Modern Operations Software

The founder, Eric Klement, is ex-Infor and saw a need for simple MES solutions for smaller or less complex manufacturers. The goal is to implement the JobControl and StockControl apps in three days, which is possible because the apps are intuitive and user-friendly. This combination of speed and ease enables quick time to value.

The software is based on REST APIs and the Infor OS gateway. These make it flexible, modular, lightweight, easy to connect, and modern. Traditional software providers may struggle to match the performance of REST APIs with older technology.

Implementation Speed

Preconfigured apps are a crucial foundation for the three-to-five-day implementation time. Yet that’s only one component. A joint workshop between the customer and software provider’s team sets out needs, processes, and priorities. Pre-built connectors to Infor LN ERP for data the app needs and for ERP updates of actual shop activity accelerate implementation, too.

Smart Production Solutions and Infor train the manufacturer’s trainers to sustain the system. The system is configurable to support non-IT professionals in configuring and maintaining the software. All customers are always on the same instance and version, with no possibility of software that gets outdated.

Intuitive

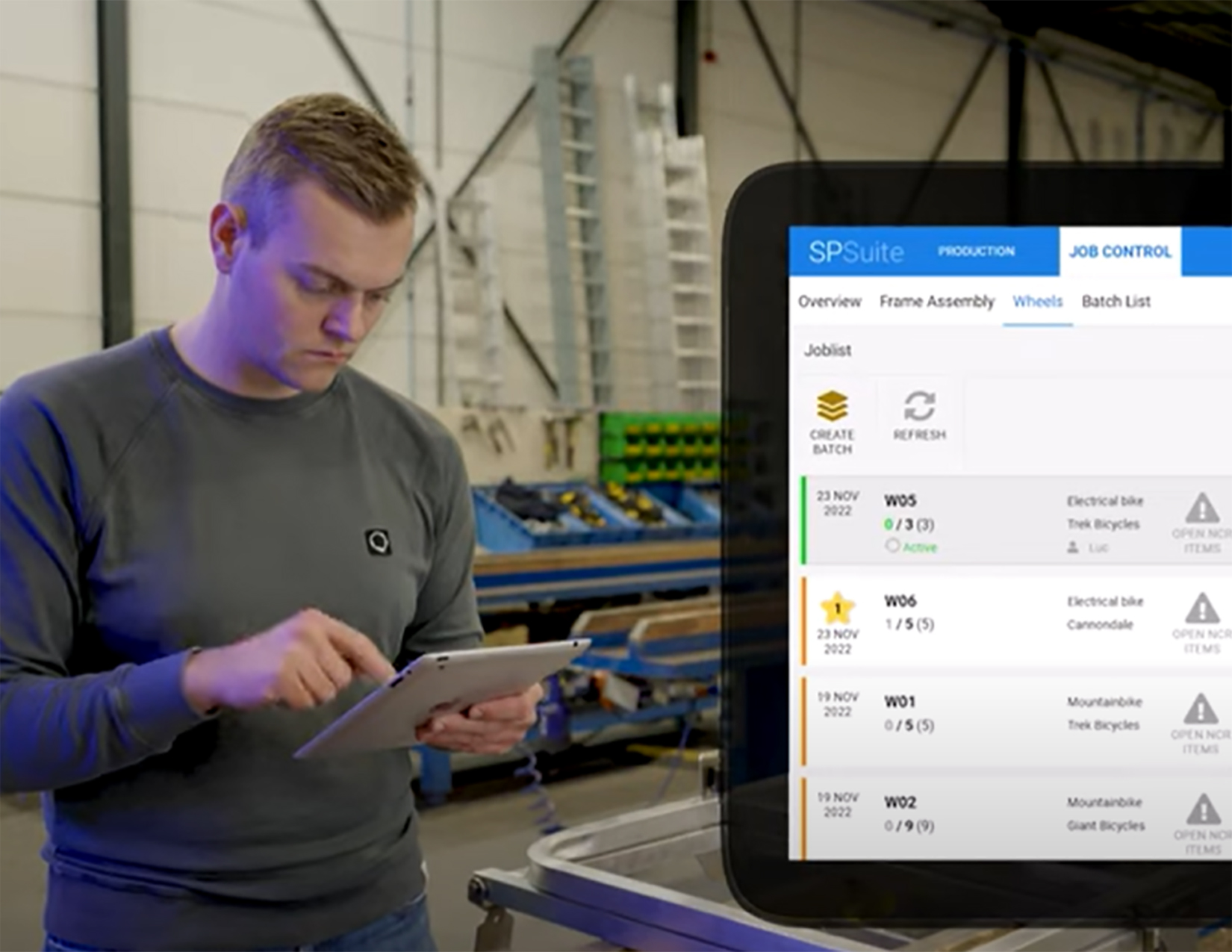

The software shows frontline workers precisely what they need for their next task on a touch screen. Each person sees the screen in their native language. Companies can decide whether every workstation will have a screen or whether workers will share the screens. Licensing is by device, but at $65/device/month, most companies will opt to have several screens to prevent work slow-down when workers queue up to await their turn at the software.

Production work orders are the basis of the JobControl section. The status of the work order is always available. Color coding can show what material is available and what is not. In addition to setup, start, machine, and label printing, the operator can see reports such as OEE with a button click. Deviations can alert a supervisor via email.

StockControl focuses on warehouse activities such as goods receiving, picking, and kitting for orders. Matching quantities to purchase order quantities enables ERP updates. If there is damage, the worker can take a picture and send the exception back to ERP. The goal is to keep frontline employees in the factory and have procurement teams talk to suppliers if needed.

Smart Production Solutions aims to complement ERP, not overlap with it. The work orders and, if applicable, serial numbers for parts, subassemblies, and the final product, come from ERP into the apps. This enables full MES track and trace, yet a light footprint and applicability to smaller ERP customers. The approach has paid off, as JobControl and StockControl are available on the Infor price list and in their MarketPlace.

Lower-Risk with Parent

Smart Production Solutions is part of the Otherside Software group. Otherside Software is a Dutch software development company. With over 150 employees and a yearly growth of >20% since 2015, the group bootstrapped the company into a mature software company with a proven track record. The group has its own SaaS platform.

This SaaS platform delivers security, testing, and an environment that enables subsidiary companies to offer credible SaaS apps. With the infrastructure shared, companies such as Smart Production Solutions can focus on their areas of domain expertise.

Moving Ahead

The company has primarily focused on selling in Europe, where its headquarters are. However, with Infor’s worldwide presence, they are also expanding into Asia and the Americas. Infor provides first—and second-level support for customers. Infor partners are starting to be trained on the JobControl and StockControl apps. The company hopes to forge relationships to extend other ERP platforms over time.

Thank you, Eric Klement, CEO, for taking the time to get us up to speed on your lightweight approach to extending ERP for production and shop floor inventory operations. We look forward to following your progress in the market.