Focused PPM Functionality

Based in Germany near the Swiss border and Boston, MA, eschbach has built software that works by staying close to local pharmaceuticals and chemicals companies. These companies run 24/7, and much of the critical process happens in tanks and enclosed spaces where people cannot see the process or easily interface with the automation. eschbach was founded to connect humans to each other and technology for safer, smarter, and stronger manufacturing.

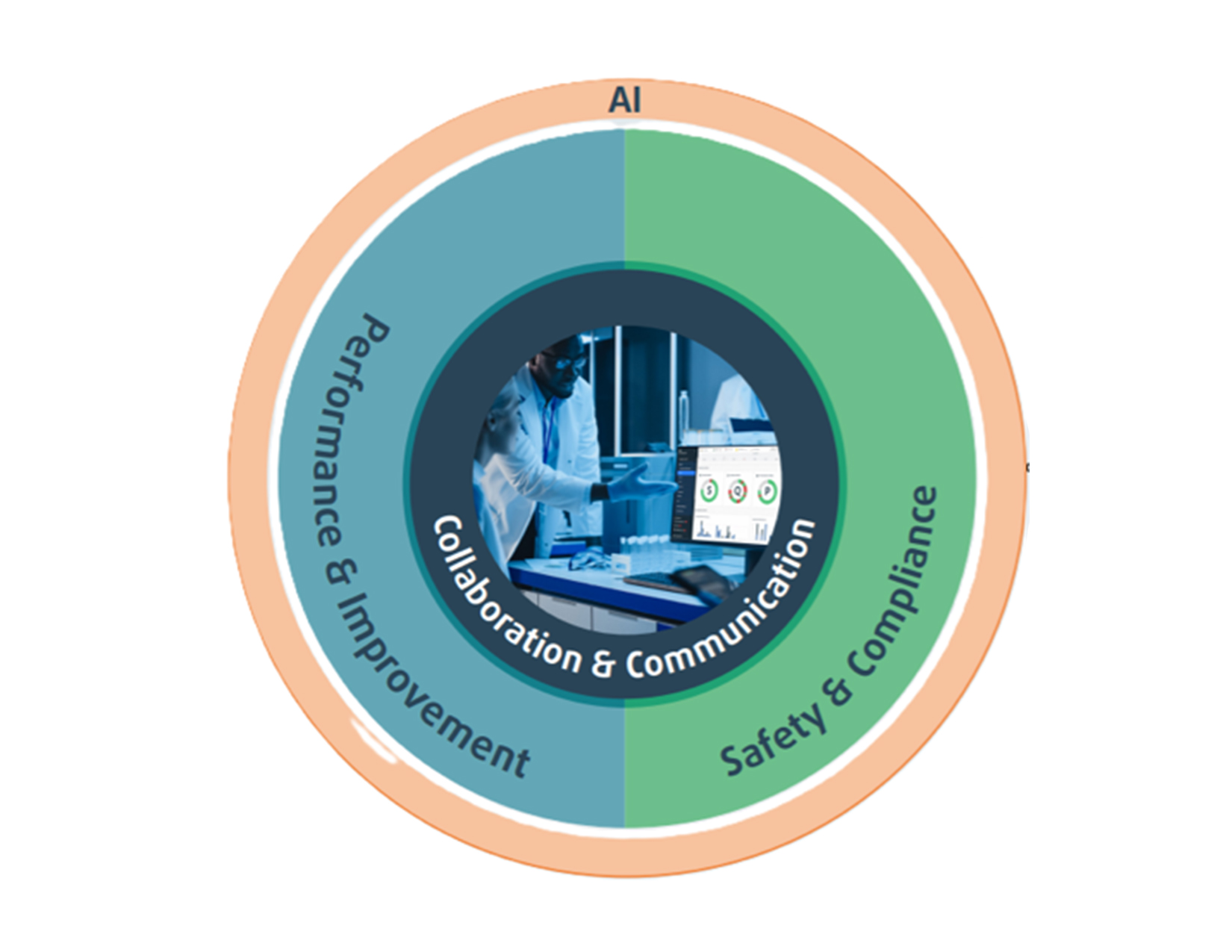

The eschbach Shiftconnector platform includes functionality for:

- plant operation and collaboration

- process and worker safety

- industrial and asset performance

It turns out that the shortage of skilled workers plays right into eschbach’s strengths. Communication and collaboration with current technology can make a workplace more attractive to shift workers and process engineers. Production meetings can happen on Shiftconnector, with some in the control room and others attending virtually.

Like other PPMs, Shiftconnector has connectors to the automation and equipment layers. Connectors to time-series data historians have been in place for years, as have ERP and Enterprise system connectors to SAP and IBM Maximo. Plant operators use Shiftconnector to see the data from all those other systems.

AI for Human-Technology Interaction

Realizing that 50% of plant incidents occur within 30 minutes of a shift change, that handoff was a crucial starting point for eschbach’s thinking and product roadmap. A few years ago, they realized that a specific language model to parse the shift logs of these chemical and pharmaceutical companies might do just that. Their AI R&D team worked with universities on German government grants for years to create specific language models for these industries’ production issues.

Shiftconnector now includes AI, which uses natural language processing, machine learning, and semantic search to go beyond traditional keyword search in process plant management. Shiftconnector AI structures data and isolates relevant information to provide solutions based on the search terms. The system currently includes 12 AI models specific to this domain. The machine learning approach also helps ensure the system acquires and documents tacit knowledge.

Market Success

Some giants in chemicals and pharmaceuticals are eschbach customers. For example, Air Liquide, Albemarle, BASF, Bayer, DSM-Firmenich, and Roche have posted case studies and testimonials about using Shiftconnector.

With European roots, eschbach has a US subsidiary in Boston and is present worldwide. Many customers have adopted Shiftconnector across all of their production facilities, resulting in strong global growth for eschbach.

Partner Credibility

eschbach has strategically supported the big tech companies, integrating Shiftconnector with their software and hardware solutions so that the operations staff could easily access them. Now, big software companies are partnering with and recommending eschbach to their chemicals and pharmaceuticals customers.

- Shiftconnector is in the SAP Store, and SAP refers chemical and pharma customers.

- AVEVA is a long-time partner that promotes Shiftconnector in conjunction with their software.

- Microsoft Azure is a technical partner, and their practice leads know eschbach.

These giant companies carry weight and can choose partners, so we feel these are strong endorsements of the Shiftconnector platform and eschbach’s approach. The Industry 5.0 focus on human-machine interaction could keep eschbach and its ecosystem of partners busy into the future.

Increasing Success

As a 20-year-old company, eschbach’s rapid growth is impressive. Thank you, Valerie Harding, for making the connection, and Andreas Eschbach, for taking the time to get us up to speed. Now that we’re connected, we look forward to collaborating and following the company’s progress. We will look for news that fuels more effective work in process plants.