Tech-Clarity Insight: The Business Value of Product Data Management: Achieving Rapid and Extendable Benefits explains how manufacturers use PDM to control their product data, improve their ability to find information, and better share knowledge with other departments. The report shares the experiences of three manufacturers that took a more “out of the box” approach to reach these benefits quickly.

Tech-Clarity Insight: The Business Value of Product Data Management: Achieving Rapid and Extendable Benefits explains how manufacturers use PDM to control their product data, improve their ability to find information, and better share knowledge with other departments. The report shares the experiences of three manufacturers that took a more “out of the box” approach to reach these benefits quickly.

Note: This report has been updated, please see the current version of the report here.

Table of Contents

- Executive Overview

- The Business Value of PDM – Controlling Product Data

- The Business Value of PDM – Making Product Data Accessible

- The Business Value of PDM – Sharing Product Data

- Achieving Value Quickly (and Painlessly)

- Getting Started

- Taking Advantage of (and Extending) the Benefits

- Conclusion

- Recommendations

- About the Author

Executive Overview

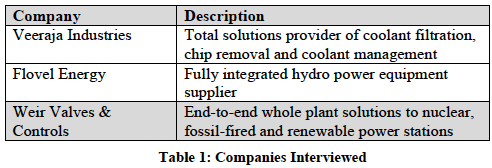

Manufacturers today are facing challenging markets and uncertain economies. To survive these conditions they are trying to improve the speed of product development despite reduced headcount and budgets. One positive note is that many manufacturers are gaining significant value by implementing product data management (PDM) solutions. Tech-Clarity interviewed several small to midsize manufacturers (Table 1) that implemented Teamcenter Express from Siemens PLM Solutions as their PDM system to understand their experiences. Each of these companies implemented PDM for different business reasons, although several common themes were repeated. These themes are consistent with previous research on the topic, and include:

- Control and secure product-related data

- Improve the ability to quickly find and reuse information

- Share product knowledge with other departments

Manufacturers turn to PDM in order to take control of their product information and get more value from it. These solutions help companies manage their data and make it accessible to their Engineering peers as well as downstream departments such as Manufacturing. As a result, PDM helps these companies achieve business benefits including increased efficiency, improved quality, reduced cost, and the ability to bring products to market much faster.

Discussions with these manufacturers reveal a lot about that their PDM implementations. For example, implementing the software without significant modifications helps companies achieve benefits more rapidly. Companies can accomplish this by using preconfigured, or “out of the box” PDM solutions. These solutions offer preconfigured settings and data such as roles, reports, attributes, and forms to allow manufacturers to get up to speed quickly. They also provide best practices embedded in preconfigured workflows so manufacturers don’t have to define processes from scratch where they currently have manual or outdated processes. This approach allows companies to get up to speed quickly and then grow from there to gain further benefits, providing engineers with the right tools to do their jobs efficiently.