Semiconductor makers must evolve and innovate, so how can MES keep delivering value? Specialty chips can be great niches, but they don’t necessarily improve linearly or predictably. So, semiconductor companies must become more effective innovators rather than only seeking stability or increased product processing speed. Changing products, processes, and customers can boost win rates. No matter what, research and development (R&D) is a crucial foundation for business success.

Semiconductor makers must evolve and innovate, so how can MES keep delivering value? Specialty chips can be great niches, but they don’t necessarily improve linearly or predictably. So, semiconductor companies must become more effective innovators rather than only seeking stability or increased product processing speed. Changing products, processes, and customers can boost win rates. No matter what, research and development (R&D) is a crucial foundation for business success.

Yet historically, innovation, changes, and R&D created significant challenges for legacy MES. As a result, these older systems have lost value over time. Semiconductor companies need MES that is reliable and flexible to keep up with innovation and evolving business and production processes.

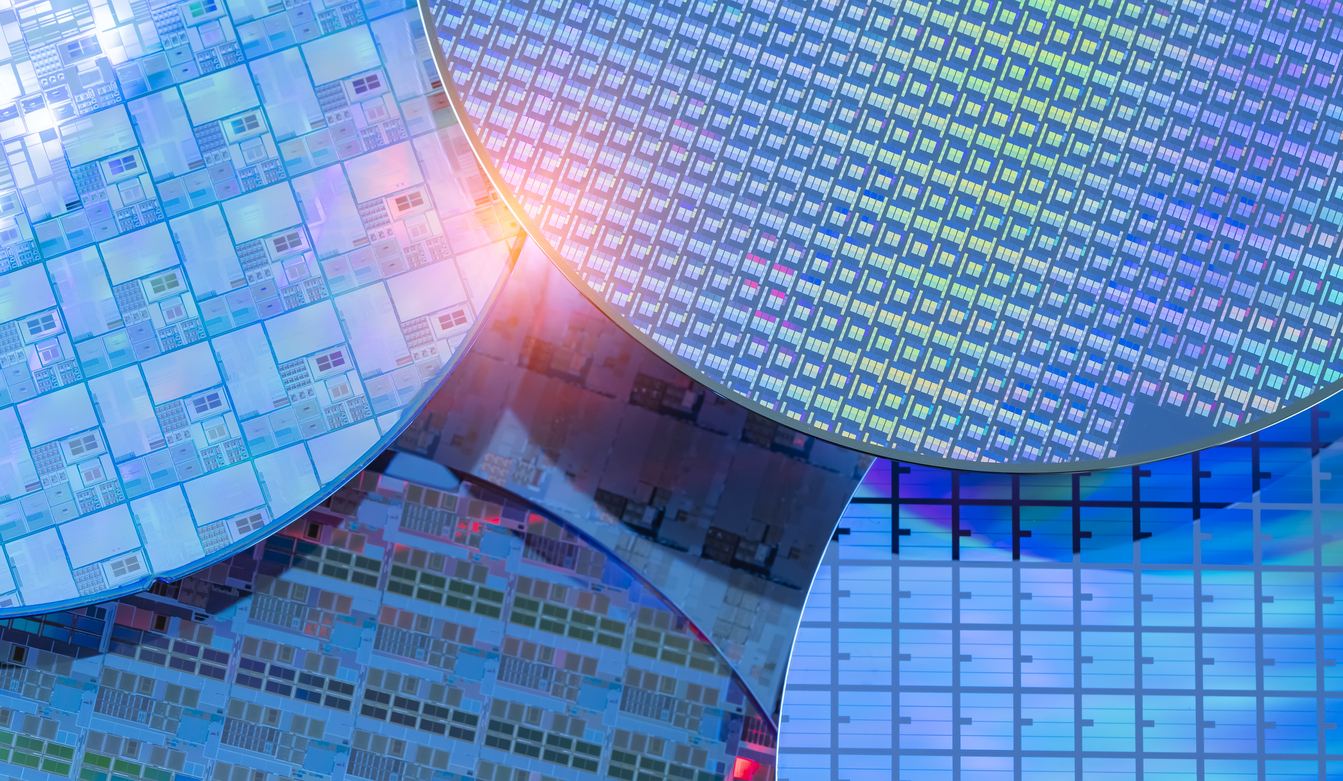

Meeting new applications that build on the company’s current capabilities is a winning strategy. Specialty chips often work where virtual meets real. The intersection of virtual and real is also where MES models and capabilities meet actual fabrication, assembly, and test of chips.

In the face of constant innovation, the MES must be able to process multiple experiments at the same time as standard runs. The MES should be able to support fabs in running experimental lots with little to no disruption to commercial production. The MES ideally fully records and reports all the runs, small, large, or one-off experiments.

For reliability at the same time as flexibility, it’s ideal to have an MES that includes not only dispatching of special and commercial lots, but also maintenance, quality, materials, and more. The value comes from support for all aspects of change and innovation.

Fortunately, there are semiconductor MES available that have all of that and support greater agility with less manual effort than ever before. These modern systems enable semiconductor companies to set and meet their goals for evolving and innovating into new market opportunities. Choosing the right semiconductor MES to evolve and innovate is crucial.

Read this third in a blog series about semiconductor MES issues by Julie Fraser for a deeper look into what you might need and why. Thank you to Eyelit for supporting our efforts to educate the market to the business value of technology.

For related content, please read the previous senmconductor blog posts by Julie Fraser on Eyelit, including Redefining Semiconductor MES and the Semiconductor Risk Conundrum.