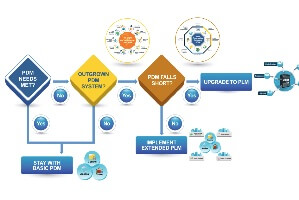

What should manufacturers look for when they’ve outgrown PDM and need to “level up” to PLM? Product Data Management (PDM) is a critical capability for a manufacturer of any size. As our research shows, PDM helps companies achieve business benefits including increased efficiency, improved quality, reduced cost, and the ability to bring products to market much faster. At some point, however, most manufacturers find that their PDM system falls short of their growing needs. They face a decision to either upgrade to a more capable PDM system or “level up” to a broader PLM solution. How can they tell which direction is right for their business? What should they look for in a replacement PDM or a PLM solution?

What should manufacturers look for when they’ve outgrown PDM and need to “level up” to PLM? Product Data Management (PDM) is a critical capability for a manufacturer of any size. As our research shows, PDM helps companies achieve business benefits including increased efficiency, improved quality, reduced cost, and the ability to bring products to market much faster. At some point, however, most manufacturers find that their PDM system falls short of their growing needs. They face a decision to either upgrade to a more capable PDM system or “level up” to a broader PLM solution. How can they tell which direction is right for their business? What should they look for in a replacement PDM or a PLM solution?

This eBook explains how to recognize that you’ve outgrown PDM and offers several options to find the data and process management capabilities your company needs, whether it’s time to find a more capable PDM or upgrade to PLM. It also provides practical advice on what to look for in a PLM solution, to ensure a successful implementation, and in a software partner.

Please enjoy the summary below. For the full Buyer’s Guide, please visit our sponsor PTC (registration required).

Please also see our related Expanding Beyond Your Outgrown PDM Systems Buyer’s Guide which shares the top ten signs you’ve outgrown your PDM system and what to look for in a more capable data management solution.

Table of Contents

- What to do When Your PDM is No Longer Enough

- A Guide for Upgrading from PDM to PLM

- Recognizing When the Time has Come for PLM

- When You’ve Outgrown Your PDM

- Path 1: A More Capable PDM

- Path 2: Upgrading to PLM

- What to Look for to go Beyond PDM to PLM

- 1) Manage the Whole Product

- 2) Support Product Development Processes

- 3) Expand Support of the Lifecycle

- 4) Extend to more People, Departments, and Roles

- 5) Integrate PLM into the Systems Ecosystem

- New Service and Vendor Considerations

- Special Considerations

- Next Steps

- Acknowledgments

A Guide for Upgrading from PDM to PLM

The Purpose of this Guide

Like all of our buyer’s guides, this eBook is intended to help manufacturers make the right decision when they select a new solution. When companies need to move beyond their current PDM, the information in this guide will help them choose the right course of action. It complements our Expanding Beyond Your Outgrown PDM System guide that explains how to move from a basic PDM system to a more capable PDM solution.

Understanding the Structure of the Guide

The guide focuses on how to know it’s time for PLM, where to find PLM requirements, and some key things to look for in order to achieve the most value from the transition. The guide covers functional requirements, but also highlights what’s needed for successful implementation, adoption, and support. It also puts forward criteria to identify the right vendor partner.

References to Other Buyer’s Guides

This guide doesn’t repeat requirements covered in our existing PDM and PLM guides, including guides for selecting basic or Extended PDM systems. Those guides already share the key requirements that we’ve found make a difference in achieving desired value. In order to prevent duplication, this guide references the others to help companies gather requirements to help manufacturers quickly identify the solutions to evaluate more closely.

Recognizing When the Time has Come for PLM

When PDM Capabilities Aren’t Enough

The PDM Buyer’s Guide encourages manufacturers to “consider future needs” and “build a foundation to grown on” when they select a PDM system. Sometimes that advice wasn’t followed. Other times, business circumstances dictated implementing a less capable solution.

But more often, a solution that fulfilled company needs at a certain point in time just isn’t enough anymore due to:

But more often, a solution that fulfilled company needs at a certain point in time just isn’t enough anymore due to:

- Product complexity

- Product development complexity

- Growth

- Globalization

- Outdated software

- Increased product innovation maturity

- The need to achieve value beyond product development

- The need to support digital transformation

The Time is Right to Evaluate PLM

Whatever the reason companies hit a dead end with their PDM solution, it’s time to make a change. But before moving to a new PDM, it’s prudent to consider if a more advanced PDM system will be enough. Even if companies feel they aren’t ready for PLM and choose to move to an Extended PDM system, we recommend considering the PDM components of a modular Product Innovation Platform that gives them a path to add the capabilities they need as their needs grow and their processes mature.

Making Sure that PLM Stands the Test of Time

In the same way, it’s important to incorporate requirements to support digital transformation when looking for a new system. PLM is the digital product backbone for the manufacturing enterprise. Even if a manufacturer isn’t ready to adopt a digital model, it’s important to choose a solution that will support that eventual transition.

Next Steps

Leverage PDM Investments to Increase Value

Leverage PDM Investments to Increase Value

Companies that have outgrown PDM can leverage their existing investment to take advantage of broader PLM benefits. The value is proven. Top Performing companies are more likely to have structured, collaborative systems like a more mature PDM or a PLM system. While PDM is often a productivity tool, PLM can drive new business value by helping to drive top-line growth.

Create a Foundation for Further Growth

As companies adopt a PLM system, it’s important to leave room to expand to more mature capabilities over time. Mature PLM systems support a variety of business processes and initiatives that translate to both top-line and bottom-line benefits. In addition, PLM scope continues to grow and expand to provide even more capabilities.

Consider a Platform for the Greatest Potential Value

We recommend that companies evaluate an integrated Product Innovation Platform (PIP) when moving to PLM. A PIP offers manufacturers the ability to expand from PDM today and create room to grow as they are ready to adopt more, or more mature, processes. A PIP with a modular approach will allow them to scale and add capabilities as they need them.

Final Words: Don’t Forget the Future

Finally, no company should select a solution without considering the cloud or digital transformation. PLM plays a vital role as the backbone of the digital manufacturing enterprise. In addition, cloud PLM solution adoption continues to increase. To ignore the realities of these two trends would be shortsighted.

*This summary is an abbreviated version of the report and does not contain the full content. A link to download the full report is available above.

If you have difficulty obtaining a copy of the report, please contact us using the “Contact” link below.