Once you have machine monitoring, MES, and scheduling on a common plant data model, how can you improve the ability to automate and execute the work? MachineMetrics is doing that by adding Max AI. While the company started in machine performance monitoring, this year it has expanded to focus on plant performance and frontline worker performance (See previous insight). This comprehensive plant data set, which can also encompass multiple plants, serves as the foundation for Max AI.

Agentic Execution

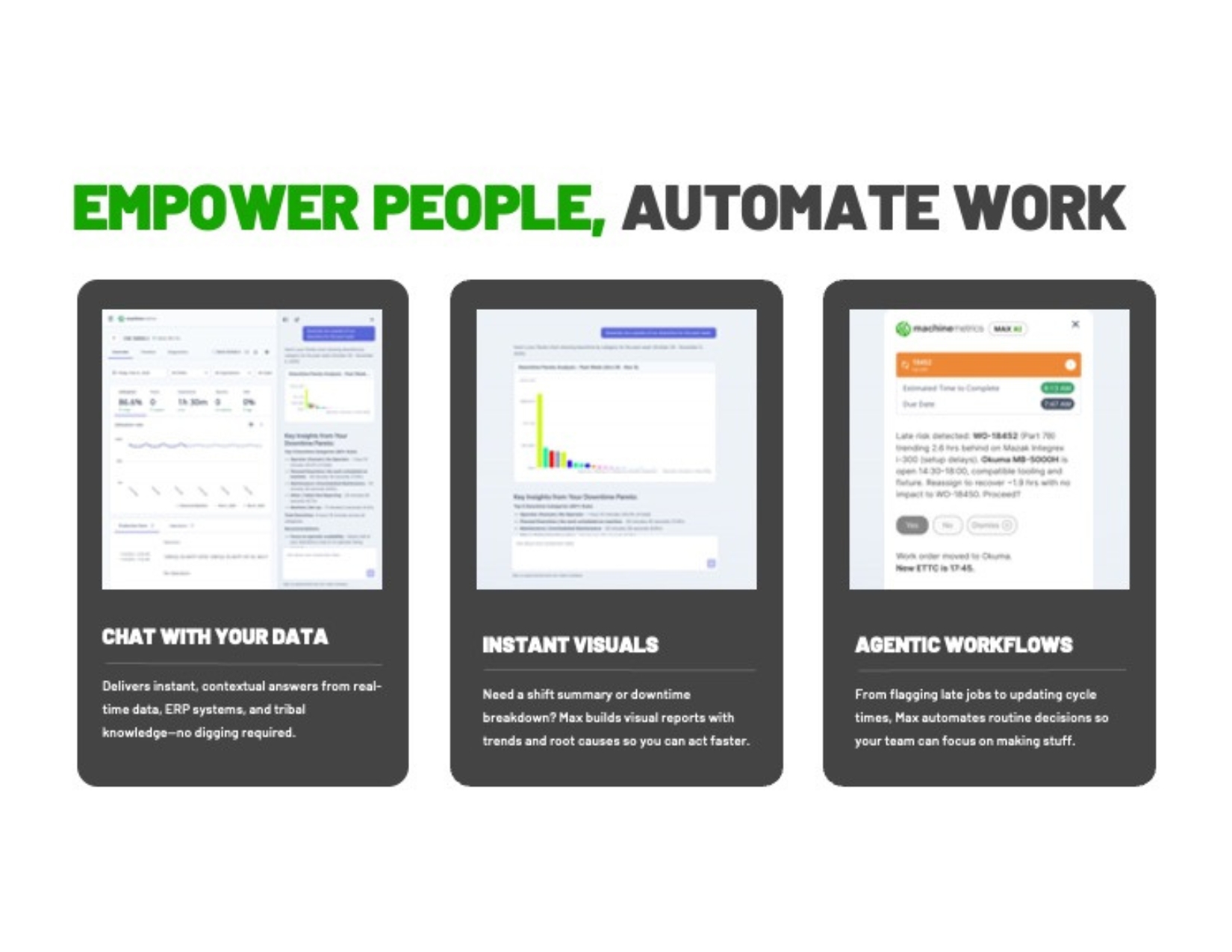

Can you un-tribalize knowledge? This is how MachineMetrics aims to tackle the frontline skills shortage challenge. They are creating a fleet of agentic digital coworkers as part of the Max AI addition. These agents have full access to the unified data model, so they know what’s happening and when, as well as who needs what data at any given moment.

Like a good expert coworker, the human workers can engage with these digital coworkers using natural language prompts. The system can find data, provide quick responses to questions, adjust and direct, or even automate core production tasks. It can also create a software widget for ongoing use for issues that arise on a regular basis.

One example of a specific agent is for shift note handoffs. The agent can automate the basics, since it has access to the full record for that shift, and operators can augment that with their own annotations. Another is for Continuous Improvement (CI), and the analysis capabilities of Max AI can help everyone be involved. The CI agent can greatly speed up data analysis and understanding, allowing people to focus their efforts where they will make the most impact on performance.

Configure the UX

Digital coworkers are great, and people also need all elements of their experience with MES to be intuitive and match their expectations and specific job needs. MachineMetrics claims all screens are now configurable. A widget framework for building the UI enables drag-and-drop and adjustable customization to tailor screens so they truly support users. With the LLM-based capabilities of Max AI, customers can add a summary to a dashboard.

They claim some of this can replace Power BI and other data analysis and visualization tools for customers. A significant upgrade in functional scope this year has enabled MachineMetrics to be a more comprehensive single platform for the frontline than it was before. MES, scheduling, analytics, and data from connected machines and other software feeds any needed data through this single interface.

Beyond the unified data model, the software now also features a Knowledge Hub, where manufacturers can upload and centralize any knowledge they need. MachineMetrics has already uploaded thousands of machine manuals. Customers can provide work instructions and SOPs, safety and hazardous materials information, and generate documents based on experienced and skilled workers’ knowledge on any topic.

Even snippets from these experts can contribute to success if they leave or retire. For example, each machine may have a different impact when it’s down. The experts know whether a 10-minute downtime is important to address or not; when a particular vibrational pattern is likely to lead to a downtime event, and more.

All of this expert knowledge in a central location can be beneficial, as anyone who searches for the data they need to act knows. The Knowledge Hub is also part of what agents use to make recommendations.

The Knowledge Hub augments the rich set of data models, time-series data stores, vector and graph databases, and APIs. All of this builds on the original connectivity through APIs that got MachineMetrics its start.

What’s Next

MachineMetrics plans to release new agents soon. The shift handoff agent is scheduled to launch in 2025. After that, in early 2026, an agent to automate scheduling is due. The goal is to change behavior for operators and other manufacturing and production support staff.

The team believes that frontline workers require an easy, intuitive user experience, with access to the real-time data they need. This encompasses not just the task at hand, but also improving it and solving problems.

An onboarding agent aims to improve the implementation and rollout of this young MES. The company has already structured itself for long-term customer relationships in a land-and-expand manner. They have three main teams: Commercial, Product, and Technical Solutions that provide implementation.

Our Take

MachineMetrics is rapidly making the transition from its machine monitoring roots to MES and an industrial data management system. While some of the core MES functionality is just coming online, the data structures and AI approach seem solid. These, along with the existing customer relationships, will form the foundation for continued growth and delivering value to customers.

Discrete manufacturers seeking a rapid approach to get up and running, both to keep equipment humming and empower operators, may find MachineMetrics worth exploring. Current customers are the focus, and they have reason to celebrate the rapid expansion of functionality and AI capabilities.

Thank you, Graham Immerman and Rutherford Wilson, for updating Rick Franzosa and Julie Fraser on Max AI and MachineMetrics’ progress in the market.