Can ISA95 rescue large manufacturers’ digital transformation efforts? Early evidence suggests that it can, when deployed as a knowledge graph, exposed as the schema of a standard data model. The ISA95 standard is the basis for the ontological structure of Rhize Manufacturing Data Hub. This headless, event-driven, real-time system provides a clean, single source of truth for manufacturing data. Companies across discrete, batch, and process industries are using it already to address problems they had previously tried and failed to solve.

Can ISA95 rescue large manufacturers’ digital transformation efforts? Early evidence suggests that it can, when deployed as a knowledge graph, exposed as the schema of a standard data model. The ISA95 standard is the basis for the ontological structure of Rhize Manufacturing Data Hub. This headless, event-driven, real-time system provides a clean, single source of truth for manufacturing data. Companies across discrete, batch, and process industries are using it already to address problems they had previously tried and failed to solve.

Manufacturing Data Hub

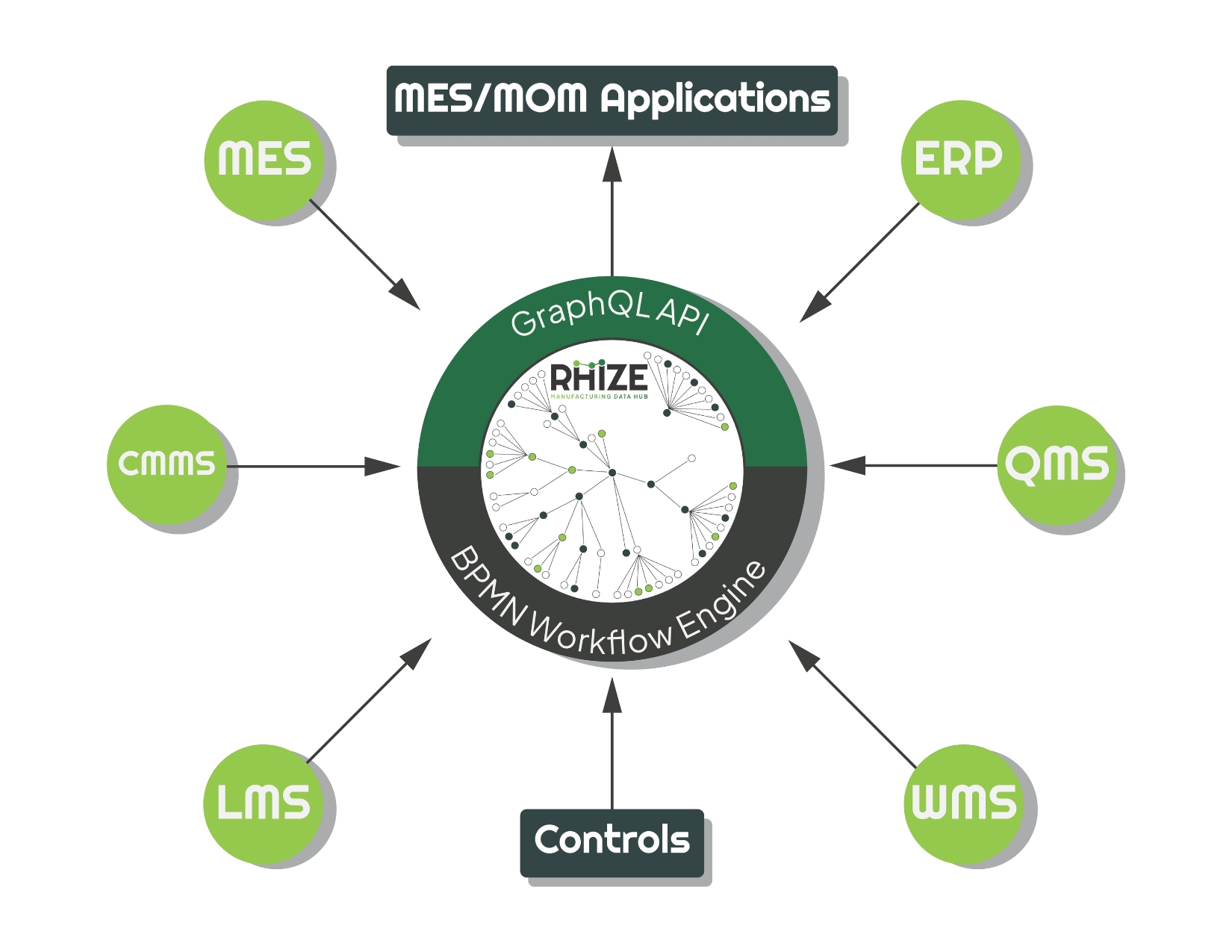

So, what is this Rhize Manufacturing Data Hub (MDH)? The MDH includes the ISA-95-based ontology, model and transactional storage (graph) and time-series storage, complex rules processing, a workflow engine for modeling, and a single access point GraphQL API.

It is a headless manufacturing system, meaning that applications are built via access to the GraphQL API and Workflow Engine. By converting all incoming operational data to comply with the ISA-95 schema, the platform acts as a Rosetta Stone for the existing disparate data models. ISA95 defines how to model and structure entities and the relationships between them for optimal interoperability.

Every system (MES, ERP, CMMS, DCS, Historian, etc.) can connect to this hub. The hub will convert that data into the MDH standard and insert it into the knowledge graph with its properties and myriad relationships.

The goal is to avoid the common problem of managing manufacturing data and processes across disparate systems with their own databases and structures. An ontology is a complete description of a domain that shows the properties and relationships between every piece of data. With the diversity and interconnectedness of equipment, personnel, and material data, this is no mean feat in manufacturing.

These are often not just parent-child or simple relationships, and the MDH ontology can represent them accurately using the ISA95 elements. Each entity exists only once in the MDH, making it truly a “single source of truth.”

The Foundational Digital Transformation Challenge

Our research shows that Rhize’s declaration that “data modeling and governance are the root of every problem for digital transformation” is correct for the technology. (We feel it ignores some crucial people and process issues.) To overcome this, Rhize has created a standard data model with an API to ingest and convert data from any source into a comprehensive ontology. With this structured approach stored and exposed as a knowledge graph, Rhize aims to make data mismatches, IT/OT disconnects, and dirty data issues problems of the past for its customers.

This also addresses a challenge companies face with AI: getting high-quality in-context data for data scientists. The number one challenge companies face is their data for AI and analytics projects, so this is excellent news for continuing rapid adoption and benefits from AI for large manufacturers.

Addressing Other Challenges

In addition to that foundational issue, the MDH can do more.

- Replace MES/MOM when it becomes outdated or unsupported. Rhize MDH enables companies to replace MES and MOM applications incrementally using an approach called the Strangler-Fig method. No rip and replace of systems is required.

- Overcome data and discipline siloes for better and easier data context. With this Rosetta Stone, each discipline can keep its systems and still agree on a single source of truth.

- Solve specific intractable problems. Rhize customers have tackled initial use cases that have been nagging issues that previous approaches could not solve.

- Expanding use cases rapidly across a large enterprise with multiple sites. MDH customers are deploying multiple functional capabilities simultaneously across one site and multiple sites, using an iterative process call “use case stacking.”

- Leveraging existing data relationships for new applications. The central ontology means that each new application can build on the previously defined data and relationships.

Leveraging Standards

Rhize has developed its MDH with standards at the core, including not only ISA95 but also BPMN for business process model notation, GraphQL API for exposing the knowledge graph in a natively introspective way, and MQTT and OPC UA for OT input.

At the heart of the Rhize manufacturing data hub is the ISA95 model. The dozens of manufacturing experts who created the ISA95 standard crafted a model that recognizes and enables a plant or company to model the environment precisely. People are arguing that it’s obsolete, but that may be because it is often shown layered on the Purdue 5-layer model, which is not an inherent part of the standard. Rhize has not yet encountered a use case that the ISA95 ontology could not accurately model.

Technology Basis

Other industries, like banking, have used headless data backends to drive digital transformation, separating applications and interfaces from data structures. MDH does that. Uniquely crucial for manufacturing, it handles both event-driven and time-series data.

All of this is stored in a knowledge graph. This ensures semantics, context, and data integration with many bi-directional relationships (known as edges in a knowledge graph). Whether IT or OT data, MDH is intended to be the translator or Rosetta Stone.

A drag-and-drop workflow engine sits on top of the graph but inside the MDH. Composable process modeling using the BPMN standard is crucial to the capabilities. MDH also uses a low-code approach to workflow and business process modeling.

Target Market

Rhize MDH will be most useful in the hands of large, enterprise-scale manufacturers. The criteria for their target customers include having:

- Multi-site (10+ is ideal)

- Multiple failed MES/MOM implementations

- Highly technically skilled and curious personnel

- Executive backing for a long-term program (often 3-5 years)

- An understanding and commitment to an ontological approach

Watching for Breakthroughs

Rhize says, “To be successful in an enterprise digital transformation and to enable innovation at scale, you must be able to iterate.” We agree. The MDH combination of graph backend, enforced ISA95 schema, ability to develop apps accessing the data via APIs, and composable workflow could do just that. We believe it could facilitate new levels of digitalization and MES longevity in many manufacturing environments.

Thank you, Kirt Anderson, for explaining the Rhize Manufacturing Data Hub offering. We look forward to following your progress in the market.