At the heart of any manufacturing operation are the assets it uses, and MaintainX has been growing rapidly by helping companies’ maintenance technicians manage and maintain their equipment. Recently, the company received an additional round of funding, boosting its valuation from $1 billion to $ 2.5 billion. Fast growth earned it a #48 spot on the 2024 Deloitte Fast 500 US list and on the 2025 Forbes Cloud 100 list. In its seventh year of business, MaintainX is adding an array of new and upgraded features to their mobile-first, AI-powered asset management system.

The MaintainX platform includes Modern Asset Management, Machine Health Monitoring, and Intelligent Maintenance. Companies use these increasingly widely. Each area has some new or updated features.

Updates to Modern Asset Management

The core capabilities in the asset management part of the suite include surface-level asset insights, such as usage and performance, streamlining maintenance, maintaining a unified parts inventory, and real-time reporting. Upgrades include:

- Root Cause Analysis (RCA) now has additional functionality for dictated inputs, as well as enhanced reporting and export capabilities through the API.

- GPS-based work order check-in ensures the right work is done in the right place. For field or yard-based operations, this location validation is beneficial.

- Permit to Work (PtW) has better configurability to dictate how procedures, checklists, and steps are assigned out, so safety and operations folks can specify when work has to be done. Permits can ingest, restrict, and dictate SOPs.

- Purchase Orders can now be created, edited, and managed on mobile.

- Floor plans now feature a visual map, and companies can add asset status to those views from OT or SCADA systems, displaying asset status in color-coded labels. We view this as a form of plant digital twin, featuring live data on a visual display that matches reality.

Updates to Machine Health Monitoring

Using real-time machine data to detect issues and act quickly to prevent downtime is crucial. This part of the suite includes connecting to SCADA and IoT, real-time condition monitoring, anomaly detection, and automating actions using If/Then logic. New capabilities include:

- Asset monitoring view to see real-time data for all sensors on each asset in the hierarchy. They can all map into a single graph for analysis or compare and contrast. From here, anomaly detection can automatically trigger workflows.

- Vibration monitoring sensors are now directly available from MaintainX for customers seeking a one-stop solution. This can be used self-service or full-service, where MaintainX’s vibration experts help identify and resolve issues based on the data.

- OT integrations have expanded beyond Ignition to Kepware and MQTT. The benefits of MQTT include structuring context through metadata and multiple partners to ensure robust machine-to-machine data flows.

New in Intelligent Maintenance

The Intelligent Maintenance part of the software suite delivers AI-driven workflows and smart automations. The goal with MaintainX CoPilot is to maximize technician wrench time by providing support through natural language inquiries and more.

- CoPilot for Reporting: Earlier this year, MaintainX introduced its AI-based CoPilot for point-of-use guidance and support, and the new feature adds visualization of the results of an inquiry. These graphs can be added into dashboards without the customer having a team to structure them.

- Work order suggestions support less experienced technicians by popping up procedure steps, answers to common questions, and directions for how to execute the work order, all based on the AI’s history of past work and SOPs.

- Streamline troubleshooting and research to deliver expert guidance in the field. The AI is trained on images, manuals, and work instructions. The technician can snap a photo, and the system will display the corresponding actions and work orders. These can be saved as templates.

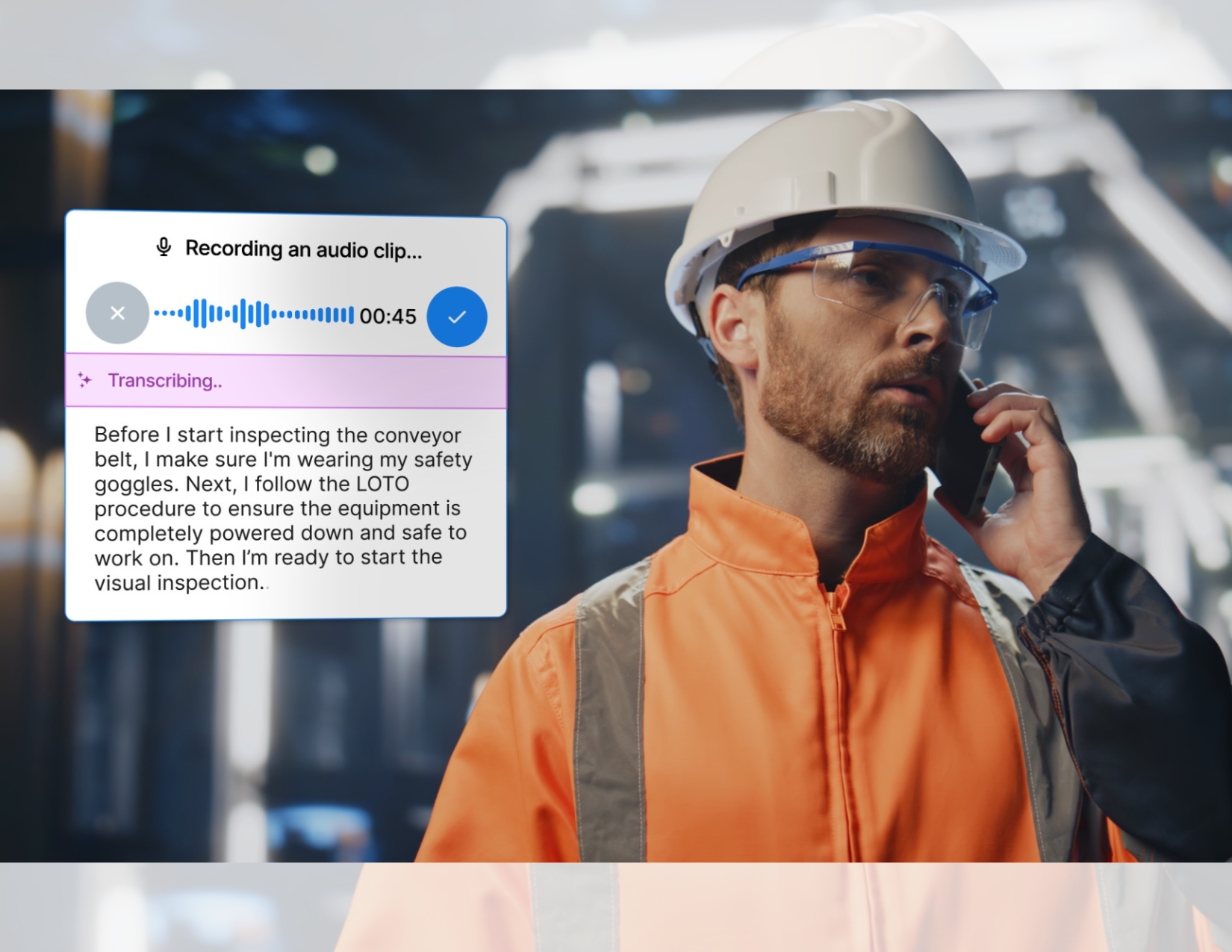

- Generating accurate work summaries enables technicians to record a voice note in their native language explaining what they did, and AI converts it to a structured summary for review and approval. This helps to build out the AI knowledge base.

- Forecast parts requirements based on leadtime information combined with MaintainX data on upcoming work to create a recommended reorder point and quantity. This optimizes spare parts and minimizes downtime and rush-order costs.

Repeat Funding, Recognition

MaintainX’s Series D funding is from their existing investors, Amity Ventures, BCV, Bessemer Ventures, and DE Shaw. We see this as a vote of ongoing confidence. And small wonder, the company is growing fast.

The company also made the Forbes Cloud 100 and SiliconANGLE TechForward awards this year. Beyond that, MaintainX got a ‘best’ in the G2 customer ratings on six different areas, including support, usability, and results, plus overall best for the category.

The customer base includes mid-size companies as well as large ones. They shared information about two of the larger ones. UPF Industries, in building materials, uses MaintainX’s new MQTT capabilities to connect sensors and PLCs for reliable real-time data. Oshkosh’s defense business uses the MaintainX CoPilot AI to unlock data from OEM manuals and legacy systems. They also leverage voice-to-text for accurate data logging.

Great Progress

In just seven years since their founding, MaintainX has made an impact on the market. The continued growth in revenues and functionality shows good momentum. Thank you, Sven Litke and Tessa Van Straalen from Kea Company, for setting up the briefing with Justine Crosby and Colin Morris for our Jim Brown and Julie Fraser.