How can manufacturers accelerate equipment quotes, design, and delivery without sacrificing performance and quality? What four disciplines do they need to digitally transform their design processes to move faster and get designs right the first time despite increasing complexity? Please enjoy the summary* below. For the full research, please visit our sponsor Siemens (registration required). For…

Design Automation

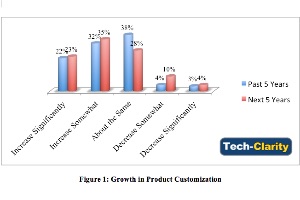

Driving Engineer-to-Order Differentiation and Profitability (survey findings)

Driving Engineer-to-Order Differentiation and Profitability, Analyzing Trends and Best Practices in Product Configuration shares survey findings and interviews with leading manufacturers showing how Top Performers achieve higher revenue and profit margin growth through ETO best practice processes and technology. The research shares results of a survey of over 200 manufacturers and analyzes their use of…

Optimizing the Bidding Process

Optimizing the Bidding Process: How Industrial Equipment Manufacturers Can Win More Business focuses on the importance of getting the bidding process right. Bids require a quick response, yet must be competitively priced, without sacrificing margins. Getting this right is a challenge for many companies, but is especially difficult for businesses such as industrial equipment manufacturers offering Engineer-to-Order…

Improving Profitability for Configured Products

Improving Profitability for Configured Products: Leveraging Sales Configuration and Design Automation explores how companies can profitability tailor products to meet customer needs. The research investigates the experiences of several companies, revealing several key areas companies should focus on to improve their profitability. Please enjoy the summary below, or click the report to download a PDF overview (free…

Webcast Driving a Competitive Edge Through Customization

Jim Brown joins Mark Rogers of Price HVAC and Rick Smith of Siemens PLM to discuss how to improve ETO processes and performance. Jim will share findings from a recent survey on what strategies, best practices, and enabling technologies top performing manufacturers use to gain higher profits from their customized products. Register now (free of charge, registration required)…

Product Configuration and “To Order” Manufacturing Survey

How do leading “to order” manufacturers support their sales, quote, and manufacturing processes? The survey is closed, thank you. Thank you for your help and support! Rules To be eligible for this offer, you must complete the survey and be a professional with job responsibilities related to or supporting the development, release, or manufacture of…