Can a highly regulated pharmaceutical or biotech company trust AI in their GXP manufacturing operations? Apprentice says yes. In the past year, they have added GenAI for intelligent context-awareness to the Tempo MES / LES / Automation solution. Now, they have added agentic AI to automate production and lab processes further. It might sound like auditors would balk, but Apprentice has built ways to control the agents’ capabilities and validate the system.

Can a highly regulated pharmaceutical or biotech company trust AI in their GXP manufacturing operations? Apprentice says yes. In the past year, they have added GenAI for intelligent context-awareness to the Tempo MES / LES / Automation solution. Now, they have added agentic AI to automate production and lab processes further. It might sound like auditors would balk, but Apprentice has built ways to control the agents’ capabilities and validate the system.

Breaking New Ground – Again

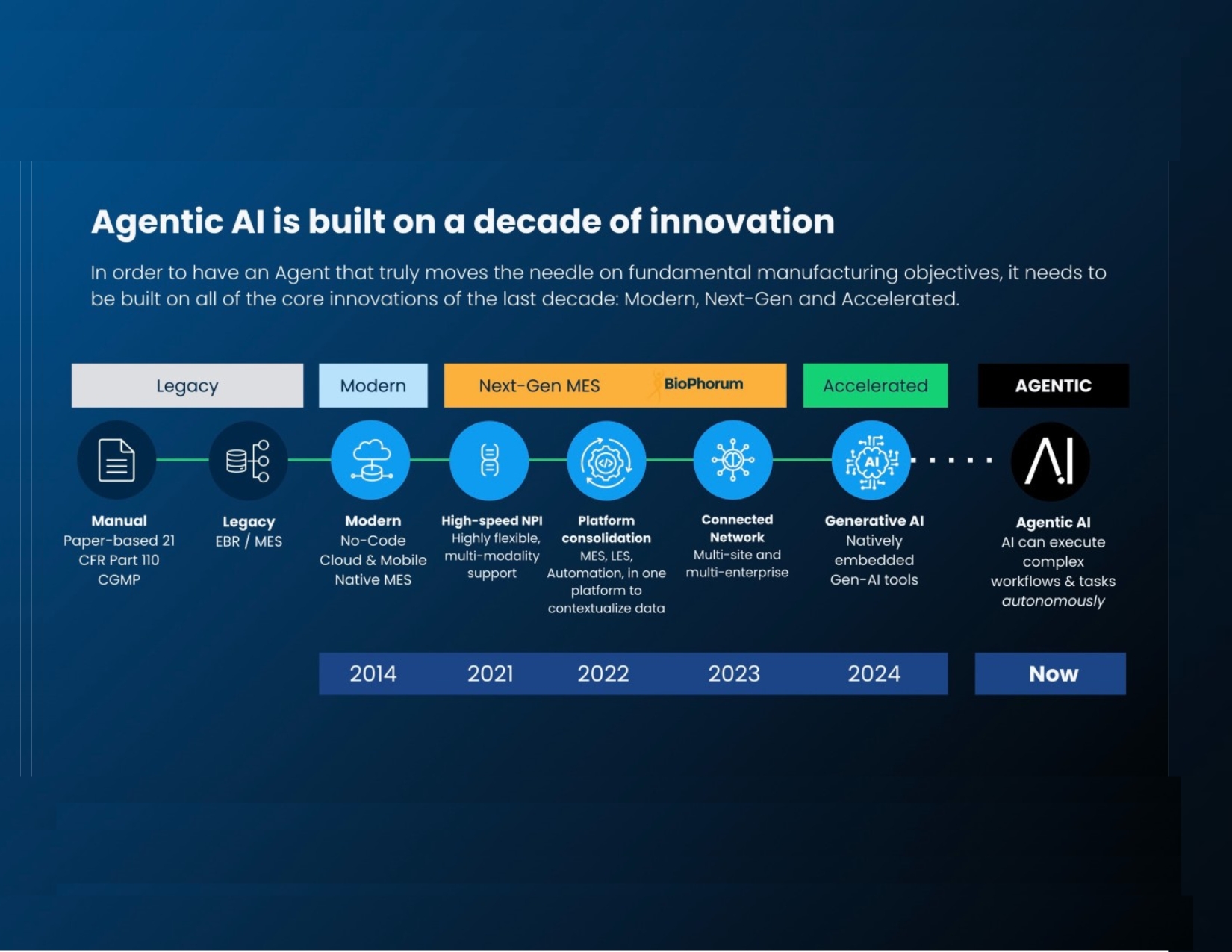

Apprentice started in 2014 with cloud-native training, and shook the market in 2020 with its GXP-focused Tempo MES being no-code, cloud-native, and available on mobile. Pharmaceutical, biotech, and vaccine companies started to adopt it with good results. These customers pushed for a broader footprint, including the lab execution (LES) and automation elements. Apprentice also added multi-site and multi-enterprise capable versions to serve its major pharma customers. Now AI is the news, and Apprentice has it, with additions that support all of the functionality and users in new, intuitive ways.

GenAI

Last year, the product gained generative AI capabilities. In Ask Apprentice, operators can ask questions about their tasks and get guidance on the spot. Supervisors can also see status and get production updates from this portion of the software. This is classic copilot capability for Tempo.

Other GenAI capabilities include a procedure author that can start with a prompt, an existing PDF procedure document, or the procedure from an MES and uses natural language for editing. It could also recommend procedures that the user could accept or reject. The AI Run Simulate capability could simulate and test procedures to ensure they behave as expected before deploying them to the operation.

Agentic AI

Apprentice is adding agents for authoring, quality, and a limited release for process in the September release. These take GenAI capabilities to the next level, with autonomous agents to execute tasks that still have a human in the loop. They have chain-of-thought reasoning and test their work. Authoring, for example, will check itself, quality will focus on things such as review by exception and batching for bulk approval. There is also a second agent checking the work and recommending edits to the procedures. These agents can test what executed values of a recipe would be using that procedure, and can iterate until satisfied with the output. The end-of-2025 release will include additional agents for scheduling and continuous improvement. All five agents were in beta testing when we met with them in August.

These agents are built on top of everything already in the Tempo system, which our research shows is what manufacturers want. The vision Apprentice has is that instead of scaling out teams with people, their customers will use these agents for tasks no one wants to do or that are time-consuming. The agents are intended to free the people for deep thinking tasks. In this way, the company believes they will make it easier to see the financial payback of MES by increasing throughput and decreasing the cost of goods sold (COGS).

Privacy, Guardrails, and Validation

Privacy: In the regulated environments Apprentice serves, questions abound. We asked about privacy and protecting the customers’ IP in these agents. Apprentice does not train the agents on customers’ data, but rather on internally generated golden run data sets.

Guardrails: Customers are in control of what agents can do. They can set per-agent parameters either globally or for each process. They also decide who can use which agentic and GenAI capabilities. This goes beyond existing Tempo roles and access controls.

Validation: Apprentice has, for years, followed FDA guidance for risk-based computer software assurance (CSA) validation, including documenting the validation. This reduces or eliminates the need for customers to do additional validation. With the agents, they are ensuring explainable decisioning, implementing data and concept drift, and stressing input conditions to see output accuracy, among other things. Apprentice product management and quality team members participate in the Biophorum AI validation work stream and the ISPE AI Guidance steering Committee to ensure they help drive and are up to date with the latest practices.

Customer Experiences

Apprentice manages over 7000 runs and 2000 exception approvals per month. Its customers have shared their successes at events such as Pharma MES USA.

Moderna used Tempo for a global facility expansion to improve preparation for a pandemic. Its greenfield plant went live in under a year, with 28 procedures created digitally in five months. The system is integrated with SAP and AVEVA OSI PI and operates as a fully validated GMP manufacturing facility.

A biologics CDMO used Tempo to digitize their labs and manufacturing operations. Batch records were a focus, and they did it without IT overhead or MES consultants. They had six sites go from kickoff to go-live in nine months. Their iterative approach achieved review by exception.

Looking Ahead

Apprentice expects to see enormous value for customers as the agents come online in full version releases later this year. It also has long lists of improvements in functionality, integration, analytics, and reporting or communications. Thank you, Emilee Cook and Justin Foreman, for explaining the product and company progress, and Kristen Kucks for setting up the briefing for Rick Franzosa and Julie Fraser. We look forward to our next update!