Reinventing MES/MOM and Operations

We’ve followed Tulip since the early days and were excited to catch up and see what they have accomplished over the past year. From their inception, Tulip Interfaces deliberately set themselves apart from existing industry acronyms like MES (Manufacturing Execution Systems) and MOM (Manufacturing Operations Management). This decision offered advantages and challenges, as many manufacturers seek solutions based on a clearly defined TLA (Three Letter Acronym). Instead, Tulip introduced itself as a Frontline Operations Platform. Early adopters of the solution/toolkit were drawn to Tulip’s platform for its intuitive application development and the potential for reusability—well before “composable enterprise” became an industry buzz phrase.

Critics and skeptics initially raised concerns about the absence of a unified data model, weak configuration management, minimal revision control, governance, and limited security. Over time, however, Tulip addressed these shortcomings. The platform matured, the library of available applications expanded, and critical features were refined.

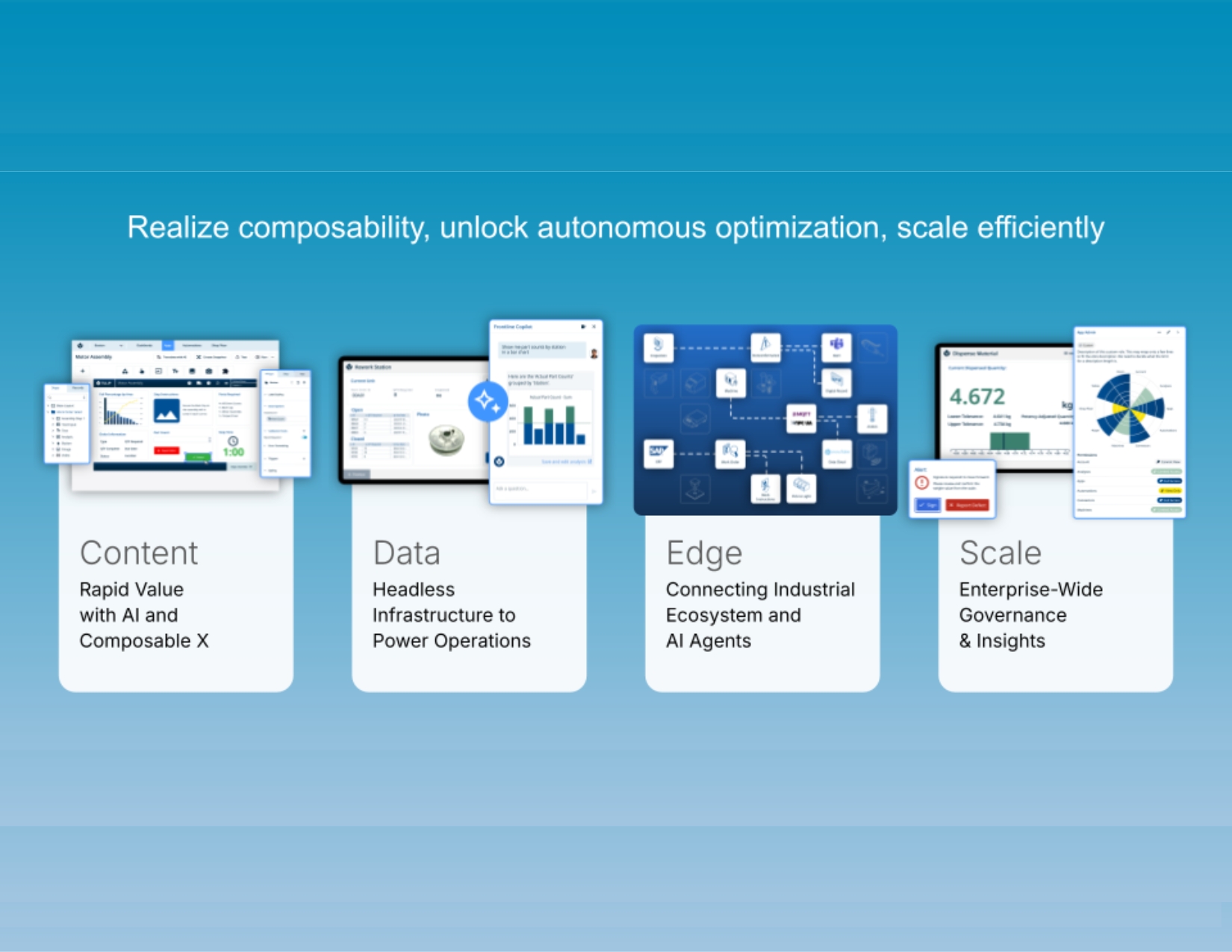

Tulip’s reach grew from its roots in discrete manufacturing to include life sciences—encompassing pharmaceuticals, biotech, and medical devices—and now extends to aerospace and defense. Tulip has continued innovating in content and data management, edge and enterprise connectivity, and security and governance throughout this evolution.

Tulip is well-positioned as a data analytics and insights platform developer designed to transform factories and manage global operations digitally. Our research shows that manufacturers investing in Analytics and AI are gaining substantial benefits (see Making Manufacturing Analytics and AI Matter). The benefits matter, as they are in the areas that match their objectives: cost, efficiency/productivity, quality, and error-proofing, most commonly.

Keys to Success – Composability and Connections

The strength of the Tulip platform has always been the ability to start with predefined functions and compose a solution that can be easily modified and/or extended to meet additional needs. To accelerate customers’ abilities to create and extend these solutions, Tulip has provided a library of more than 170 predefined apps and more than 40 predefined app suites. If you are in an industry currently supported by Tulip, you will likely not be starting from scratch to build a solution for your production floor. Suppose your concern is the ability to connect to devices. In that case, Tulip supports the expected protocols for automated equipment (OPC UA, MQTT, Snowflake (UNS), etc.) and web-enabled no-code HMIs for Rockwell Automation, Inductive Automation, DMG Mori, and others. In addition, they have edge drivers for the more mundane devices that most MES vendors do not provide, label printers, scanners, torque tools, pH meters, thermocouples, cameras, scales – over two dozen device types from over thirty vendors. Coupled with drag-and-drop integration connections to ERP and SCM systems, they have created a composition platform that can be used to develop applications and connections for a production-ready system.

Keys to Success – Automations and AI

In 2024, Tulip added a workflow engine to the application creation suite. This capability is called “Automations”, as it is the ability to define workflows and automate them. Like other Tulip capabilities, their library has predefined automations for everyday tasks (more than fifteen at this writing) such as inventory update, part counts, Andon alerting, and production status. As the MES vendor community evaluates the uses of GenAI and LLMs in production, Tulip has built MCP server, their official implementation of the Model Context Protocol for the Tulip platform and is using existing connections and automations as a bridge to Agentic AI. The library already includes two: AI Automation – Defect Characterization and AI Automation – Defect Summarization.

While some skeptics felt it took Tulip way too long to add workflow capabilities, the Automations allowed them to leapfrog some of their competition, past traditional workflow to AI Agents.

Keys to Success – Domain Expertise and Scalability

To support Tulip’s continued growth across industries, it is essential to develop internal expertise in target markets and provide customers with tools and training for scaling from DIY pilots to enterprise production. Tulip is adapting functionality from apps designed for other industries to support new ones, hiring domain experts for those new target industries. This is a valid approach, admittedly time-consuming, especially where it relates to the support of domain-specific rules and regulations from CFR 21 Part 11 to FedRAMP.

The first part of full enterprise support has been achieved by building out their implementation service provider network, currently 90+ implementation partners in 25+ countries, which represents 50% growth year-over-year. However, expertise is something that is acquired over time, as other vendors have discovered. The growth rate of signing new partners does not translate to overnight success.

Future Directions

Some of the areas discussed by Tulip include:

- Their goal is to demonstrate equivalency for FedRAMP, or the Federal Risk and Authorization Management Program, in 2025. FedRAMP is a standardized security assessment and authorization approach for cloud service offerings used by U.S. federal agencies. It aims to provide a cost-effective, risk-based approach to adopting cloud services. FedRAMP ensures that cloud services meet a baseline level of security requirements before government agencies can use them.

- Development of functionality for additional enterprise content sharing across sites and divisions that use Tulip as their operations platform.

- Additional functions and UI components for composable app creation.

- Extending the capability demonstrated at Hanover Messe to create standard operating procedures (SOPs) from a PDF file to app generation from a PDF.

- Improvements in the creation and management of the Tulip ecosystem via a Tulip SDK and a device ecosystem

Thank you to Madilynn Castillo and Natan Linder for the insightful briefing.