Can manufacturers gain an effective digital twin capability spanning from product concept to supply chain, production process, production execution, factory automation, and controls? Dassault Systèmes believes it can deliver that today. Their UNIV+RSES vision expanded deep into the plant floor with their July acquisition of Ascon’s Qube technology and team. This new edge-to-cloud platform complements the other rich elements of DELMIA’s digital manufacturing and manufacturing operations management software offering.

Dipping into Virtual Automation

This recent technology acquisition extends Dassault Systèmes’ capabilities to replicate the real world in virtual form, all the way into equipment controls and automation. Dassault Systèmes has an extensive software portfolio to create digital twins of reality. The company grew initially as a product design and development leader, and the DELMIA brand has long focused on production and supply chain operations connecting the virtual and real worlds.

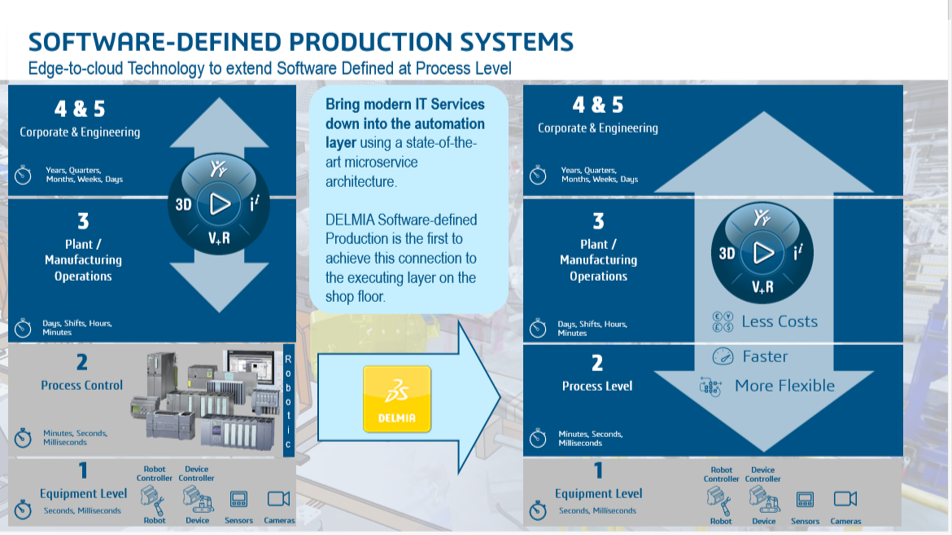

With the addition of Ascon technology, DELMIA aims to deliver software-defined production systems to improve highly automated manufacturing environments. Not just modeling, but replacing, vendor-specific programming of programmable logic controllers (PLCs) at level 2 of the Purdue model, would be a breakthrough. Challenges at the automation layer are many and cause huge costs and inefficiencies for large, highly automated manufacturers.

Vendor lock-in at the automation layer with proprietary hardware, software, and data formats is nearly universal. Initiatives like the Open Process Automation Forum (OPAF) are striving to break the lock; adding this virtual approach could accelerate the progress. Due to the low level of interoperability, the real-time data from these OT systems often cannot be easily accessed by the plant IT systems, such as MES. This harms decision-making speed and effectiveness. The DELMIA team rightly points out that automation setup is labor-intensive and often lacks efficiency and insights. This new technology will help alleviate these issues.

Based on early experience in automotive, DELMIA expects significant benefits for customers. Major areas include expanding transparency, improving agility to respond to changes on the shop floor, reducing line changeover and new product introduction time. They cite 30-50% reductions in line-level operating cost, changeover and downtime, to name a few.

Recipe Management and Tech Transfer

Batch process industries may be interested in the Virtual Twin of the Plant as a Service offering. In process industries, the production process determines the product, so this process twin is a foundation for quality, yield, costs and sustainability. Without the manufacturer needing to buy software, train people and create a digital twin of a plant, DELMIA will do it for them.

This process digital twin supports tech transfer in batch process industries as well. Moving from the R&D lab (where Dassault Systèmes’ BIOVIA brand is strong) to production typically presents significant challenges to optimize equipment, processes and people. As life sciences companies also create combination devices, R&D may encompass active ingredients, process development, hardware and software. All these ideally feed into a coherent package for tech transfer into scaled-up production.

And then there’s recipe management – not just developing, but managing recipes on an enterprise basis is an enormous challenge. Following the ISA88 transformation models is a start, but few have the software to enable those transformations from R&D formula to general recipe to site recipe to master recipe to control recipe. Using the 3DEXPERIENCE® platform on the cloud with an array of applications, DELMIA hopes to deliver improved efficiency and consistency to biopharma, pharmaceutical, and CPG customers.

Growth Across Industries

While the Ascon technology acquisition focuses on core complex discrete industries and the tech transfer and recipe management on batch industries, these are not DELMIA’s full spectrum of customers. The DELMIA Apriso MES/MOM continues to win large multi-site deals across a wide array of industries.

They mentioned wins as a battery manufacturer, life sciences, metals and A&D companies. One was a win-back from another MES provider who got the first plant up but could not scale cost-effectively to other sites. The DELMIA Apriso multi-site advantage comes from a longstanding (at least 20 years) focus on enterprise deals and fine-tuning their rollout capabilities.

Looking Forward

Dassault Systèmes’ 3D UNIV+RSES vision focuses not only on modeling or simulating the real world but also on generating it. (See Jim Brown’s insight from the Dassault Systèmes analyst event for more on this concept.) Now, the ability to mirror and generate new products stretches from R&D through supply chain, manufacturing and digital automated controls.

Thank you, Eric Green, Michael Bradford, and Tom Muth, for the update briefing. We have watched the DELMIA portfolio grow, improve and be merged into the greater Dassault Systèmes solution set and we look forward to watching as more of the vision comes into reality.