We’ve been excited to get briefed by Makersite over the last two years, and we’ve been impressed. Now, we’re happy to share what we’ve learned. They’re a small company that has big customers, and they’re helping those companies make significant gains on compliance, cost, sustainability, and supply chain risk. Given the impact of today’s global political and economic disruption on manufacturers, these improvements are crucial to success.

Product Lifecycle Intelligence

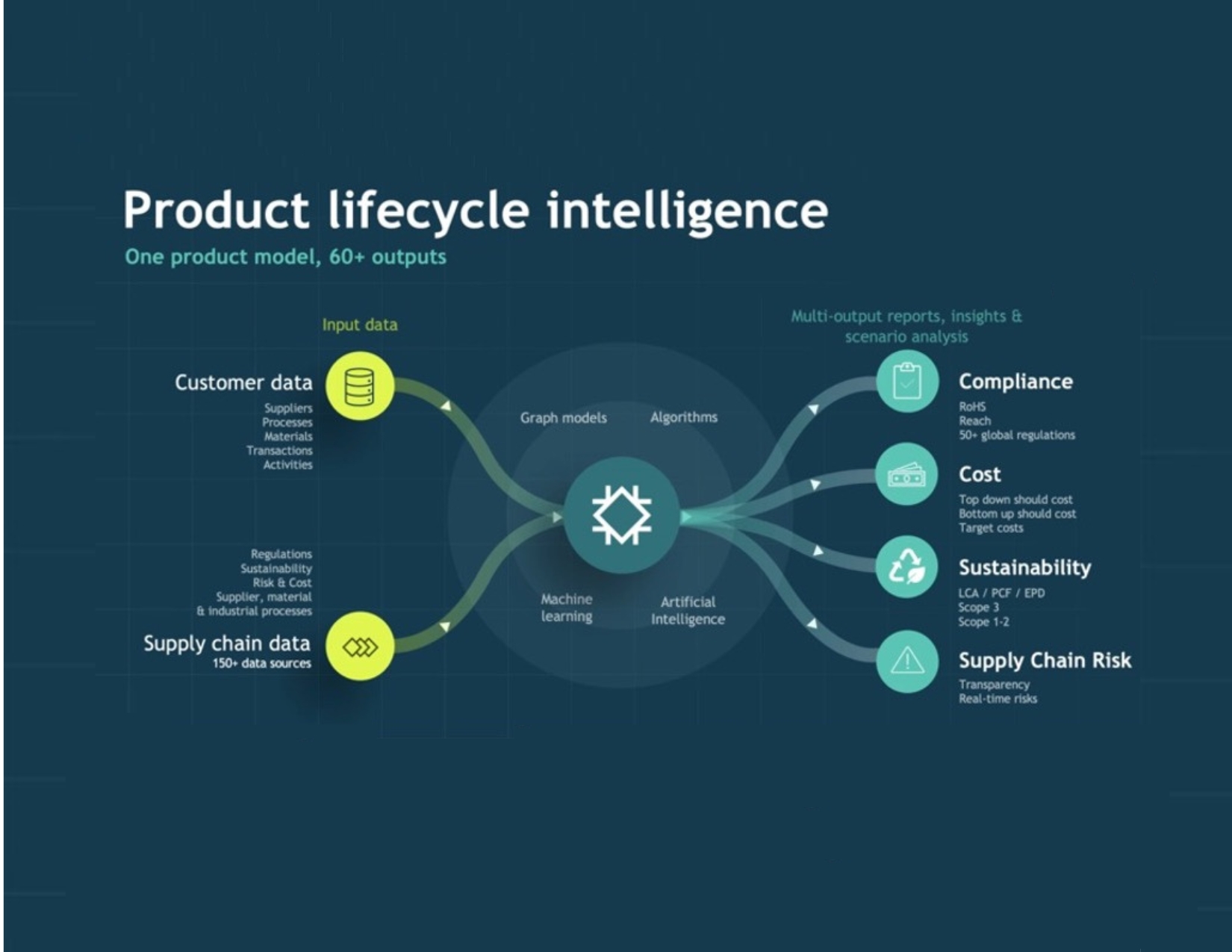

Makersite is addressing the dirty little secret about sustainable design and DFX in general. Engineers simply don’t know the impact of their decisions on factors like carbon footprint. If manufacturers analyze the impacts after the fact, it’s often too late to impact their design decisions. Makersite plans to change this paradigm by providing engineers with trusted data in the context of their product digital twin during design. If engineers have the right information, they can make better decisions to improve the impacts of their decisions and speed up product development by preventing design rework to meet cost, compliance, sourcing, or sustainability issues. Further, having the right information – what Makersite calls “Product Lifecycle Intelligence” – speeds up time to market by automating product documentation like LCAs (lifecycle assessments), product compliance, and company Scope 3 reporting, among other use cases.

Makersite believes that delivering Product Lifecycle Intelligence will help manufacturers source smarter, design greener, collaborate faster, and build more resilient supply chains. We respect their approach, which addresses sustainability in the broader context of product profitability.

Putting Product Lifecycle Intelligence into Practice

Our recent executive survey shows that manufacturers are facing increased calls for product transparency, for example, through product passports. It also shows that current economic conditions demand effective cost management and that trade wars and tariffs are making already challenging supply chains riskier. Makersite’s timing to offer Product Lifecycle Intelligence couldn’t be better.

Designing products like high tech electronics, which have complex supply chains, demands design tradeoffs that must be optimized early in design. Makersite’s Product Lifecycle Intelligence SaaS platform is based on a digital twin data model created from engineering BOMs. These data models, graph models that customers can refine, serve as both a visual representation of the product and the backbone on which to make LCA decisions.

From there, Makersite offers algorithms to help manufacturers map their digital twins to relevant data from a wide variety of sources. While they can use APIs to pull information from customers’ systems, such as ERP, PLM, or CAD, they also provide their own rich dataset. Makersite is not just an integration and calculation engine. They provide their own “decision-ready” data, including deep-tier supply chain information. They claim to provide the “world’s largest supply chain database” with over 150 external and verified databases.

Mapping this information to the digital twin creates the intelligence needed to make the right decisions and do so on a timely basis. We were assured that the data can be trusted because it is not a black box. Makersite offers a confidence score on their data and explained that transparency remains a cornerstone of Makersite’s approach. The platform allows customers to trace data sources, understand how the data impacts the modeling, and explore alternative options.

LCA Meets AI

Without diving too deeply into the technology, it’s important to understand the role artificial intelligence (AI) and machine learning (ML) play in Makersite’s ability to create a contextually rich digital thread mapping. Makersite refers to their platform capabilities as “AI powered Product Lifecycle Intelligence.” AI is a natural fit to map data from a variety of sources and formats into something meaningful. Makersite explained that their automation and AI capabilities ensure the most accurate and granular mapping for supply chain models, while continuously learning from user-driven changes to validate and refine the product models and reflecting those updates in future runs.

Customers

We mentioned that Makersite has an impressive customer list, with many in consumer electronics. They also shared that they have success in the construction and chemicals industries. But they are applicable elsewhere, as well. Some notable customers they list on their website include Barco, Schaeffler, Cummings, 3M, and Lenovo. One customer, Microsoft, jointly shared a case study with Makersite. The results were impressive, including a 30% reduction in carbon footprint in design for the Surface Pro, in addition to making it more energy efficient in use. They also leveraged digital twins to source better materials. They then applied this approach to other Microsoft consumer products and their data centers.

Our Take

Makersite is serving a valuable role at a time when manufacturers need it. Their ability to model product digital twins from customer data and enrich it with additional information from customer systems, third-party data, and Makersite’s own dataset makes it compelling. Their use of AI to contextually map data is a unique approach and solves quite a few of the challenges companies have faced in initiatives like LCA in the past. We’re excited to see their further success and adoption in the industry.

Thank You

Thanks to Nicolás Artímez Wetz for the briefings and Vaqais Hussain for initiating the conversations.