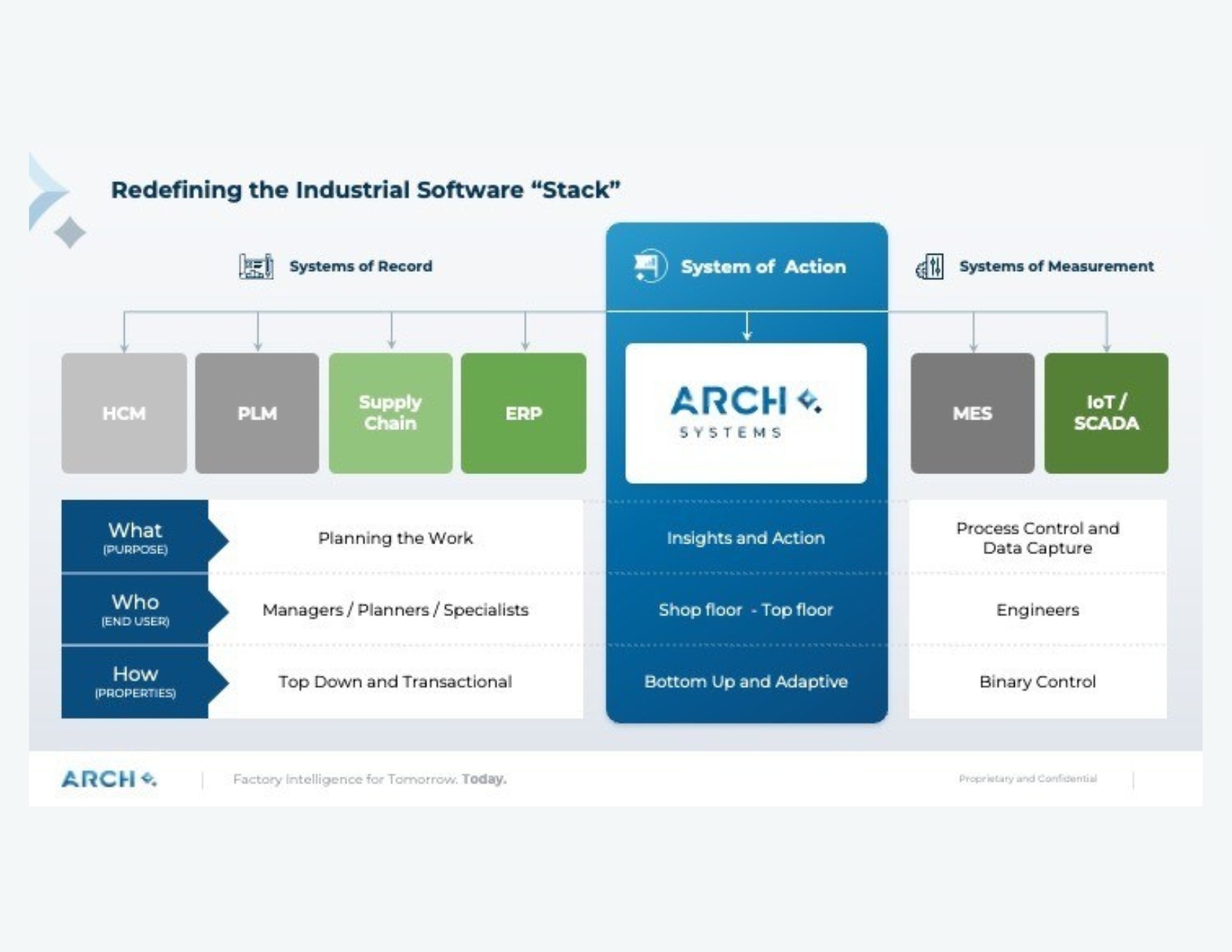

How can manufacturers gain the data connectivity, analytics, and AI capabilities necessary to make informed decisions with confidence? Arch Systems was founded to provide that, and it continues to accelerate customer success via, in their words, “Intelligent Actions for Manufacturing”. Arch customers are finding that building their own AI infrastructure does not make sense when they can purchase this pre-built architecture, which includes connectors, dashboarding, a knowledge graph for context, analytics, and AI capabilities. We are excited about the progress they have made since our first briefing in the summer of 2024.

Envision Unlimited 30-Year Experts

For many plants, the limiting factor in achieving excellent results is not a lack of data – in fact, most are overwhelmed with data – but a lack of experienced personnel. The Arch Systems vision goes beyond decision-making support into ensuring intelligent action in production. As you might expect, this takes the form of agentic AI-based factory experts.

As both manufacturing and AI experts, the Arch Systems core team recognized early on that they needed to provide not just alerts, but also concrete details, including recommended actions. Specific agents know various processes extremely well and will identify the root cause of a problem and identify a particular sequence of steps to perform to correct or preveniot problems. Traceable steps lead to measurable improvements in each agent’s focus area.

Arch Systems agents work with nearly any form of plant IT or OT data through API. Even for data without an API, Arch can interpret information on dashboards using a capability called Dashboard Vision. Remember that Arch Systems offers the entire stack, from data ingestion to a common knowledge graph, for any data the factory may need to take action.

Common Use Case Benefits

Arch claims some compelling customer value examples across a wide range of KPIs.

Downtime – One plant with an Arch site license focused on downtime and reported gaining $2.8M in a single year, an enormous ROI. Another reports $3.7M in hard savings over two years with no disruption to operations during deployment.

Machine Utilization – One CM was performing a full line freeze for every changeover, as requested by a customer. Conducting quality checks with AI in real-time resulted in a 97% increase in OEE.

CapEx Avoidance – With less downtime, higher quality, and improved yield, companies can defer or avoid adding equipment for increased throughput demands. One company reported $7M CapEx avoidance and ROI in less than three months as a result of visibility from Arch.

Quality – Like downtime, Arch focuses on tackling the investigation process. One customer reduced SMT line attrition by 12% in the first week of use, resulting in over $5,000 in monthly savings per line. Getting to root causes is valuable. For yield, Arch offers a “machine of blame” agent that can identify which machine is likely causing anomalies, automate root cause analysis, and provide recommendations on corrective action.

Powerful Partnering

Arch Systems not only partners with customers, but with a wide array of other software providers. Their technology integrates seamlessly with major cloud platforms and leading manufacturing systems, delivering unified insights and AI-driven intelligence. Strategic collaborations include Fuji, Aegis, NMTronics, and Dassault Systèmes, which extend capabilities and help customers accelerate digital transformation and operational excellence.

With MES partners, Arch’s intelligence can come through the MES UI or their own. Some MES providers offer robust dashboards, analytics, and data structures that are analytics-friendly, while others do not. So, the approach varies. What is essential in a tight integration is the Arch IIoT Event data layer and ontological model to link all aspects of the factory. Note that several of Arch Systems’ largest customers have a homegrown MES where Arch integrates and provides a superior user experience.

Customer Expansion

Arch Systems has achieved significant success in discrete manufacturing, including electronics, automotive, aerospace, defense, and medical technology. Because the expert data model or knowledge graph at the core of the software is based on modeling steps or batches, the company does not plan to serve continuous process industries.

In May, Flex issued a joint press release with Arch regarding their global expansion of an already strong relationship. In June, at the Manufacturing Leadership Council Rethink conference, Arch Systems’ joint customer announcement was with another enormous contract manufacturer, Jabil. Both companies’ COOs sit on the Arch Systems board of directors.

Contract manufacturers (CMs) are among the most accomplished manufacturers, not only in electronics but also in other types of manufacturing. As the manufacturing arm for other companies, they are expected to perform well across all production KPIs. Cost, quality, and speed are not tradeoffs, but all are expected to be excellent. Six of the 10 largest CMs are currently Arch Systems customers.

Bridges of Trust

Its research shows that the Arch AI Dashboard vision, paired with expert-guided reasoning models, can match or surpass human expert performance in root cause analysis and corrective action recommendations. It can do so much faster and less expensively.

Arch Systems appears to be living up to its name – the powerful and trustworthy bridge to support data in the factory crossing into the realm of intelligent action. Thank you, Andrew Scheuermann and Laura Horvath, for keeping us updated. We intend to continue following your progress in the market.