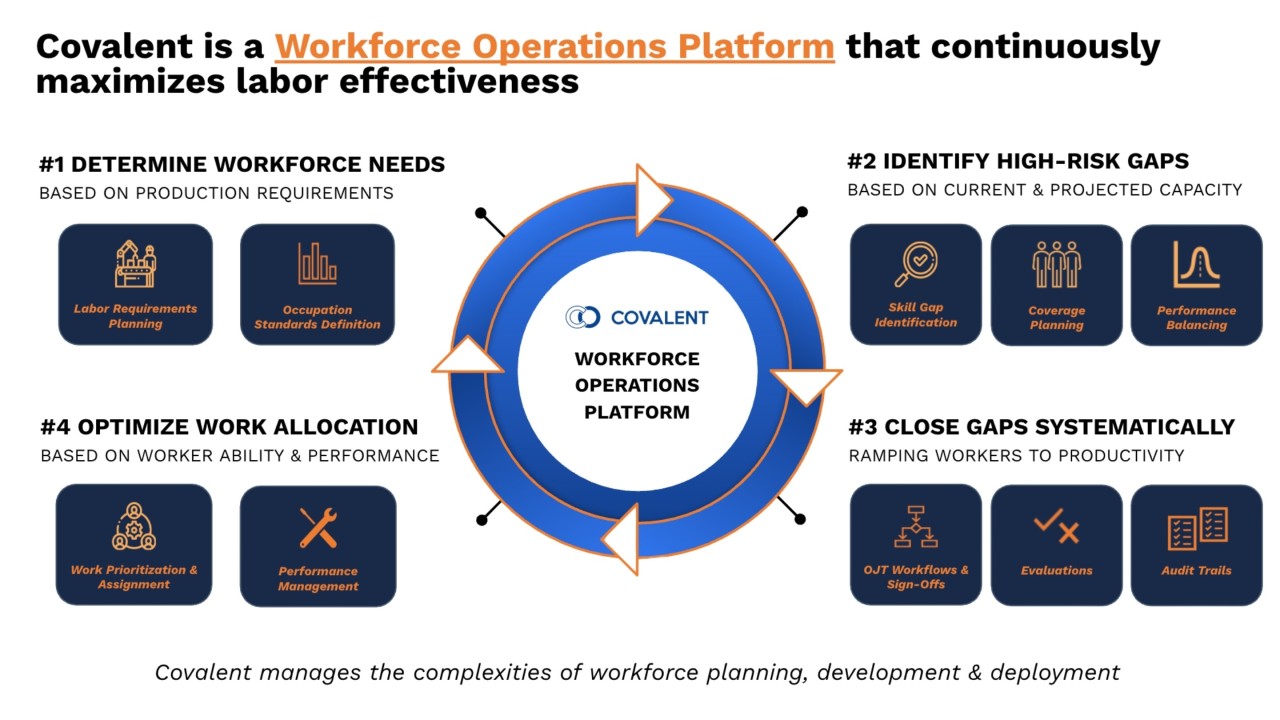

Can manufacturers maximize plant human resources as effectively as inventory and equipment? Covalent would say yes. That is what their workforce operations platform is designed to do: continuously maximize labor effectiveness. They continue to build out in multiple directions: functionally, beyond tracking training and job experience to creating an interactive skills matrix, optimizing work allocation, and last-mile line staffing. They have also gained new customers beyond A&D and automotive in chemicals and CPG.

Workforce Operations Platform

Covalent’s main users are manufacturing, engineering, and quality leaders. They need to answer questions such as: How many people do we require? What quantity and quality of skills do we need for the work we have this week, today, or on this shift? How do we train up our people to fill any gaps? Is all of this easily auditable?

To answer these labor-related questions, Covalent’s Workforce Operations Platform creates a profile for every employee with details of their skills, knowledge, and experience. Covalent’s platform is based on the AWS Cloud, which brings benefits in security, compliance, and infrastructure. Both the AWS and Covalent platforms continue to improve and deepen over time.

On this SaaS platform sit role-based solutions, typically aimed at manufacturing, engineering, and quality leaders. Imagine having all this information about each employee in the plant to plan coverage for the week, day, or shift. This continuous employee tracking also enables remediation when quality trends show problems relating to how someone performed a task at a particular work area.

Covalent has many built-in objects often found in MES, such as assets, work centers, tasks, and jobs, to understand an employee’s eligibility to perform a piece of work. Being able to gauge whether an employee has the skills and certifications needed to buy off and start a task is also hugely beneficial for both manufacturing and quality leaders.

Integration and Building on LMS, MES

Integration with the manufacturer’s learning management system (LMS) is just one element of training. Covalent can also deliver content, evaluations, training tasks, and digital sign-offs. It also integrates with time and attendance (T&A) and MES to enable touch and task performance tracking for employees as they perform the work. Beyond that, the newest functionality also interacts with advanced production planning and scheduling (APS) to deepen the ability to ensure scheduled work has the staffing in place to be executed efficiently and compliantly.

Covalent is already integrated with SAP, Siemens Opcenter, and iBase-t Solumina MES. It is also integrated with LMSs such as Workday Learning, SAP SuccessFactors, and Cornerstone. There are some overlaps with LMSs, but Covalent’s clear OTJ extensions seem to keep customers happy.

Interactive Skills Matrix

One of the newer capabilities is an interactive skills matrix. The benefit of interactivity is that users don’t need to jump pages or go to email. They liken it to Google Maps; you can drill in and assign training or drill to see each person’s training. The matrix includes parent-child relationships and digital forms to complete for training or renewal logic.

The system can also layer on alerts. So if, for example, a certification has an expiration date, the system can alert the supervisor that a person will need to take refresher training to continue all the work they’ve been doing.

Intelligent Work Allocation

One of Covalent’s newest capabilities is Intelligent Work Allocation (IWA), which improves production accuracy even in the face of workforce shortages. A smart job assignment board helps ensure the system sees job touch data that enriches the employee profiles. With this, work order data and job progress come together with who is on shift.

A machine learning (ML) algorithm creates a suggested or optimized build plan with people allocated to it based on the needs for the day. The system’s logic can account for jobs where multiple people are needed for a step, or one person follows the product or serialized assembly through many steps. The supervisor reviews the plan and has the opportunity to override it. Supervisors can also review the shift performance at the end.

One large A&D customer already has this capability in production. Covalent’s team is also working to perfect the capabilities for automotive within-shift ergonomics rotations. Remember, Covalent started out in training, so creating a shadowing shift for someone to learn is part of what this can do, too.

Origins in the Future of Work

Covalent started in 2016 while the founders were in graduate school in the Harvard Future of Work program. The focus was to play a broker during the shortage of skilled manufacturing workers. Initially, it was focused on replacing paper-based forms and Excel for structured apprenticeships at defense contractors and European companies. They evolved into on-the-job (OTJ) training for some of the same very complex discrete manufacturers. Today, customers have pulled the company well beyond the training management roots.

Benefits and What’s Next

Covalent already has over 50,000 users on its platform. Many work at a handful of A&D companies that have deployed the platform across their enterprise. So far, the company appears to be doing a great job of balancing the needs of current customers. They report

- 5% increase in line productivity

- 5X increase in bench strength without adding headcount

- 12X ROI with over $10M in savings from an enterprise rollout

- 65% reduction in training time

- 92% of manual administration tasks digitized, and 40% of those tasks automated

- Passed over 1000 audits

Word-of-mouth is starting to help Covalent sell in the A&D market. We expect customers across industry segments to continue expanding the solution set in this innovative platform. Thank you, Matt Delaney, for briefing Rick Franzosa and Julie Fraser on your vision and progress in the market.