We recently had the opportunity to reconnect with aPriori Technologies, a company we’ve known for years. It has been exciting to watch their solution evolve from a product cost management tool into a comprehensive digital manufacturing intelligence platform. Today, their platform enables improved decision-making across sales, design engineering, sourcing, sustainability, and manufacturing.

Who They Are

aPriori’s cloud-based platform simulates manufacturing processes to deliver real-time feedback on cost estimates, manufacturability, cost drivers, and environmental impact. They say their solution, with its process-specific, regionalized manufacturing models and enterprise data integration, helps companies win new business, improve margins, and avoid manufacturability issues.

The system models the entire production lifecycle, taking into consideration part geometry, material, manufacturing process, and regional cost data. Leveraging hundreds of manufacturing processes and tens of thousands of materials, teams can run what-if scenarios, compare alternatives, and make early, data-driven tradeoffs when changes matter most.

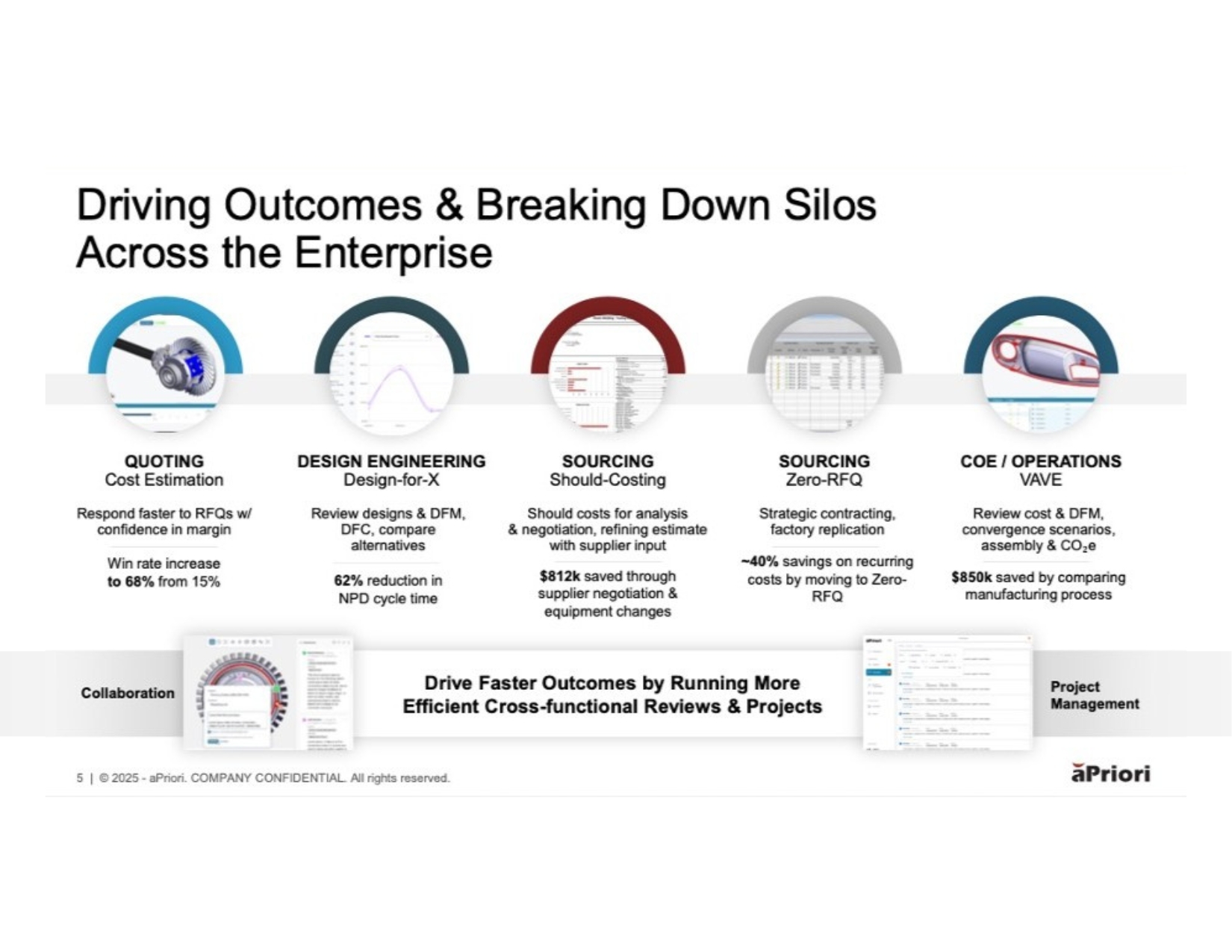

aPriori supports multiple product lifecycle stages, from quoting and cost engineering through design and sourcing. The platform provides:

- Manufacturing simulation: By modeling real-world processes (machining, molding, casting, additive manufacturing, assembly, etc.), it provides design for manufacturability (DFM) feedback, cycle time estimates, and associated costs and carbon footprint. Detailed cost breakdowns include labor, machine, tooling, and material.

- Integration and enterprise support: It connects with PLM, CAD, and sourcing systems to leverage existing data and automate analysis across parts, assemblies, and entire BOMs.

- Sustainability alongside cost optimization: Users can evaluate carbon footprint and energy consumption in parallel with cost.

- Usability: The platform features a drag-and-drop model import tool, guided process selection, and scenario comparisons, making it convenient for design engineers, cost analysts, and sourcing teams.

What Makes Them Different

According to aPriori, several factors differentiate their solution:

- Automated insights: Continuous cost, carbon, and DFM governance is available through PLM-triggered analyses and automated alerts for cost or manufacturability exceptions.

- 3D CAD intelligence interprets geometry to assess manufacturability, cost, and sustainability implications. Design engineers can leverage this intelligence inside CAD.

- Extensive digital factory models offer more than 400 manufacturing simulations, providing insights into potential production approaches.

- Comprehensive feedback encompasses cost, manufacturability, and sustainability, delivering actionable insights, which they say takes only seconds.

How They Help

aPriori says its customers use the platform to solve three primary challenges:

- Improve product margins: Many companies lack the time or resources to analyze cost. With aPriori, they can quickly identify cost drivers. For example, Rivian reduced its BOM cost for the R1 model by 20–25% using aPriori.

- Reduce NPI delays: The late discovery of DFM issues often results in engineering change orders (ECOs), delays, and increased costs. aPriori flags issues like thin walls or improper tolerances early, before tooling or sourcing decisions are made. Dana, a large automotive supplier, achieved 8% cost savings, half of that in the first year, largely through fewer late-stage ECOs.

- Win new business: Accurate cost estimates take time, especially if there isn’t past work to reference; however, the competitive advantage often goes to the supplier who responds first. aPriori can quickly produce accurate quote estimates, accelerating the time to produce a bid. Flex improved its win rate from 15% to 68% by using aPriori to accelerate quoting while protecting margins.

Our Take

Tech-Clarity’s State of Product Development: 7 Trends Shaping Product Innovation research highlights top challenges facing product development:

- Supply chain disruptions / market volatility

- Design-to-manufacturing handoff bottlenecks

- Growing product complexity

- Time wasted on manual or repetitive tasks

- Difficulty hiring and retaining skilled technical talent

aPriori seems well-positioned to help manufacturers address all of these challenges.

In an era of volatile supply chains and unpredictable costs, predictability in cost and sourcing can be a competitive advantage. aPriori’s ability to model what-if manufacturing scenarios across regions could help. For example, comparing production in China, Vietnam, Germany, Brazil, Mexico, or the US extends its value beyond cost optimization to supply chain resilience and agility. The solution could help hedge against volatility and enable companies to plan and pivot with greater confidence.

aPriori describes their solution as having a “manufacturing engineer in your pocket,” with its ability to embed process expertise into the product development lifecycle. Not only can this help address bottlenecks in handoffs to manufacturing, but it can also help overcome knowledge loss due to the retirement of experienced engineers. Retirements are eroding decades of tacit knowledge, while many younger engineers have limited shop-floor experience. It can help identify manufacturability issues earlier, despite growing complexity, and automate many manual tasks required to support decision-making on cost, manufacturability, and sustainability.

As younger employees join the workforce, a cultural shift is taking shape. As digital natives, they are adept at using technology for decision-making, rather than relying on years of accumulated experience and rules of thumb. As product complexity increases, decisions will become increasingly difficult, so this new generation will likely accelerate the adoption of intelligent solutions like aPriori to support better-informed decisions.

Given current market trends, aPriori appears well-placed to support manufacturers amid economic change and workforce evolution. The company’s next wave of innovation will center on AI-driven guidance, from sourcing coaches to intelligent DFM assistants, which should build upon their existing capabilities. The appointment of a new CTO with deep AI expertise demonstrates a commitment to this strategy.

We look forward to seeing how these developments further expand aPriori’s role in shaping the future of embedding manufacturing intelligence into the product lifecycle.

Thank You

Thanks to Rick Burke, Chris Jeznach, and Mark Rushton for briefing us.