Can you gain operational insights from AI without data scientists or programming? Can you do it at scale in a highly automated environment? TwinThread would say you can. Working to solve this challenge, the company is growing rapidly deploying its SaaS Industrial Digital Twin AI Platform. In November, they were 322 on the Deloitte Fast 500 Technology company list.

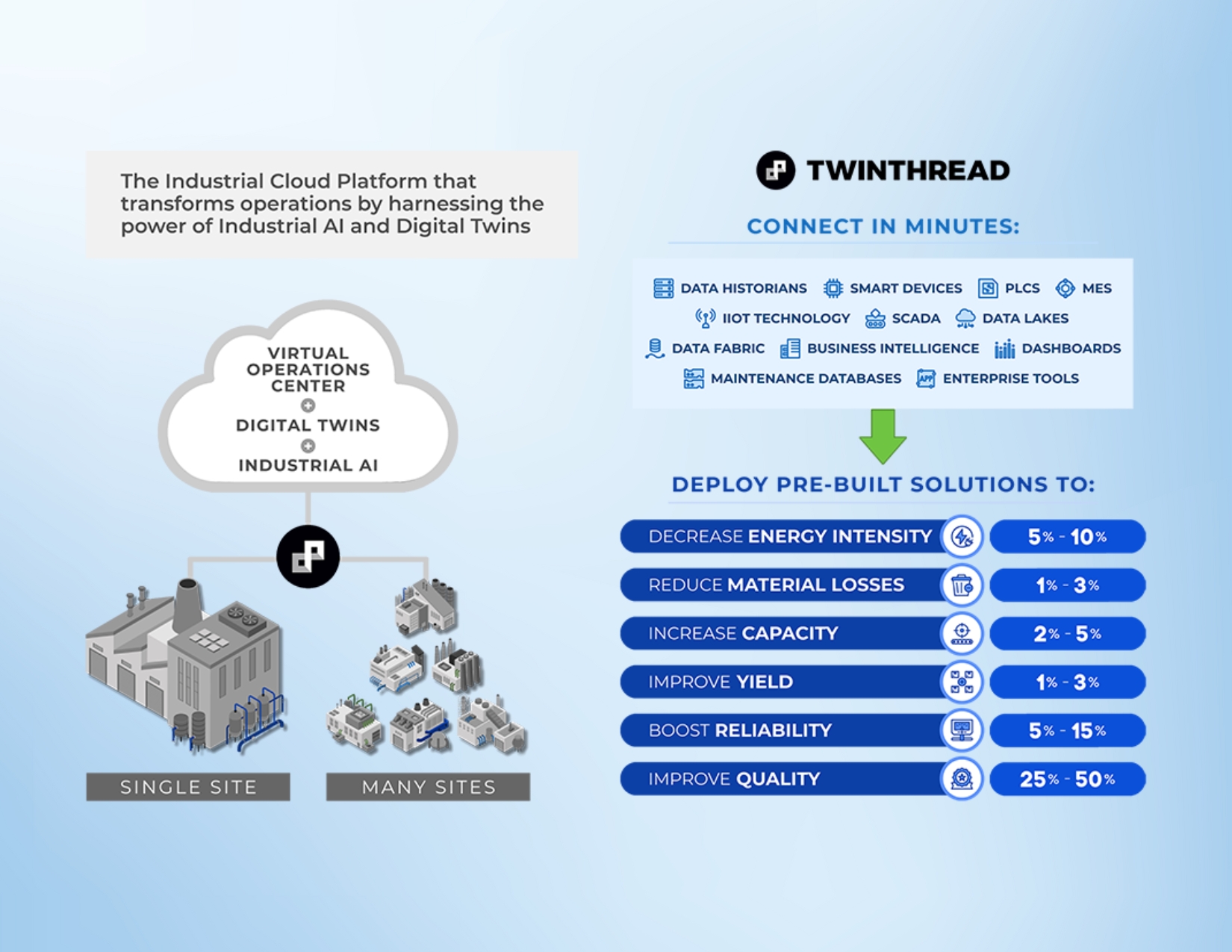

TwinThread offers a cloud-native SaaS AI platform based on a digital twin with pre-built applications. They claim these solutions connect rapidly to existing systems, often deliver insights within hours, and solve complex industrial problems within days. The improvement-focused offerings are designed for mid-size and large companies in two primary markets:

- process and hybrid manufacturing to improve production outcomes

- machine builders to monitor their equipment in the field.

Substantial Results

One pet food maker rolling out TwinThread globally reports that they are saving $1.3M per year based on a subscription cost of $108K/year by using the predictive quality module. Across five plants and 18 lines, the system recommends real-time changes in processes and ingredients. This enables the company to optimize the parameters that matter most to the quality of their products: moisture, fat, protein, and product density.

With a combination of current, in-context data and applications that support the most common issues facing these industries, the TwinThread customer base is growing. Some are rolling out and gaining ROI on problems they failed to address previously. Value can expand over time as the platform gains more data and customers add more use cases or applications, or moves to greater autonomy. The pet food company reports never again having a bad batch, and the Cpk or process quality index improved over 40%.

Virtual Operations Center

The founding vision is to offer a virtual operations center where people can monitor plants and lines worldwide. This enables customer companies to more fully leverage the scarce employees who have the most domain expertise. The pet food company achieved those results in the face of employee attrition, with operator experience dropping from 10 to 2 years.

As data comes in, it can support the continuous improvement cycle by monitoring, alerting to issues, recommending improvements, learning through machine learning, and solving problems. This virtual operations center can be a foundation for improving operational and business performance.

Growing Capabilities and Ecosystem

TwinThread was founded in 2017 to provide industrial data management and prebuilt solutions at the IT/OT intersection. They recently added the Enterprise Data Factory to deliver pre-curated big data sets for industrial or enterprise business intelligence. At this stage, the company has over a million process or operational digital twins in customer use. Each of those includes actual and historical plant data, not just a simulation.

Partnerships have been a hallmark of TwinThread’s strategy from its early days. The company now has over 400 channel partners, including GE and AVEVA. It has Transformation, System Integrator, Technology, and OEM partners. The latest announcement was with AWS for native integration to IoT SiteWise.

SaaS AI Platform

The Predictive Operations Platform is a SaaS Industrial Digital Twin AI Platform. It includes out-of-the-box connectors and agents or dockerized containers at the edge. It feeds that diverse data into a process digital twin at the core. On top of the twin, a thread engine layers additional context and visualization. The platform also includes logic streaming, the ability to build out if-then-else logic for event detection, and capabilities for data curation, cleaning, and orchestration of behaviors. The behaviors can be fully automated or deliver prompts for people.

Focused Applications

TwinThread sees that instability and variability are underlying problems for process and hybrid industries. As long-running processes often have inertia, optimizing them can be a challenge. So, the system focuses on helping companies identify the drivers of instability and move to a more consistent approach to running their production. The applications focus on both process-centric use cases and asset-centric use cases.

System Users

The users are operators, engineers, and digital teams. TwinThread calls the engineers and operations subject matter experts developers since they use TwinThread to mine data and solve problems without writing code. The operators are the customers of what they develop. Data scientists also use the platform to feed their tools, such as Jupyter Notebooks, to configure machine learning and data science workflows.

Deployment Approach

Enterprise-scale customers have typically failed more than once to scale with other approaches. Normally, TwinThread starts by defining success criteria for a three-month pilot on a single line and a few use cases. Their preferred approach is to mentor a process engineer to create the pilot themselves. By then, the customer understands how quickly and easily they can model their process in the digital twin and are typically in production and seeing benefits.

TwinThread’s comprehensive approach addresses people issues by enabling the process engineers to develop what they need and then having expert operations staff available in the virtual operations center to support the less experienced team members. The system maps processes in the digital twins, delivering inherent context to the data.

Deeply Experienced Team

TwinThread was founded by three successful pioneers in process and hybrid production software. They met at Mountain Systems, which became GE’s Proficy MES and Historian. The co-founders are Erik Udstuen, the CEO, Tom Nettell, the CTO (those two co-founded Mountain Systems in 1996), and Andrew Waycott, the President. The team includes long-time industry mavens Brandon Ekberg, one of the first MES experts, running Product, and Sheila Kester, ex-GE, Emerson, and Intellution, running operations. Jason Dietrich, as CRO, is a recent hire with deep experience in manufacturing software.

Thank You

Thank you, Sheila Kester, for setting up the briefing. Thanks also to Andrew Waycott, Marc Albu, Elise Loffredo, Jason Dietrich, and Brandon Ekberg for your time and insights in the briefing. We look forward to following TwinThread’s progress and continued profitable growth for the company and its customers.