How can a strong auditing program, as practiced in major automotive suppliers, improve? By going digital. Ease.io as been doing that for years, with a SaaS software platform for Layered Process Audits (LPAs), 5S, Safety Inspections, Gemba walks, Root Cause Analysis (RCA), and problem-solving. They recently added on-the-job (OTJ) training support to strengthen customers’ outcomes.

Standardizing and Digitalizing Audit Practices

Many lean and operational excellence programs include regular audits. Audits are designed to improve quality, productivity, and safety, and nearly always do. However, using paper, spreadsheets, tribal knowledge, and legacy or homegrown software can create inefficiencies and missed opportunities. For example, if standard processes are not executed consistently or when follow-ups to issues are slow, manufacturing issues can arise and cause problems.

For over 10 years, EASE has been selling software to support these process audit activities. Customers report vastly increased audit completion rates, with up to a 90% reduction in leadtime for major audits. Allowing data to flow smoothly with less administrative burden can help LPA and other audit processes deliver their value with minimal non-value-added overhead.

New Thinking, Digital Support

Manufacturers adopting a digital platform may encounter early resistance from end-users to the change in how audits have been conducted in the past. EASE encourages customers to explore how new technologies enable them to rethink how they do things. Using integrated technology can also help identify all trends and breakdowns. It also helps to trace the root causes of problems and track whether actions have improved the situation.

One of the most significant benefits of a digital approach is the speed to identify and notify about non-conformances. Another is the ability to make audits more effective, consistent, and visible. The digital record also makes it easier to detect when corrective actions have not had the expected impact, to re-address needed issues, and truly close the loop to optimize outcomes.

Supporting Training – A New Level of EASE

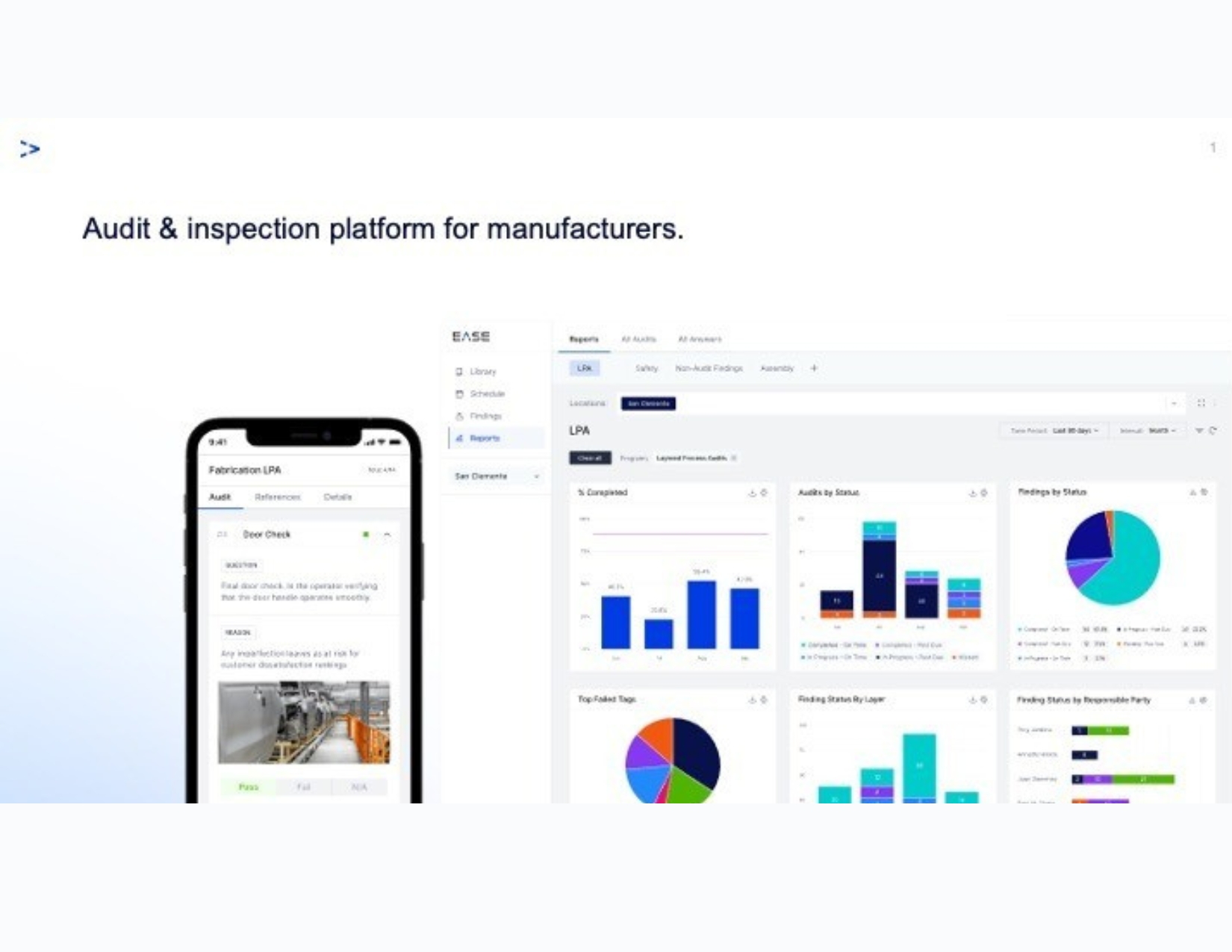

EASE is available as a SaaS subscription. The base audit & inspection version of EASE supports mobile audit and inspection checklist authoring through both pulling existing checklists and creating new ones. It also incorporates automated scheduling, findings management, and real-time data and dashboards for clear visuals of audit results. Naturally, EASE must connect to the systems of record, including QMS, MES, and CMMS. EASE Connect also enables bulk data access for BI tools and dashboarding, while Insights is their own dashboard solution that delivers custom-built dashboards specific to individual customers.

The next Level of EASE subscription includes creation and management of action plans. Action plans support collaborative RCA and analysis to document and facilitate problem investigation and understanding. Here, the EASE solution enables customers to create a library of guided problem-solving processes, milestones, and tasks. Then, the customer sets an action plan based on findings, assigning owners and approvers to each task along with due dates. Finally, this enables monitoring progress and scheduling validation tasks for sustained corrective actions.

A new release from summer 2025 includes OTJ capabilities. In performing corrective actions, EASE saw a way to facilitate training. As operator errors and poor training are shared drivers of non-conformances across the customer base, this became a clear need. Customers generate training from existing documents and publish it as contextual training that is triggered from findings. It can accommodate individual or group training, quiz users, and require sign-offs after training, also checking whether it addressed the issue. With the current “gray tsunami” of knowledgeable workers retiring, this need is only increasing.

Broad Use and Impact

EASE reports that customers have achieved excellent results. These include a 20% decrease in the cost of poor quality, a 2% improvement in OEE, and a 67% decrease in time to close out findings. Better audits and process improvements lead to lower cost of poor quality, higher productivity, and improved labor efficiency.

EASE claims to have over 350 customers using EASE in more than 3,500 plants across 60 countries. Customers are in the automotive, aerospace and defense, furniture, and a range of both process and discrete manufacturing industries. It appears that in these companies, use is also growing, as EASE reports that the platform now supports over four million audits each year.

We look forward to following EASE’s continued progress and growth in the manufacturing markets. Clearly this company Is helping manufacturers rethink and improve their audit processes. Ironically, Julie Fraser met Ease.io at the Manufacturing Leadership Council’s Rethink 2025 event. Thank you, Josh Santo, John Fredrickson, and Andrea Walter, for the briefing!