Dijam explained that one of their most compelling capabilities to support these use cases is their ability to capture geometry with millimeter-level accuracy. With this, they can create very precise renderings or compare “as expected” digital models with the scanned truth with high precision and identify discrepancies with very high accuracy.

Our research shows that it may still take some time for XR and the industrial metaverse to become pervasive tools in the manufacturing industries, at least outside of larger companies and industries like automotive and A&D. Still, our discussions with GridRaster Inc. show that the value is available, and we believe the barriers will continue to drop. As devices become more capable, computing power grows, and platforms become more accessible, at least in some part due to the gaming industry, we expect further adoption. Thank you, Dijam Panigrahi to keep us in the “believers” camp for greater adoption – and value – from AI and XR. And thanks to John Sternal for coordinating the discussion.