A quick peek into some research on designing and developing industrial equipment. The report, Tech-Clarity Perspective: Best Practices for Developing Industrial Equipment analyzes the performance of well over 300 manufacturers in order to determine what the top performers do differently than the rest. The results are pretty exciting!

A quick peek into some research on designing and developing industrial equipment. The report, Tech-Clarity Perspective: Best Practices for Developing Industrial Equipment analyzes the performance of well over 300 manufacturers in order to determine what the top performers do differently than the rest. The results are pretty exciting!

Note: You can also see a related article Product Design Strategies Take Manufacturers to the Top by Travis Hessman in IndustryWeek.

The Research Approach

I will keep this brief. The report focuses determining two primary things:

- Which of the survey respondents are performing better financially?

- What are those companies doing different operationally?

Why do this? Because we want to help everybody reach higher levels of performance!

The Research Findings

After writing about how engineering can help companies survive a down economy for a while it is nice to share some good news. On average, the respondents to our survey have grown both their top line and their profit margins over the last two years. You would argue that tells us more about how bad it was three years ago than how good things are today, but the fact is things have gotten better.

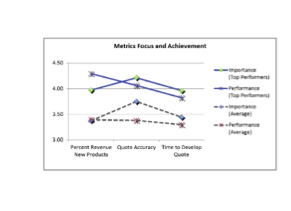

But… they have gotten “more better” for some companies than others.  Twice as good, in fact. Specifically, we asked companies to rate and then quantify their financial performance and identified a top level of performers we called the “top performers.” The table clearly shows how much better they have performed over the last two years.

Twice as good, in fact. Specifically, we asked companies to rate and then quantify their financial performance and identified a top level of performers we called the “top performers.” The table clearly shows how much better they have performed over the last two years.

That isn’t the exciting part. What is exciting is that we observed different design approaches and technologies in the top performers. These approaches can serve as best practices for other industrial equipment companies. What did these companies do differently? They were much more likely to:

- Use rules-based design approaches

- Develop a single, global product

- Leverage platform design techniques

- Use modular design approaches

Although they used many of the same design tools as others (most use 3D CAD, for example), they are likely using them in more advanced ways to support the processes mentioned above. In addition, there were certain enabling technologies they used more frequently than others, including:

- Simulation

- Product configurations / design automation

- PLM

- Factory layout / simulation tools

Implications for Manufacturers

What does this mean to manufacturers? For industrial equipment producers (and others that produce similar products) it means that you can improve your performance by taking your design processes and technology to the next level. Taking more disciplined engineering approaches can reap large rewards. One surprising – and important – advantage that the top performers have is the ability to develop more accurate quotes (see the paper for more insight on this topic, it’s pretty eye opening).

So that was a quick peek into some recent research on designing industrial equipment, I hope you found it interesting. Does the research reflect your experiences? Do you see it differently? Let us know what it looks like from your perspective.

Please feel free to review more free research and white papers about PLM and other enterprise software for manufacturers from Tech-Clarity.