Might international standards for data exchange and interoperability between trading partners worldwide finally take hold? Could multi-enterprise manufacturing networks get cost-effective data flows in an open, vendor-agnostic network? That’s the intention of International Manufacturing-X Council (IM-X). Michelle Boucher and I had an opportunity to learn about this new consortium of 10 nations from CESMII (The US’ Smart Manufacturing Institute) CEO John Dyck.

This is an urgent need. Our research shows that over two-thirds of manufacturers spend a lot of time, effort, and expertise to integrate and maintain integration between MES, quality, maintenance, scheduling, IoT, and machine or equipment data. From 2020 to 2023, this did not improve. And that’s just in the operations. Extending integration so data flows across the enterprise and supply chain compounds that challenge.

CESMII has been advocating for the best interoperability standards in manufacturing enterprises and plants. The goal is to democratize digitalization by commoditizing (or turning open-source) aspects that are not proprietary. This new consortium takes work CESMII has been doing – and some it has done jointly with Germany’s Platform Industrie 4.0 – more global and into the supply chain.

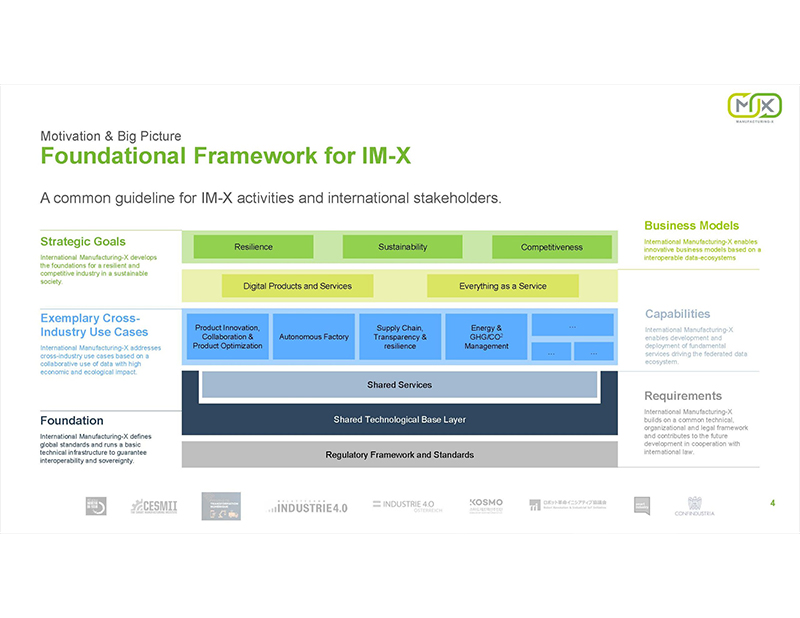

IM-X’s vision “is to enable open, global and cross-industry operation of cost-effective data networks. This will be realized through three sets of strategic initiatives:

- Connect value chains and manufacturing data networks across supply chains, industries, and countries

- Implement global foundations for data-driven resilient, sovereign and climate-neutral production covering the full life cycle of production and products

- Enable innovative value creation in an interoperable and sovereign data ecosystem.”

They plan to implement a global, cross-industry data ecosystem for smart manufacturing. If they succeed, IM-X’s work could transform global trading capabilities for manufacturing industries. Dyck compared it to the US’s Interstate Highways program started by Eisenhower in the 1950s. Easy information access through the best available technology could enable more companies of all sizes to succeed.

IM-X is focusing on creating a federated, decentralized, collaborative environment. This pre-competitive work enables countries to contribute to an open-source or crowdsourced network. Data continuity (internally and externally) is the foundation for visibility and collaboration, which our research shows are crucial to success.

Each country has one vote in this council. The ten nations and organizations involved are

- the USA (CESMII)

- Germany (Plattform Industrie 4.0)

- Austria (Plattform Industrie 4.0 Österreich)

- France (Alliance Industrie du Futur)

- Australia

- Canada (Offensive de Transformation Numérique)

- South Korea (KOSMO)

- Japan (RRI)

- Italy (Confindustria)

- the Netherlands (Smart Industry)

IM-X plans to use existing work from these nations and organizations. The council first convened this summer. They are already thinking about policies, trust frameworks, and legal frameworks. Other countries may also join in the future.

The well-rounded makeup of CESMII and many of these organizations bodes well. A mix of industry, government, academia, software vendors, and machine builders using carefully vetted and impartial funding helps to capture and consider all perspectives. This “institute” format has been a proven approach for advancing manufacturing in Germany.

Reconnecting with my long-time friend and colleague John Dyck was a delight. We are excited to learn about CESMII’s US representation in this new consortium. We will stay tuned for news from CESMII and IM-X.