A quick peek into some research on … the respective roles that ERP and PLM play in product innovation. This is not brand new research, but I believe it is just as relevant today as when I initially wrote this almost 5 years ago. Why? Not much has changed – with a couple of notable exceptions (SAP and Oracle). I find myself coming back to this topic on a regular basis, and I am starting to do some research in this area again so I thought I would bring this one back to the surface. It also offers some insight that might be helpful for a recent discussion on PLMTwine that touches on the importance of integrating PLM with ERP.

The Research

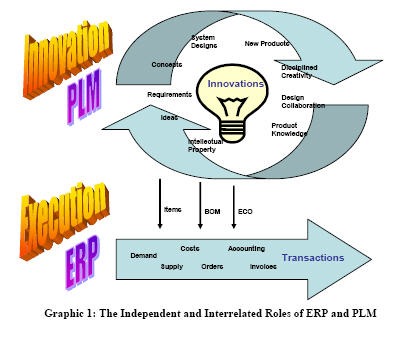

The research identified two clear and distinct sets of business processes that companies use to drive product

profitability. These two sets of processes include:

- The Innovation Cycle – characterized by rapid iteration

- The Execution Cycle – characterize by a more linear, repeatable process

These cycles are different, and require different solutions. PLM and ERP were developed – and have since evolved – to meet the needs of each of these cycles. Is there overlap? You bet. Processes like engineering change are consistent challenges to coordinate between these two meta-processes. But for most companies, there is

a clear hand-off point where a design is released to manufacturing (and external suppliers, for that matter)

where ERP takes over.

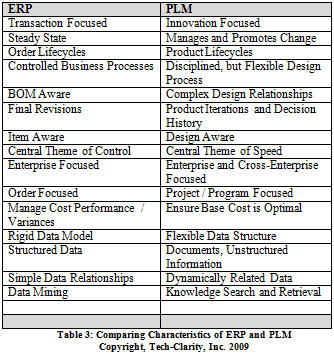

Below is a table extracted from the research that helps to show the differences between ERP and PLM. These differences are what make each the best solution for their respective set of processes – execution or innovation.

Updating the Viewpoint

So what would I change now that five years have passed? Not much. One other interesting fact from the research (and confirmed by a later benchmark I conducted at Aberdeen Group) is that most companies would really rather have one enterprise solution that covers all of their innovation and execution needs. Unfortunately, at the time none existed. I would love to say that five years later that had changed drastically, but it has not. What has changed? The desire for an integrated solution clearly has not changed, but:

- PLM vendors such as Dassault Systemes, PTC and in particular Siemens PLM have progressed their integration to ERP, focusing mainly on SAP due to it’s market prominence in ERP

- Oracle acquired Agile, giving them a PLM solution (two actually, including Prodika) that will be further integrated with Oracle ERP over time, but is also being sold into other ERP environments (again, including SAP)

- SAP has announced and is progressing on their own SAP PLM roadmap (Update: Look for a One to One on SAP PLM in the near future, we have just had a good conversation with the SAP PLM team about their progress)

Having said that, none of the above are clearly differentiated enough to serve as the “one integrated

answer” that many companies are looking for. So for now, the best solution is likely a hybrid of ERP, potentially some PLM from you ERP vendor, some best of breed PLM suite solutions, and some best of breed point PLM solutions. Sorry, I wish there were a cleaner answer than this.

So that was a quick peek into some recent research on the roles of ERP and PLM. I hope you found it interesting. Does the research reflect reality? Do you see it differently? Let us know what it looks like from your perspective.