Value from Data

Value from Data

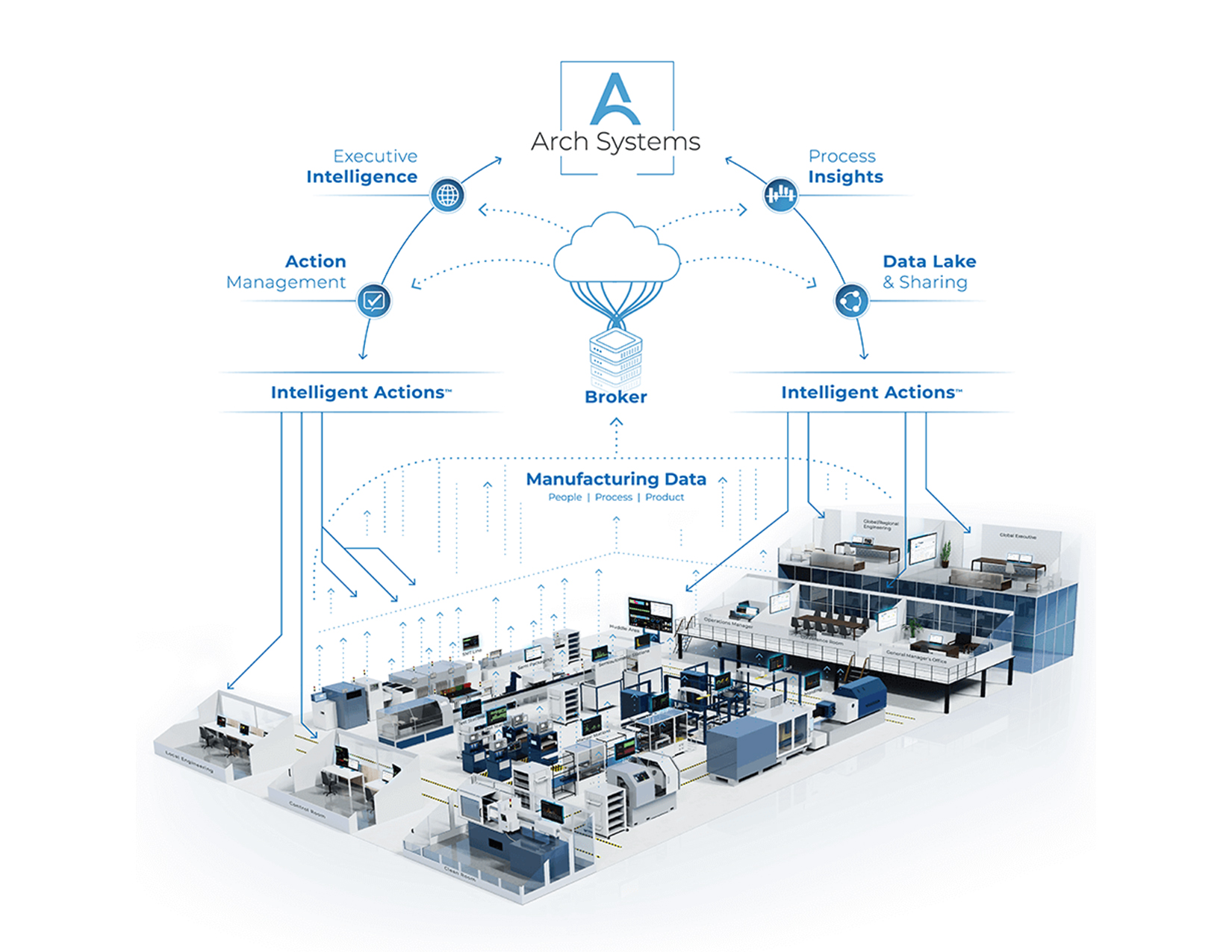

Creating value from the varied data in manufacturing facilities can be an elusive goal. In our recent briefing with Arch Systems, we got an idea of how they convert massive quantities of data into intelligent actions for manufacturers. They do this for frontline workers, top-floor executives, and many in between.

The premise is that quite a bit of data is available in a manufacturing organization that is drastically underutilized or unused today. Examples are machine data that exists but is not fully utilized, disconnected or less-automated machines and lines, and even companies that have invested in BI but not for all their data. As manufacturing demand for scarce talent continues, Arch Systems provides manufacturing and data expertise in its products and services to fill the gap. Beyond storing, standardizing, and pushing data out, they use AI and GenAI to drive actions for improvements on the floor.

Products

The product suite includes the ArchFX platform with connectors to gather, structure, and manage data, an analysis engine to generate insights, and an action manager or copilot for root cause identification, assigning actions, reporting up, and sometimes taking action. On top of the platform sits GLO (Global and Local Operations intelligence) for guided action based on complex production data with real-time monitoring, analytics, and diagnostics on machine data.

A no-code platform at the core enables analysis of the areas that matter most to each customer. The platform data infrastructure is the secret sauce behind this approach to intelligent action. While Arch Systems is an IIoT platform, it doesn’t align with just one software category. Instead, it spans analytics, data management, manufacturing operations, and artificial intelligence. Arch’s products work with many types of manufacturing software like MES, PLM, and ERP.

Incremental Approach

Pick your pain point, address it with the platform and intelligence applications supported by Arch’s experienced staff, and value can ensue quickly. Data from MES, SCADA, machines, and other sources are inputs for the ArchFX platform and applications. As a result, Arch can deliver value with minimal disruption, layering actionable intelligence onto the current environment. Customers have gotten value in weeks, eliminating the need to embark on other IT projects to enable digital transformation.

Arch shows that software can grow seamlessly from one problem area to others and from one plant to many. Depending on company needs, Arch can support a unified data model for an entire global enterprise or focus on just a few products/lines/factories. The company delivers value by focusing on gathering and brokering the data needed to take action on a specific issue for a wide array of people in manufacturing.

Arch shows that software can grow seamlessly from one problem area to others and from one plant to many. Depending on company needs, Arch can support a unified data model for an entire global enterprise or focus on just a few products/lines/factories. The company delivers value by focusing on gathering and brokering the data needed to take action on a specific issue for a wide array of people in manufacturing.

Customers

The company has had great success with electronics contract manufacturers such as Flex, Jabil, and Plexus. They began with a strong focus on high tech manufacturing lines such as surface-mount technology (SMT). The more automated, the more data, and the easier Arch’s AI-based software can get started. Today, Arch Systems supports various discrete manufacturing processes including semiconductor packaging, injection molding, and assembly and test. Other notable public customers include BAE Systems and Harman.

Thank you, Sumana Padmanabhan, for setting up the briefing, and Laura Horvath, for explaining Arch Systems’ current state to me.