How can manufacturers improve OEE with IoT Analytics? How can they leverage IoT and IIoT data to drive higher performance and extend the advantages they’ve gained from Six Sigma and other productivity improvement programs? Improving Manufacturing Performance with IoT Analytics takes a look at how to improve Operational Equipment Effectiveness through digitalization. Specifically, the report looks at how analytics can help reduce the Six Big Losses of OEE.

How can manufacturers improve OEE with IoT Analytics? How can they leverage IoT and IIoT data to drive higher performance and extend the advantages they’ve gained from Six Sigma and other productivity improvement programs? Improving Manufacturing Performance with IoT Analytics takes a look at how to improve Operational Equipment Effectiveness through digitalization. Specifically, the report looks at how analytics can help reduce the Six Big Losses of OEE.

Please enjoy the summary below (no charge, no registration required).

For the full report, please visit our sponsor PTC (no charge, registration required).

Improving Productivity Through Digitalization

The Strategic Importance of Digitalization

Digitalization is changing the landscape in manufacturing as companies adopt Industry 4.0, Smart Manufacturing, and Digital Transformation initiatives. In fact, a recent Tech-Clarity survey shows that over one-half of manufacturers believe that digitalization / digital transformation initiatives are “important” if not “critical” to achieving their business strategy.

The Internet of Things (IoT) is a critical component of digitalization in the plant, helping companies connect with production assets to better monitor how they perform. Beyond gathering data, manufacturers can leverage advanced analytics to gain real intelligence about plants and production to improve operations, driver higher performance, and guide continuous improvement.

The Internet of Things (IoT) is a critical component of digitalization in the plant, helping companies connect with production assets to better monitor how they perform. Beyond gathering data, manufacturers can leverage advanced analytics to gain real intelligence about plants and production to improve operations, driver higher performance, and guide continuous improvement.

Justifying IoT Analytics Investments

For some companies, leveraging the Industrial IoT (IIoT) is simply a strategic “must do.” For others, they have to cost justify it. This eBook offers a framework to develop an ROI for IoT investments using a common manufacturing metric, Overall Equipment Effectiveness (OEE).

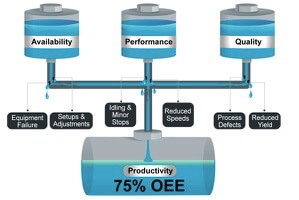

Analyzing improvement potential by OEE allows companies to determine potential savings in the context of the plant. The framework shows how companies can use the IoT and analytics to reduce the “Six Big Losses of OEE” and tangibly improve the three components of OEE – Availability, Performance, and Quality. Manufacturers can compare these improvement opportunities to the investment required to achieve them in order to calculate an ROI.

Next Steps – Getting Started

Develop Your IoT Analytics ROI Using The OEE Framework

Whether you’re trying to grow OEE from the middle of the pack or trying to eek out additional improvements to continuously approach 100%, IoT analytics is a very good option. Companies can use the framework in this eBook to estimate the business value of an IoT analytics initiative based on research and case studies, tailoring the assumptions to fit their business and adding costs to develop an ROI and justify their efforts.

Start Small and Expand

Of course it’s important that companies recognize that they should start small, gain tangible value, and create a foundation to expand on. Early projects should be valuable and measurable with tangible business results, not just technical proofs of concept. They should identify and prioritize opportunities in the plant based on the ability to improve OEE. For example, they can use IoT analytics reduce equipment downtime for a problem workcell or improve yield for a challenging product. At the same time, they should keep costs low and set the foundation for the future by using a scalable, platform-based approach.

Get Started

It’s time to improve productivity by reducing the 6 Big Losses of OEE and driving improvements to Availability, Performance, and Quality. Pick a project and scale up the value by extending to new products, production lines, plants, or geographies. It’s time for manufacturing to drive meaningful change with IoT analytics and set the stage for future improvements beyond the plant. Remember, a small improvement to OEE can drive significant bottom line results, and the foundation created by Manufacturing can open up new business models and revenue opportunities across the business.

*This summary is an abbreviated version of the report and does not contain the full content. A link to download the full report is available above.

If you have difficulty obtaining a copy of the report, please contact us using the “Contact” link below.