When is machine monitoring no longer enough for a discrete manufacturer? When machines are no longer the bottleneck in the production process.

Graham Immerman posted on LinkedIn, “Machine monitoring is dead.” This was a shock, as he has helped build SaaS and user-friendly machine monitoring pioneer MachineMetrics. It was his way of saying they now address this broader issue and have expanded into MES.

Full Production Process

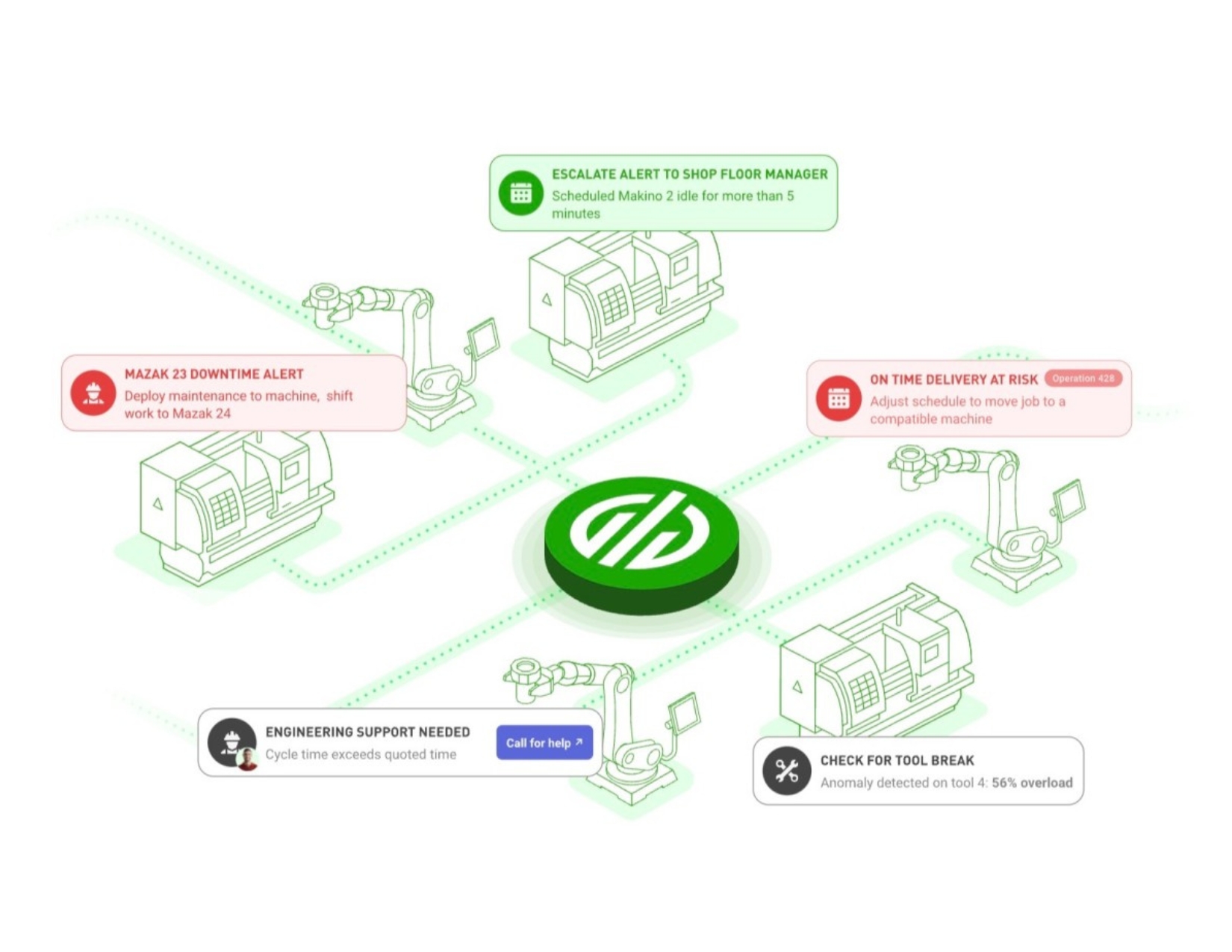

Machines are only one element of production. Nearly every manufacturing process also involves other resources, including tooling, materials, and people. Monitoring and improving production may include issues around quoting, scheduling materials, directing operators, and more. This is MES territory, and MachineMetrics’ real-time machine status can help inform the other processes.

The new MES pulls work orders from ERP with a single click and tracks them through the plant floor in real time. The cycle time analytics at the core of MachineMetrics can help understand where the operation is ahead or behind schedule. This, in turn, can help make dynamic changes to the production schedule on the fly.

What is Needed

Many customers believe they want machine monitoring and benefit from it. However, once they get it, they realize they are still missing delivery dates. MachineMetrics has seen this pattern and say they are dedicated to giving customers what they need, not just what they think they want.

They need full MES, including detailed scheduling that tracks not just orders but assets. For many of these mid-market discrete companies, this will replace white boards, Gantt charts, Kanban boards, and Excel. Now, the plans are in the digital system and can change based on actual activity. The system will show late orders.

MachineMetrics’ new MES has fully configurable dashboards, which are essential for making good decisions. It also includes a full BI tool for SQL queries and managing ERP data, enabling real-time MES data flows.

Machine Connectivity Boosts MES

MachineMetrics’ MES stands out because of its machine monitoring roots. Many mid-market ERP and assembly-oriented plant floor systems are not very good at connectivity to the wide variety of machines in discrete manufacturing environments. Since this was the company’s origins, that’s inherent in this new MES.

MachineMetrics has always believed that more and more automation will come into play. The machine-centric nature of their architecture has consistently shown that. Naturally, they designed this MES to accommodate shifts in what is manual vs. automated.

Empowering Operators

Despite the machine-centric roots, MachineMetrics aims to empower operators, not remove them. They understand that people must set up tools, do maintenance, conduct quality checks, code downtime reasons, and more.

A simpler labor screen enables operators to use the MachineMetrics interface for all of their work. This is crucial to both efficiency and supporting less experienced workers. The system focuses on discrete manufacturers and includes intermittent ticket submittals, labor reporting, and tabs to pull up visuals such as work instructions or manuals.

An early example of analytics for specific needs is roll monitoring. In industries where material comes in rolls, the system has a countdown clock to anticipate roll ends and the need for changeovers and tooling changes.

AI Models Included

This first release of the MachineMetrics MES has AI models for both tooling and scheduling.

- Tool anomaly detection AI is a model that can prevent tool breakage. It uses anomalies detected in the machine monitoring process (without adding new sensors for Fanuc machines) to identify microfractures or issues that could lead to bad cuts or broken tools. The MES can then place a hold on the machine to prevent problems.

- At this first stage, scheduling uses AI to slot work orders from ERP into workers. It gets real-time feedback as it’s running and can adjust the schedule based on the estimated time to completion. As with all good production scheduling, it understands the tradeoffs between minimizing changeovers and setups vs. running upstream processes for JIT delivery to later steps in the process.

Speeding Implementation

Another challenge MES has historically had in the mid-market is that it can take a long time to get fully connected and in production. While MachineMetrics has traditionally advocated for connecting machines first, it is now seeing that with the full MES solution, that may not be ideal. If companies start with connecting into ERP to get work orders, they can get tracking and scheduling right away.

This could improve time to value compared to running network cable and connecting all of the machines first. The company has been honing connections to some of the more prevalent mid-market ERP platforms and has an SQL-based connection strategy.

Staying Connected

We are delighted to have this significant update briefing from MachineMetrics. Thank you, Graham Immerman, for getting us up to date. We look forward to connecting with you when additional major news and progress emerges.