Driving Engineer-to-Order Differentiation and Profitability, Analyzing Trends and Best Practices in Product Configuration shares survey findings and interviews with leading manufacturers showing how Top Performers achieve higher revenue and profit margin growth through ETO best practice processes and technology. The research shares results of a survey of over 200 manufacturers and analyzes their use of product configurators and automation technology to improve estimation, quote, design, documentation, and manufacturing performance.

shares survey findings and interviews with leading manufacturers showing how Top Performers achieve higher revenue and profit margin growth through ETO best practice processes and technology. The research shares results of a survey of over 200 manufacturers and analyzes their use of product configurators and automation technology to improve estimation, quote, design, documentation, and manufacturing performance.

Click here for the full report, thank you to our sponsor Siemens PLM.

Executive Overview

Customized products are more compelling to customers and drive higher profitability. They can also create chaos in sales proposal and order fulfillment processes as engineers scramble to develop cost estimates, customized designs, and detailed manufacturing and sales documentation. This engineer-to-order (ETO) study finds that some companies have found better ways to design custom products, alleviating the engineering bottleneck created in most companies when quotes requests or orders roll in.

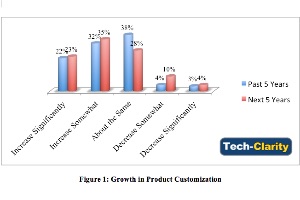

The manufacturing industry needs to adopt best practices and technology to accommodate the growth in customized products. Researchers for this report surveyed over 200 companies, finding that product customization is growing significantly. Why? For some companies, it helps them differentiate. For others, their industry doesn’t give them a choice. It’s just the nature of the business. Either way, growth in product customization drives increased complexity that leads to late deliveries, recalls / warranty work, and missed financial targets. The cause? Manual processes for custom products make Engineering a bottleneck to getting quotes and orders out of the door.

Fortunately Tech-Clarity research1 shows that companies taking more advanced ETO approaches to customize their products end up with better results. This report investigates trends in customization and digs deeper into these best practices. The analysis finds that manufacturers achieving the highest sales and profitability growth, The Top Performers, place more strategic emphasis on rapid quote and order turnaround. They also perform better when executing orders, experiencing significantly fewer errors.

Our research shows that Top Performers adopt leading design practices including platform, modular, and rules-based design techniques1. Survey reports show they support these best practices with leading technologies, finding that they are:

- More than twice as likely to use technical product configurators

- 53% more likely to have quote automation

- 22% more likely to leverage design automation

This research concludes that customization performance can be improved with ETO best practices and technologies. These approaches help Top Performers relieve engineering bottlenecks, leading to better order performance and financial results.

Table of Contents

- Executive Overview

- Product Customization is on the Rise

- Understanding Customization Business Drivers

- Creating Differentiation in Customized Products

- Taking A Deeper Look at Customization

- Recognizing Customization Challenges

- Recognizing Potential Negative Impacts of Customization

- Identifying the Top Performers

- Analyzing what Top Performers do Differently

- Evaluating Top Performers’ Process Advantages

- Analyzing the Technical Enablers of Top Performers

- Identifying the Technical Capabilities of Top Performers

- Conclusion

- Recommendations

- About the Author

- About the Research

- Footnote

Conclusion

Product customization is growing and is expected to continue to grow. Customization provides significant business value, but also brings significant challenges. These challenges result in a large percentage of orders with costly and time-consuming mistakes. Top Performers, however, have fewer order errors than others. One of the key differences between their approaches and the Others’ is that they have adopted more engineering automation. ETO automation helps eliminate engineering bottlenecks and manual processes that lead to delays and errors. “If it’s done right, engineering becomes a nonfactor for leadtimes,” explains Price Mechanical’s Rogers.

Product customization is growing and is expected to continue to grow. Customization provides significant business value, but also brings significant challenges. These challenges result in a large percentage of orders with costly and time-consuming mistakes. Top Performers, however, have fewer order errors than others. One of the key differences between their approaches and the Others’ is that they have adopted more engineering automation. ETO automation helps eliminate engineering bottlenecks and manual processes that lead to delays and errors. “If it’s done right, engineering becomes a nonfactor for leadtimes,” explains Price Mechanical’s Rogers.

Some of the key enablers that Top Performers employ more than Others are technical product configurators, design automation, MBOM generation, quote generation, and CAD automation. “The whole idea is to automate a process to allow someone to do something more value-added for the business,” explains Mark Rogers of Price Mechanical. “Automation allows engineers to design new things or cost-down products instead of processing orders.” These technologies help relieve the engineering bottleneck for customized orders and are likely the source of Top Performers enhanced order execution and higher financial performance. Other commonly used technologies including CAD, sales (CPQ) configurators, ERP, and spreadsheets also provide value, but they aren’t correlated with the Top Performers’ better performance.

Recommendations

Based on industry experience and research for this report, Tech-Clarity offers the following recommendations:

- Focus on speed as a differentiator for customized products

- Adopt modular and platform design approaches to streamline customization

- Recognize the different capabilities of Technical Product Configurators and Sales (CPQ) Configurators, using each for their strengths (and possibly in combination)

- Leverage technical product configurators and design automation to remove manual engineering effort that creates bottlenecks and results in errors in sales and order engineering processes

Adopt MBOM and quote generation capabilities to improve custom order performance