Siemens Support for Service Exceeded Our Expectations

It’s our goal as analysts to stay informed about the software solutions available on the market and how they drive business value for manufacturers. We do this by conducting surveys, speaking with manufacturers, attending events, and taking briefings from solution providers. One of the things that excites us the most is when we learn something new. Recently, we learned that we were underestimating Siemens Digital Industries Software Service Lifecycle Management (SLM) capabilities. We thought it was worth sharing.

Deep Support for Product and Service Data

One of the primary ways that Product Lifecycle Management (PLM) solutions can help add value in a device or equipment’s service phase is by providing technical data downstream. Engineering data is highly valuable to service planners, techs, and other support personnel. We were aware of the capabilities Siemens delivers in this area based on prior conversations and briefings. Siemens understands how products are designed, made, and serviced.

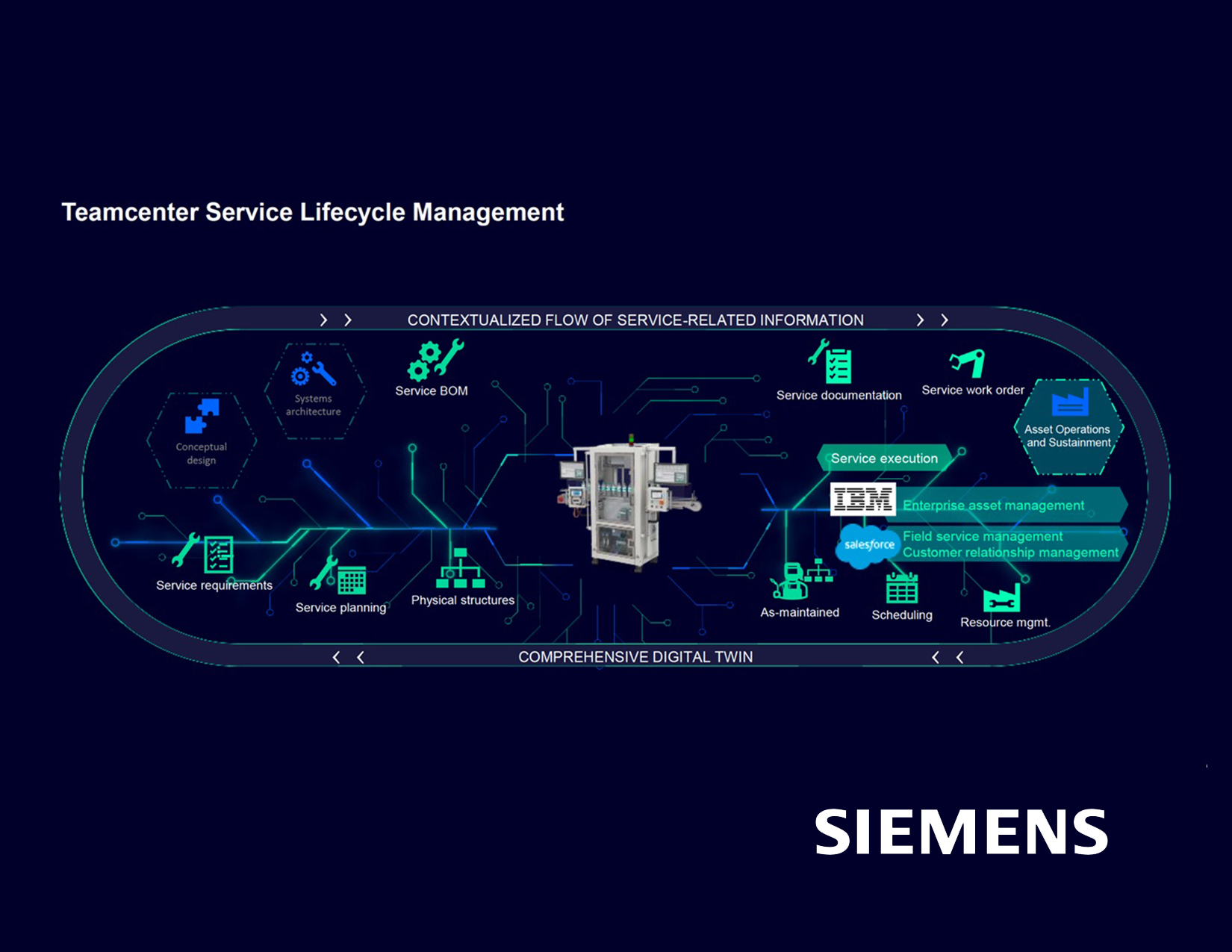

Siemens Teamcenter is a proven PLM solution and Teamcenter SLM has matured nicely over the years. Siemens followed a natural expansion beyond engineering and manufacturing BOMs to support the service BOM. We’ve seen how Teamcenter manages multidisciplinary data across product lifecycles and know it can manage complex configurations for both standard and engineer-to-order (ETO) products. Teamcenter’s ability to manage variants, revisions, and changes for serialized assets creates valuable product intelligence for service-related processes.

Teamcenter’s capabilities in both PLM and SLM also create an opportunity for customers to close the loop from service back to engineering. An integrated view of service and product data allows engineers better visibility downstream so they can better design for service and quality based on real-world feedback.

Supporting the Service Lifecycle

We knew that Teamcenter SLM was a strong source of product- and service-related data and recognized that this underlying information is crucial to effective service. Our research shows the value of extending PLM data into the “in use” phase of the lifecycle. Integrating design and service information provides even greater business value, as shown in our recent infographic on integrated service. The combination of product and service intelligence to support service transformation is compelling. As our Extending Digital Thread to the Customer Experience research shares the value of integrating the digital thread across the development and service lifecycles allows companies to develop a more intimate understanding of the customer and product experience and create new value from increasing profitability with lower costs and higher revenue from spares, suppliers, upgrades, replacements, and cross-selling opportunities.

We knew that Teamcenter SLM was a strong source of product- and service-related data and recognized that this underlying information is crucial to effective service. Our research shows the value of extending PLM data into the “in use” phase of the lifecycle. Integrating design and service information provides even greater business value, as shown in our recent infographic on integrated service. The combination of product and service intelligence to support service transformation is compelling. As our Extending Digital Thread to the Customer Experience research shares the value of integrating the digital thread across the development and service lifecycles allows companies to develop a more intimate understanding of the customer and product experience and create new value from increasing profitability with lower costs and higher revenue from spares, suppliers, upgrades, replacements, and cross-selling opportunities.

Teamcenter SLM goes further than providing existing data by expanding beyond engineering data to information like service procedures. Not only can the solution manage and share this information, their Tech Pubs/RapidAuthor solution leverages design models and data to develop accurate, 3D technical documentation including visual and animated service instructions.

Product Support Data Management (PSDM)

Product Support Data Management (PSDM)

One specific way Siemens drives value is with its Product Support Data Management (#PSDM) solution. PSDM is a standards-based approach to documenting product support requirements tied to specific asset configurations. The solution brings together product lifecycle and logistics support data, leveraging the standard GEIA-STD-0007. The standard originated from the military to support government contracts but is applicable across a variety of industries. Siemens adopted this standard and incorporated it in the Teamcenter data model to support maintenance and logistics related data imports and exports.

Siemens Partners to Support Sales and Service Execution

Beyond sharing information, our research points out the value of strong sales and service execution support. Manufacturing and service companies must improve and optimize the processes supporting sales and service operations to grow their aftermarket business. Sales and service transformation requires convergence across people, processes, data, and systems in the engineering and enterprise systems. Customer interactions, spare parts, service contracts, warranty entitlements, and other service complexities are managed in solutions like CRM, Field Service Management, Enterprise Asset Management (EAM), and even ERP. Siemens’ customers can integrate with these systems, but that doesn’t create a seamless process.

This is where our understanding of Siemens’ capabilities needed to expand. Siemens has been working to bridge the gap between design, service planning, and service execution. They now support the front office, sales teams, customer service, and even equipment operators through strong partnerships. This brings the value of SLM to the front office while keeping it tied into Teamcenter PLM to extend the value of rich digital data beyond the engineering population, in the right context, to enable execution processes. Siemens is not trying to recreate what field service and CRM solutions do, but instead make them more valuable by providing a more complete solution to their customers by connecting with them.

This is where our understanding of Siemens’ capabilities needed to expand. Siemens has been working to bridge the gap between design, service planning, and service execution. They now support the front office, sales teams, customer service, and even equipment operators through strong partnerships. This brings the value of SLM to the front office while keeping it tied into Teamcenter PLM to extend the value of rich digital data beyond the engineering population, in the right context, to enable execution processes. Siemens is not trying to recreate what field service and CRM solutions do, but instead make them more valuable by providing a more complete solution to their customers by connecting with them.

Siemens now supports cohesive processes and a consistent digital thread from engineering through field services and sales. Siemens was able to leverage their open approach and rich APIs in their platform to support a variety of partnerships. These partnerships include IBM Maximo Application Suite for EAM and Salesforce for CRM. In both of these cases, Siemens focuses on the product data and service knowledge, not the customer data and service execution. This is exciting news, and we were happy to hear that Teamcenter SLM for Salesforce has been available on the Salesforce AppExchange for about a year. The Salesforce partnership also opens up Teamcenter’s product and service data to Agentforce, Salesforce’s AI offering, unlocking significant new opportunities to leverage the cohesive digital thread.

Example

Siemens demonstrated an example of how combining an integrated PLM-CRM environment with AI can streamline and improve customer experience, service performance, and profitability. They showed how Agentforce could be deployed on an equipment manufacturer’s website. A customer can visit the site and enter an asset name and serial number, which would be interpreted to create a draft case for review, combining details about the configuration, including product information like 3D visuals, service data like detailed service instructions, and business data such as warranty terms in one place. They went further to show how the combined, AI-enabled solution could identify additional opportunities like a service upgrade based on the combined data. It was a compelling view of an end-to-end integrated process.

Our Take

Siemens has a lot to offer across the product and service lifecycle through the Siemens Xcelerator portfolio and their partnerships. Siemens’ value in SLM goes beyond product data and service knowledge to service execution, enabling an integrated digital thread. The offering extends on Siemens’ deep expertise and strength in PLM and their open platform approach. Together with their partners, they have developed a very compelling offering spanning the product and service lifecycle. If you haven’t seen it in a while, it’s worth a deeper look. We learned quite a bit.

Thank You

Thank you for the briefing Kerri Doyle, Brian Johnsen, Dominique Gilles, Yishai Barak, and Rajvi Vaidya for taking the time for the briefings, we appreciate your time.