Jim Brown contributed a post to the Autodesk Fusion Connect site sharing the Top Five Factors for a Successful Industrial IoT Implementation. The post provides an introduction to our Ten Build-Buy Factors for IoT Platforms eBook tailored to Engineers so they can understand not only how to support their company’s IoT initiative, but also how to gain…

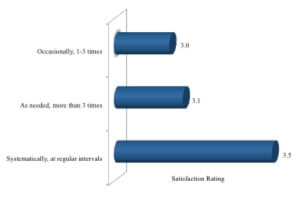

- The top improvement areas you should focus on to get even more value from simulation

- Best practices followed by Top Performing companies to overcome simulation bottlenecks

- Selection criteria to help you identify the right simulation solution for your company

[post_title] => Addressing Bottlenecks in Simulation (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => webinar-simulation-bottlenecks

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:52

[post_modified_gmt] => 2022-11-15 03:26:52

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5684

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[5] => WP_Post Object

(

[ID] => 5652

[post_author] => 2

[post_date] => 2016-09-19 09:13:57

[post_date_gmt] => 2016-09-19 13:13:57

[post_content] =>

[post_title] => Addressing Bottlenecks in Simulation (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => webinar-simulation-bottlenecks

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:52

[post_modified_gmt] => 2022-11-15 03:26:52

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5684

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[5] => WP_Post Object

(

[ID] => 5652

[post_author] => 2

[post_date] => 2016-09-19 09:13:57

[post_date_gmt] => 2016-09-19 13:13:57

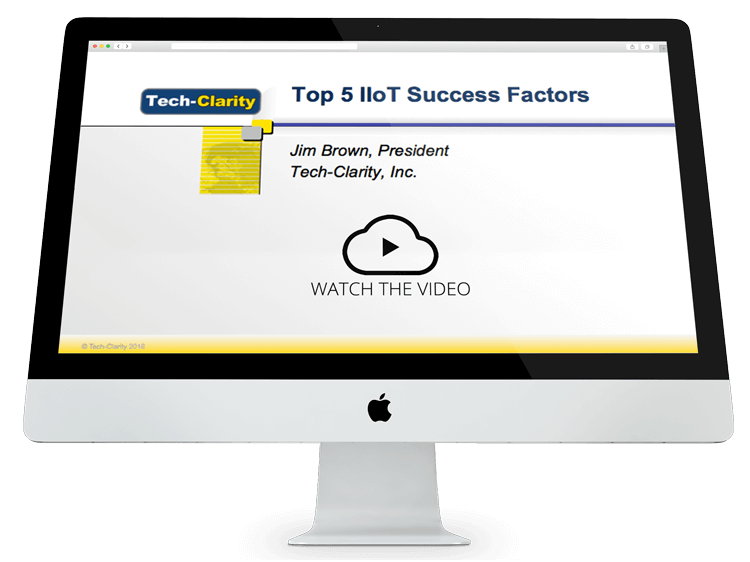

[post_content] =>  Jim Brown presented his recent research on building versus buying IIoT infrastructure in the upcoming Top 5 Factors for a Successful Industrial IoT Implementation webcast on Engineering.com (sponsored by Autodesk). The webcast also featured Autodesk's Head of IoT, Bryan Kester, sharing how IIoT can help improve product service, close the loop on engineering designs, and create new revenue streams.

Watch the Recorded Webcast. (free of charge, registration required)

Jim Brown presented his recent research on building versus buying IIoT infrastructure in the upcoming Top 5 Factors for a Successful Industrial IoT Implementation webcast on Engineering.com (sponsored by Autodesk). The webcast also featured Autodesk's Head of IoT, Bryan Kester, sharing how IIoT can help improve product service, close the loop on engineering designs, and create new revenue streams.

Watch the Recorded Webcast. (free of charge, registration required)

[post_title] => Top Five Five Factors for a Successful IIoT Implementation (webcast replay)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => iiot-top5

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:44

[post_modified_gmt] => 2022-11-15 03:26:44

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5652

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[6] => WP_Post Object

(

[ID] => 5668

[post_author] => 2572

[post_date] => 2016-09-15 09:25:05

[post_date_gmt] => 2016-09-15 13:25:05

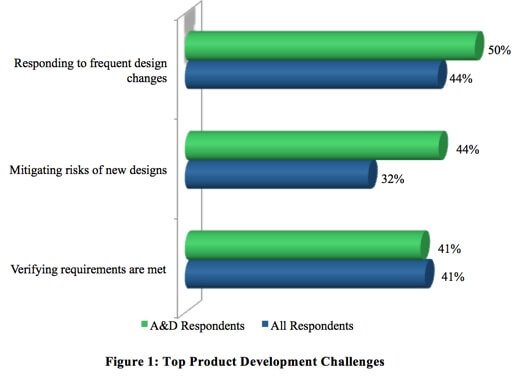

[post_content] => How Aerospace and Defense (A&D) Companies Get More Value from Simulation is a new Siemens guest post. In this post, Michelle Boucher explores how A&D companies use simulation. The post highlights challenges faced by A&D companies and then shares survey results revealing some of the top ways A&D solve them.

Read the post on the Siemens Femap Blog.

The results shared in this blog post came from our recent study, Addressing the Bottlenecks of FEA Simulation You can also hear more about this study at an upcoming webinar on Thursday, September 29, 2016 at 2:00 PM ET/ 11:00 AM PT.

[post_title] => Top Five Five Factors for a Successful IIoT Implementation (webcast replay)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => iiot-top5

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:44

[post_modified_gmt] => 2022-11-15 03:26:44

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5652

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[6] => WP_Post Object

(

[ID] => 5668

[post_author] => 2572

[post_date] => 2016-09-15 09:25:05

[post_date_gmt] => 2016-09-15 13:25:05

[post_content] => How Aerospace and Defense (A&D) Companies Get More Value from Simulation is a new Siemens guest post. In this post, Michelle Boucher explores how A&D companies use simulation. The post highlights challenges faced by A&D companies and then shares survey results revealing some of the top ways A&D solve them.

Read the post on the Siemens Femap Blog.

The results shared in this blog post came from our recent study, Addressing the Bottlenecks of FEA Simulation You can also hear more about this study at an upcoming webinar on Thursday, September 29, 2016 at 2:00 PM ET/ 11:00 AM PT.

[post_title] => How A&D Companies Get More Value from Simulation - Guest Post on Siemens Blog

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => aandd-simulation-siemens-guest-post

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:04

[post_modified_gmt] => 2022-11-15 03:26:04

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5668

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[7] => WP_Post Object

(

[ID] => 5658

[post_author] => 2

[post_date] => 2016-09-15 07:00:06

[post_date_gmt] => 2016-09-15 11:00:06

[post_content] =>

[post_title] => How A&D Companies Get More Value from Simulation - Guest Post on Siemens Blog

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => aandd-simulation-siemens-guest-post

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:04

[post_modified_gmt] => 2022-11-15 03:26:04

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5668

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[7] => WP_Post Object

(

[ID] => 5658

[post_author] => 2

[post_date] => 2016-09-15 07:00:06

[post_date_gmt] => 2016-09-15 11:00:06

[post_content] =>  Tech-Clarity's Jim Brown joined Arena Solutions' Ann McGuire on a TechBriefs webcast about avoiding product launch failures. Jim and Ann discussed why products fail and what companies are doing to improve product development success across the product lifecycle. The webcast, Avoid Product Launch Failure: Best Practices for Aligning Your Engineering and Quality Teams, is sponsored by Arena Solutions.

Watch the recorded event now (free of charge, registration required).

Tech-Clarity's Jim Brown joined Arena Solutions' Ann McGuire on a TechBriefs webcast about avoiding product launch failures. Jim and Ann discussed why products fail and what companies are doing to improve product development success across the product lifecycle. The webcast, Avoid Product Launch Failure: Best Practices for Aligning Your Engineering and Quality Teams, is sponsored by Arena Solutions.

Watch the recorded event now (free of charge, registration required).

[post_title] => Avoid Product Launch Failure by Aligning Quality and Engineering (webcast replay)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => npd-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:44

[post_modified_gmt] => 2022-11-15 03:26:44

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5658

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[8] => WP_Post Object

(

[ID] => 5632

[post_author] => 2

[post_date] => 2016-09-14 11:12:26

[post_date_gmt] => 2016-09-14 15:12:26

[post_content] => Jim Brown contributed his views on integrating Product Innovation Platforms / PLM to ERP in a recent guest post for Cideon Software. The post pays specific attention to how to integrate the 3DEXPERIENCE platform with SAP. The post shares the increasing importance of integration, the need for a repeatable approach, and some key considerations about finding a partner to help with the complexities of the integration.

Please read the full post on the Cideon Software site (free of charge, no registration required).

http://www.cideon.eu/3dx/best-practices/

[post_title] => Integrating Dassault Systemes' 3DEXPERIENCE Platform with SAP ERP (guest post)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => 3dx-sap

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:32

[post_modified_gmt] => 2022-11-15 03:25:32

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5632

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 1

[filter] => raw

)

[9] => WP_Post Object

(

[ID] => 5625

[post_author] => 2572

[post_date] => 2016-09-08 22:38:58

[post_date_gmt] => 2016-09-09 02:38:58

[post_content] => In a new Siemens guest post, What Is an Optimized Product Design? Michelle Boucher discusses how companies use simulation to optimize their products. However, the term optimization came be a bit vague as it means different things to different people. To clarify the term, this post shares additional data from our recent study, Addressing the Bottlenecks of FEA Simulation defining what engineers are actually trying to do when they optimize their designs.

Read the post on the Siemens Femap Blog.

[post_title] => Avoid Product Launch Failure by Aligning Quality and Engineering (webcast replay)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => npd-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:44

[post_modified_gmt] => 2022-11-15 03:26:44

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5658

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[8] => WP_Post Object

(

[ID] => 5632

[post_author] => 2

[post_date] => 2016-09-14 11:12:26

[post_date_gmt] => 2016-09-14 15:12:26

[post_content] => Jim Brown contributed his views on integrating Product Innovation Platforms / PLM to ERP in a recent guest post for Cideon Software. The post pays specific attention to how to integrate the 3DEXPERIENCE platform with SAP. The post shares the increasing importance of integration, the need for a repeatable approach, and some key considerations about finding a partner to help with the complexities of the integration.

Please read the full post on the Cideon Software site (free of charge, no registration required).

http://www.cideon.eu/3dx/best-practices/

[post_title] => Integrating Dassault Systemes' 3DEXPERIENCE Platform with SAP ERP (guest post)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => 3dx-sap

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:32

[post_modified_gmt] => 2022-11-15 03:25:32

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5632

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 1

[filter] => raw

)

[9] => WP_Post Object

(

[ID] => 5625

[post_author] => 2572

[post_date] => 2016-09-08 22:38:58

[post_date_gmt] => 2016-09-09 02:38:58

[post_content] => In a new Siemens guest post, What Is an Optimized Product Design? Michelle Boucher discusses how companies use simulation to optimize their products. However, the term optimization came be a bit vague as it means different things to different people. To clarify the term, this post shares additional data from our recent study, Addressing the Bottlenecks of FEA Simulation defining what engineers are actually trying to do when they optimize their designs.

Read the post on the Siemens Femap Blog.

Tech-Clarity's research report, Composites State of the Market: Using Composites as a Competitive Advantage, examines survey findings on material trends and composites. Over 240 companies participated in the survey. The research finds that new materials are a significant source of product complexity. The research also finds that of new materials, composites in particular, will see a lot of growth. However, there are engineering knowledge gaps when using composites. The report highlights how Top Performing companies supplement their engineering knowledge so that they can successfully develop and produce composite parts.

Please enjoy the summary below or click the report to download a PDF overview (free of charge, no registration required).

For more research on composites, check out our new survey for A&D companies.

For the full report, please visit our sponsor Siemens PLM (free of charge, no registration required).

Tech-Clarity's research report, Composites State of the Market: Using Composites as a Competitive Advantage, examines survey findings on material trends and composites. Over 240 companies participated in the survey. The research finds that new materials are a significant source of product complexity. The research also finds that of new materials, composites in particular, will see a lot of growth. However, there are engineering knowledge gaps when using composites. The report highlights how Top Performing companies supplement their engineering knowledge so that they can successfully develop and produce composite parts.

Please enjoy the summary below or click the report to download a PDF overview (free of charge, no registration required).

For more research on composites, check out our new survey for A&D companies.

For the full report, please visit our sponsor Siemens PLM (free of charge, no registration required).

Executive Overview

Today’s products are growing in complexity and new materials are a significant source of that complexity. Composites, in particular, are getting a lot of attention. In fact, the use of composites is growing and is expected to increase over the next 15 years. With this growth, the number of engineers working with composites should also increase by 15% over the next five years. Complicating this, even engineers currently working with composites rate their knowledge of composites as average. The combination of complexity, growth in composite use, and increase in the number of engineers using composites means companies will need better ways to supplement their engineering knowledge of composites. Composites have been key for helping many companies differentiate their products by reducing weight, improving performance, and lowering the cost of ownership. However, with the expense of composite material, companies must find ways to make better decisions to optimize the amount of composite material used to achieve performance requirements, without over-engineering and maintaining profitability. To understand best approaches, Tech-Clarity surveyed 244 companies to identify their goals for composites, best practices, and top selection criteria for technology. Further analysis identified how Top Performing companies address the top challenges of designing and producing composite parts. Top Performing companies are those who are more successful than their competitors. Compared to competitors, they are more efficient, faster, produce higher quality products, and do a better job meeting cost targets. When compared to peers, some of the things Top Performers do to achieve this success includes:- 2.2 times more likely to optimize the part design to improve consistency during production

- 59% more likely to use tools that automatically link design and analysis data

- 2.5 times more likely to use tools that automatically update the composite definition as changes are implemented

Table of Contents

- Executive Overview

- Identify the Meaning of Complexity

- Prepare for Growth in Composites

- Realize Opportunities with Composites

- Address Challenges

- Identifying Top Performers

- Understand Production Requirements

- Support Design Decisions

- Select the Right Technology

- Conclusion

- Recommendations

- About the Research

- About the Author

[post_title] => How Simulation Solves Some of Today’s Top Product Development Challenges - Guest Post on Siemens Blog

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => simulation-solves-todays-top-product-development-challenges-guest-siemens-blog

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:01

[post_modified_gmt] => 2022-11-15 03:26:01

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5605

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[13] => WP_Post Object

(

[ID] => 5593

[post_author] => 2572

[post_date] => 2016-08-18 11:43:33

[post_date_gmt] => 2016-08-18 15:43:33

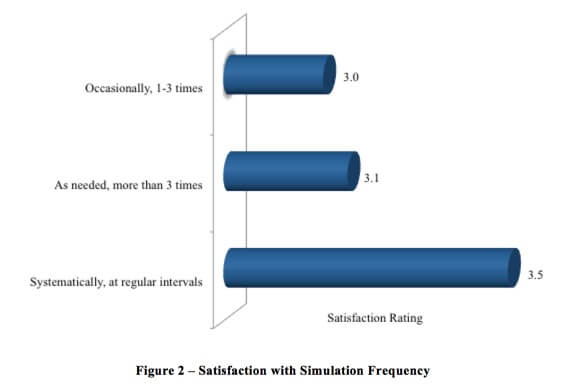

[post_content] => Michelle Boucher shares new research on simulation in this Siemens guest post, Announcing New Research on FEA Simulation Bottlenecks. Simulation can be a powerful tool to help guide design decisions. Consequently, the more it used, the more value companies tend to get from it. Unfortunately, companies do not get as much value as they could because bottlenecks limit the amount of simulation done. Tech-Clarity's research identifies those simulation bottlenecks, as well as best practices for overcoming them. This guest blog post describes the research process and shares some key findings. The complete report sharing findings and recommendations, can be accessed here (free of charge, registration required).

Read the post on the Siemens Femap Blog.

[post_title] => How Simulation Solves Some of Today’s Top Product Development Challenges - Guest Post on Siemens Blog

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => simulation-solves-todays-top-product-development-challenges-guest-siemens-blog

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:01

[post_modified_gmt] => 2022-11-15 03:26:01

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5605

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[13] => WP_Post Object

(

[ID] => 5593

[post_author] => 2572

[post_date] => 2016-08-18 11:43:33

[post_date_gmt] => 2016-08-18 15:43:33

[post_content] => Michelle Boucher shares new research on simulation in this Siemens guest post, Announcing New Research on FEA Simulation Bottlenecks. Simulation can be a powerful tool to help guide design decisions. Consequently, the more it used, the more value companies tend to get from it. Unfortunately, companies do not get as much value as they could because bottlenecks limit the amount of simulation done. Tech-Clarity's research identifies those simulation bottlenecks, as well as best practices for overcoming them. This guest blog post describes the research process and shares some key findings. The complete report sharing findings and recommendations, can be accessed here (free of charge, registration required).

Read the post on the Siemens Femap Blog.

[post_title] => 3 Ways Model-Based Systems Engineering (MBSE) Will Help You - Guest Post on PTC Blog

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => 3-ways-mbse-helps-ptc-guest-post

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:01

[post_modified_gmt] => 2022-11-15 03:26:01

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5584

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[15] => WP_Post Object

(

[ID] => 5569

[post_author] => 2

[post_date] => 2016-08-10 11:05:51

[post_date_gmt] => 2016-08-10 15:05:51

[post_content] =>

[post_title] => 3 Ways Model-Based Systems Engineering (MBSE) Will Help You - Guest Post on PTC Blog

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => 3-ways-mbse-helps-ptc-guest-post

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:01

[post_modified_gmt] => 2022-11-15 03:26:01

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5584

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[15] => WP_Post Object

(

[ID] => 5569

[post_author] => 2

[post_date] => 2016-08-10 11:05:51

[post_date_gmt] => 2016-08-10 15:05:51

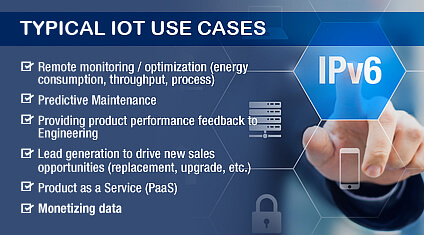

[post_content] =>  The Ten Build-Buy Factors for IoT Platforms ebook shares ten things companies should consider when deciding whether to build or buy the infrastructure required to support their Internet of Things (IoT) initiatives. The research shares practical experiences from several manufacturers ranging in size and IoT maturity. The eBook reports the complexities and lessons learned from their real experience supporting IoT and IIoT initiatives.

Click here for the full eBook, thank you to our sponsor Autodesk.

The Ten Build-Buy Factors for IoT Platforms ebook shares ten things companies should consider when deciding whether to build or buy the infrastructure required to support their Internet of Things (IoT) initiatives. The research shares practical experiences from several manufacturers ranging in size and IoT maturity. The eBook reports the complexities and lessons learned from their real experience supporting IoT and IIoT initiatives.

Click here for the full eBook, thank you to our sponsor Autodesk.

IoT Competence Transforming Competitive Landscape

The Internet of Things (IoT) is poised to disrupt the industrial status quo. We’re at an early inflection point with IoT similar to when businesses began adopting the web. At that time, people knew they needed to “get on the Internet” but weren’t exactly sure why or how it would impact their business. But they knew times were changing, and they did.

The competitive landscape was rewritten, innovative new businesses like Amazon loomed large, and traditional companies had to adapt or die. Welcome back to turbulent times.

IoT is coming into reach for more companies due to cheap sensors, embedded computers, wireless networks, and cloud server farms. Manufacturers are starting to see their competitors adopt IoT strategies and recognize the disruption could result in traditional industries polarizing into winners and losers. On the other hand, companies that master IoT have the opportunity to expand into new business arenas, much as Amazon started selling books with the intent of transforming the way consumers buy a wide variety of items.

The Internet of Things (IoT) is poised to disrupt the industrial status quo. We’re at an early inflection point with IoT similar to when businesses began adopting the web. At that time, people knew they needed to “get on the Internet” but weren’t exactly sure why or how it would impact their business. But they knew times were changing, and they did.

The competitive landscape was rewritten, innovative new businesses like Amazon loomed large, and traditional companies had to adapt or die. Welcome back to turbulent times.

IoT is coming into reach for more companies due to cheap sensors, embedded computers, wireless networks, and cloud server farms. Manufacturers are starting to see their competitors adopt IoT strategies and recognize the disruption could result in traditional industries polarizing into winners and losers. On the other hand, companies that master IoT have the opportunity to expand into new business arenas, much as Amazon started selling books with the intent of transforming the way consumers buy a wide variety of items.

Don't Go it Alone!

Don't Go it Alone!

Few companies, if any, should develop IoT infrastructure on their own. The transition to an IoT-enabled business is a valuable, but challenging journey. It’s important to recognize that it’s a business transformation and partner with the right advisors and technology providers. Most companies’ IoT initiatives will demand a wider selection of more advanced IT skills than they can afford. Even those with advanced skills will likely benefit by focusing internal efforts on use cases and changing relationship with customers and focus on core competencies and the big picture.

Finding a partner that can provide scalable, full-featured IoT infrastructure allows companies to focus their IoT investments. They should look for a partner that’s looking further into the future than they can afford to and working with other companies to learn. The partner should also have specialists in each of the critical IT disciplines. Finally, recognize that this will be a dynamic journey with starts, stops, and surprises. They should also look for assurances that the partner will be able to keep up and continue to invest in the future as the industry matures.

Finding a partner that can provide scalable, full-featured IoT infrastructure allows companies to focus their IoT investments. They should look for a partner that’s looking further into the future than they can afford to and working with other companies to learn. The partner should also have specialists in each of the critical IT disciplines. Finally, recognize that this will be a dynamic journey with starts, stops, and surprises. They should also look for assurances that the partner will be able to keep up and continue to invest in the future as the industry matures.

[post_title] => Ten Build-Buy Factors for IoT Platforms

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => iot-build

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:50

[post_modified_gmt] => 2022-11-15 03:27:50

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5569

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[16] => WP_Post Object

(

[ID] => 5548

[post_author] => 2

[post_date] => 2016-08-08 10:04:37

[post_date_gmt] => 2016-08-08 14:04:37

[post_content] =>

[post_title] => Ten Build-Buy Factors for IoT Platforms

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => iot-build

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:50

[post_modified_gmt] => 2022-11-15 03:27:50

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5569

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[16] => WP_Post Object

(

[ID] => 5548

[post_author] => 2

[post_date] => 2016-08-08 10:04:37

[post_date_gmt] => 2016-08-08 14:04:37

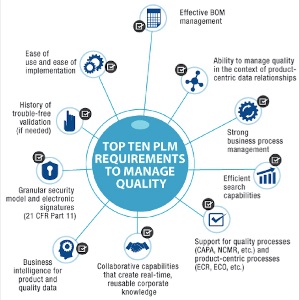

[post_content] =>  The Does Quality Belong in PLM? eBook explores the value of implementing quality management processes in a Product Lifecycle Management system. The research shares perspectives from several manufacturers about managing quality processes like CAPA and creating product documentation including Design History Files (DHF) and Design Master Records (DMR). The eBook looks at the value of using standalone Quality Management Systems (QMS) or implementing quality directly in PLM to ensure integration between quality, product data, and the product's digital thread. The report concludes with a list of Top Ten Requirements to Manage Quality in PLM, because not all PLM systems are fully capable of supporting quality and risk management processes.

Please enjoy the summary below. For the full report, please visit our sponsor Arena Solutions.

The Does Quality Belong in PLM? eBook explores the value of implementing quality management processes in a Product Lifecycle Management system. The research shares perspectives from several manufacturers about managing quality processes like CAPA and creating product documentation including Design History Files (DHF) and Design Master Records (DMR). The eBook looks at the value of using standalone Quality Management Systems (QMS) or implementing quality directly in PLM to ensure integration between quality, product data, and the product's digital thread. The report concludes with a list of Top Ten Requirements to Manage Quality in PLM, because not all PLM systems are fully capable of supporting quality and risk management processes.

Please enjoy the summary below. For the full report, please visit our sponsor Arena Solutions.

Quality Management and PLM

The Value of Quality and PLM Overlap

Quality Management and Product Lifecycle Management (PLM) are both proven disciplines that help companies improve quality and product profitability. These two initiatives are highly complementary, but are typically owned by different departments and traditionally managed as separate processes. This often leads to disparate Quality Management Systems (QMS) and PLM systems implemented with little integration supporting quality and product innovation. There is significant overlap between the information and processes managed by PLM and QMS. This begs the question whether they should be separate systems, integrated systems, or a single system.

For many companies, the cost of implementing and maintaining multiple software systems is prohibitive. Further, our experience suggests that a single, integrated solution suite is more valuable than a collection of disconnected capabilities.

Research Goals and Findings

Given the overlap and the importance of PLM to product innovation and product development, this eBook explores using PLM to manage quality processes and data. The research finds strong quality management capabilities in PLM related to:

There is significant overlap between the information and processes managed by PLM and QMS. This begs the question whether they should be separate systems, integrated systems, or a single system.

For many companies, the cost of implementing and maintaining multiple software systems is prohibitive. Further, our experience suggests that a single, integrated solution suite is more valuable than a collection of disconnected capabilities.

Research Goals and Findings

Given the overlap and the importance of PLM to product innovation and product development, this eBook explores using PLM to manage quality processes and data. The research finds strong quality management capabilities in PLM related to:

Product and Bill of Material (BOM) Centricity

Product and Bill of Material (BOM) Centricity- Business Process Focus

- Data Relationship Management

- Internal and Supply Chain Collaboration

Why Quality Management Belongs in PLM

Single and Consistent Source of Product Data

PLM and QMS are both valuable solutions, but together can result in significant data and process duplication. The most practical way for most companies to get a single, rationalized quality management and PLM solution is to leverage PLM to support quality along with product innovation, product development, and engineering processes. PLM is ideally suited to manage quality because it’s a collaborative system, spans the enterprise, and is built to connect the supply chain. Some leading PLM vendors have extended PLM to manage quality processes and put quality and product data into a unified, connected product record. This makes it easy to find information, develop insights using BI, and meet product documentation needs such as DMR and DHF.

Beyond data, PLM supports quality processes to integrate data, procedures, and people. These capabilities make PLM a natural fit for those that want to improve quality and reduce risk. Companies looking for quality management capabilities should consider PLM a strong option, particularly if they value a single solution.

PLM is ideally suited to manage quality because it’s a collaborative system, spans the enterprise, and is built to connect the supply chain. Some leading PLM vendors have extended PLM to manage quality processes and put quality and product data into a unified, connected product record. This makes it easy to find information, develop insights using BI, and meet product documentation needs such as DMR and DHF.

Beyond data, PLM supports quality processes to integrate data, procedures, and people. These capabilities make PLM a natural fit for those that want to improve quality and reduce risk. Companies looking for quality management capabilities should consider PLM a strong option, particularly if they value a single solution.

*This summary is an abbreviated version of the report and does not contain the full content. A link to download the full report is available above.

If you have difficulty obtaining a copy of the report, please contact us using the "Contact" link below.

[post_title] => Does Quality Management Belong in PLM? (eBook)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => quality-plm

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:11

[post_modified_gmt] => 2022-11-15 03:28:11

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5548

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 1

[filter] => raw

)

[17] => WP_Post Object

(

[ID] => 5535

[post_author] => 2

[post_date] => 2016-07-22 09:55:15

[post_date_gmt] => 2016-07-22 13:55:15

[post_content] => PTC caught some of my views on the Internet of Things on camera at a recent event. The videos include some of my thoughts along with those of PTC's Jill Newberg and fellow analysts Joe Barkai and Gartner's Tuong Nguyen.

The first one is on the IoT closing the loop in PLM, where I discuss how manufacturers no longer lose touch with their products - fundamentally changing the relationship between product, manufacturer, and customers.

https://youtu.be/RX6Klyo_1as

The second is about thoughts on the IoT market and its maturity and that companies should not just focus on technology but on how to use information and connectivity to improve profitability and revenue.

https://www.youtube.com/watch?v=c1AtOo5onW4

There's so much happening in this space and PTC's YouTube IoT playlist contains these and much more educational content, including the incorporation of Augmented Reality (AR) that they demonstrated at the event.

[post_title] => Tech-Clarity's Jim Brown Sharing IoT Thoughts at PTC Event

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => iot-vid

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:11

[post_modified_gmt] => 2022-11-15 03:26:11

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5535

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[18] => WP_Post Object

(

[ID] => 5439

[post_author] => 2572

[post_date] => 2016-07-21 11:45:44

[post_date_gmt] => 2016-07-21 15:45:44

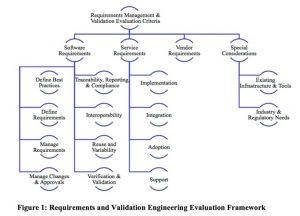

[post_content] => In this PTC guest post, Michelle Boucher discusses How to Select a Requirements and Validation Solution. There are many reasons projects fail, but a requirements and validation solution can help. However, selecting the right solution can be overwhelming. What should you use as buying criteria? What are your options if your requirements solution works well sometimes, but not always? This blog post introduces Tech-Clarity's Requirements and Validation Engineering Buyer's Guide: The Expert Guide to Requirements Validation. This requirements buyer's guide identifies key buying criteria and shares easy-to-follow checklists. You can then use these to help you select the right solution for your company.

Read the post on the PTC Integrity blog now.

*This summary is an abbreviated version of the report and does not contain the full content. A link to download the full report is available above.

If you have difficulty obtaining a copy of the report, please contact us using the "Contact" link below.

[post_title] => Does Quality Management Belong in PLM? (eBook)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => quality-plm

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:11

[post_modified_gmt] => 2022-11-15 03:28:11

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5548

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 1

[filter] => raw

)

[17] => WP_Post Object

(

[ID] => 5535

[post_author] => 2

[post_date] => 2016-07-22 09:55:15

[post_date_gmt] => 2016-07-22 13:55:15

[post_content] => PTC caught some of my views on the Internet of Things on camera at a recent event. The videos include some of my thoughts along with those of PTC's Jill Newberg and fellow analysts Joe Barkai and Gartner's Tuong Nguyen.

The first one is on the IoT closing the loop in PLM, where I discuss how manufacturers no longer lose touch with their products - fundamentally changing the relationship between product, manufacturer, and customers.

https://youtu.be/RX6Klyo_1as

The second is about thoughts on the IoT market and its maturity and that companies should not just focus on technology but on how to use information and connectivity to improve profitability and revenue.

https://www.youtube.com/watch?v=c1AtOo5onW4

There's so much happening in this space and PTC's YouTube IoT playlist contains these and much more educational content, including the incorporation of Augmented Reality (AR) that they demonstrated at the event.

[post_title] => Tech-Clarity's Jim Brown Sharing IoT Thoughts at PTC Event

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => iot-vid

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:11

[post_modified_gmt] => 2022-11-15 03:26:11

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5535

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[18] => WP_Post Object

(

[ID] => 5439

[post_author] => 2572

[post_date] => 2016-07-21 11:45:44

[post_date_gmt] => 2016-07-21 15:45:44

[post_content] => In this PTC guest post, Michelle Boucher discusses How to Select a Requirements and Validation Solution. There are many reasons projects fail, but a requirements and validation solution can help. However, selecting the right solution can be overwhelming. What should you use as buying criteria? What are your options if your requirements solution works well sometimes, but not always? This blog post introduces Tech-Clarity's Requirements and Validation Engineering Buyer's Guide: The Expert Guide to Requirements Validation. This requirements buyer's guide identifies key buying criteria and shares easy-to-follow checklists. You can then use these to help you select the right solution for your company.

Read the post on the PTC Integrity blog now.

[post_title] => How to Select a Requirements and Validation Solution - Guest Post on PTC Blog

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => requirements_buyers_guide

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:00

[post_modified_gmt] => 2022-11-15 03:26:00

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5439

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[19] => WP_Post Object

(

[ID] => 5525

[post_author] => 2

[post_date] => 2016-07-20 15:47:03

[post_date_gmt] => 2016-07-20 19:47:03

[post_content] =>

[post_title] => How to Select a Requirements and Validation Solution - Guest Post on PTC Blog

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => requirements_buyers_guide

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:00

[post_modified_gmt] => 2022-11-15 03:26:00

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5439

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[19] => WP_Post Object

(

[ID] => 5525

[post_author] => 2

[post_date] => 2016-07-20 15:47:03

[post_date_gmt] => 2016-07-20 19:47:03

[post_content] =>  Finding PLM to Fit Midsized CPG Companies explains how smaller Consumer Packaged Goods (CPG) companies find themselves stuck between full-featured Product Lifecycle Management (PLM) systems that feel out of reach and less capable solutions including cloud-based file sharing or very basic data management applications. They know they can’t afford the errors and inefficiency inherent to informal data and process management, but can’t afford a large time, resource, and financial investment to fix their problems. Unfortunately simple solutions, while very attractive, fall short of their real needs, don’t help them improve their business the way they want to, and don’t leave them room to grow in the future. They need to find the “sweet spot” of a solution that helps them get started quickly with the basics of controlling, managing, and sharing product data but provides the features they need to be successful now and into the future.

Please enjoy the summary below.

For the full eBook, please visit our sponsor Dassault Systèmes and scroll down to the E-Books and Infographics section (free of charge, registration required).

Finding PLM to Fit Midsized CPG Companies explains how smaller Consumer Packaged Goods (CPG) companies find themselves stuck between full-featured Product Lifecycle Management (PLM) systems that feel out of reach and less capable solutions including cloud-based file sharing or very basic data management applications. They know they can’t afford the errors and inefficiency inherent to informal data and process management, but can’t afford a large time, resource, and financial investment to fix their problems. Unfortunately simple solutions, while very attractive, fall short of their real needs, don’t help them improve their business the way they want to, and don’t leave them room to grow in the future. They need to find the “sweet spot” of a solution that helps them get started quickly with the basics of controlling, managing, and sharing product data but provides the features they need to be successful now and into the future.

Please enjoy the summary below.

For the full eBook, please visit our sponsor Dassault Systèmes and scroll down to the E-Books and Infographics section (free of charge, registration required).

Midsize Manufacturers Stuck in Between

Midsize consumer packaged goods (CPG) companies, their suppliers, and their partners face continuous pressure in today’s competitive, global marketplace. They have to adopt strategies combining product innovation and agility to survive. But developing and launching successful products today is complex. It requires deep customer insights, technical knowhow, and collaboration. Midsize companies have to overcome this complexity to compete with larger competitors. They have to connect closely with consumers and introduce new products quickly and efficiently to meet their needs. Product Lifecycle Management (PLM) software can help. It drives better product development performance by managing product-related data, processes, and projects. While smaller companies may be able to control, access, and share product data with relatively simple content sharing tools, larger companies rely on full-featured PLM to help automate processes and share data across global supply chains. Midsize companies may find themselves in-between because:- Product and organizational complexity drive them beyond basic PDM capabilities

- A full-featured PLM implementation may feel out of reach

Get Started with the Right PLM Solution

Core PLM can quickly add value to midsized companies by helping them combat complexity, improve productivity, and stay closer to customers. Recognize the potential value of a fully featured PLM with all of the bells and whistles, but be honest with yourself about whether your company can afford the time and effort to get there (at least right away). Don’t take on too much. Start with the basics and get value quickly, but recognize the shortcomings of simple file sharing solutions that fall short for the complex products and product development environments common to midsize manufacturers. Look for a solution that allows you to design in the context of your products in real time, but also in the context of processes and product development projects. In addition, look for PLM that incorporates automation including integrated design tools and automated project updates to keep product developers focused on innovation instead of managing files.

Finally, make sure to leave your company room to grow as your business dictates, using the initial implementation as a foundation for greater improvements. Find a solution that offers more advanced capabilities, such as simulation, that your company can leverage when they are ready.

*This summary is an abbreviated version of the report and does not contain the full content. A link to download the full report is available above. If you have difficulty obtaining a copy of the report, please contact us using the "Contact" link below.

[post_title] => Finding PLM to Fit Midsized CPG Companies (eBook)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cpg-mid-plm

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:11

[post_modified_gmt] => 2022-11-15 03:28:11

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5525

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

)

[post_count] => 20

[current_post] => -1

[before_loop] => 1

[in_the_loop] =>

[post] => WP_Post Object

(

[ID] => 5737

[post_author] => 2

[post_date] => 2016-09-28 10:12:54

[post_date_gmt] => 2016-09-28 14:12:54

[post_content] => Jim Brown contributed a post to the Autodesk Fusion Connect site sharing the Top Five Factors for a Successful Industrial IoT Implementation. The post provides an introduction to our Ten Build-Buy Factors for IoT Platforms eBook tailored to Engineers so they can understand not only how to support their company's IoT initiative, but also how to gain direct benefits for Engineering. Please enjoy the excerpt below and the read the rest on the Autodesk site.

Don’t take on too much. Start with the basics and get value quickly, but recognize the shortcomings of simple file sharing solutions that fall short for the complex products and product development environments common to midsize manufacturers. Look for a solution that allows you to design in the context of your products in real time, but also in the context of processes and product development projects. In addition, look for PLM that incorporates automation including integrated design tools and automated project updates to keep product developers focused on innovation instead of managing files.

Finally, make sure to leave your company room to grow as your business dictates, using the initial implementation as a foundation for greater improvements. Find a solution that offers more advanced capabilities, such as simulation, that your company can leverage when they are ready.

*This summary is an abbreviated version of the report and does not contain the full content. A link to download the full report is available above. If you have difficulty obtaining a copy of the report, please contact us using the "Contact" link below.

[post_title] => Finding PLM to Fit Midsized CPG Companies (eBook)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cpg-mid-plm

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:11

[post_modified_gmt] => 2022-11-15 03:28:11

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5525

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

)

[post_count] => 20

[current_post] => -1

[before_loop] => 1

[in_the_loop] =>

[post] => WP_Post Object

(

[ID] => 5737

[post_author] => 2

[post_date] => 2016-09-28 10:12:54

[post_date_gmt] => 2016-09-28 14:12:54

[post_content] => Jim Brown contributed a post to the Autodesk Fusion Connect site sharing the Top Five Factors for a Successful Industrial IoT Implementation. The post provides an introduction to our Ten Build-Buy Factors for IoT Platforms eBook tailored to Engineers so they can understand not only how to support their company's IoT initiative, but also how to gain direct benefits for Engineering. Please enjoy the excerpt below and the read the rest on the Autodesk site.

Welcome to the IIoT

Welcome to the IIoT

Supporting the Industrial Internet is now an important part of the Engineering domain. For some, it’s because their customers are operating their products in the Industrial Internet of Things (IIoT). For others, it’s because their company is using the IIoT to monitor and control equipment and devices in their own facilities. For many, both are happening at the same time. The IIoT movement changes the game for companies, their customers, and their Engineering department.

The potential value of the IIoT is immense, and companies are responding. Potential benefits range from productivity and cost savings to fundamentally resetting the value proposition and relationship between companies and their business partners, including suppliers, service partners, and customers. Whether a company is pursuing an IoT or IIoT initiative to support customers, improve their own business, or make sure to keep up with the competition, it will have an impact on Engineering.

Adapting Engineering to the IIoT

What do engineers need to do in order to survive and thrive in this brave new world? One thing that’s clear is that the IIoT drives new product design requirements. Beyond products, it also drives significant infrastructure requirements, as discussed in Ten Build-Buy Factors for IoT Platforms. Engineers play a key role in unlocking the IoT and the IIoT value in both areas. This introduction shares some of the ways engineers need to think differently to support company-wide IIoT initiatives. But Engineering can also gain their own value from these initiatives. This introduction highlights the potential benefits Engineering can receive directly from participating in the IIoT, and highlights specific areas in the ten build-buy factors that are the most important for engineers to consider. Let’s get started.Engineer’s Role Supporting the IIoT – Design

Engineers can play multiple roles supporting IIoT initiatives....... *This summary is an abbreviated version of the post. Please see the full Top Five Factors for a Successful Industrial IoT Implementation post on the Autodesk website (free of charge, no registration required). If you have difficulty obtaining a copy of the report, please contact the author at jim.brown@tech-clarity.com or by clicking our Contact button. [post_title] => Top Five Factors for a Successful IIoT Implementation (guest post) [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => iiot-intro [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:25:32 [post_modified_gmt] => 2022-11-15 03:25:32 [post_content_filtered] => [post_parent] => 0 [guid] => http://tech-clarity.com/?p=5737 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [comment_count] => 0 [current_comment] => -1 [found_posts] => 876 [max_num_pages] => 44 [max_num_comment_pages] => 0 [is_single] => [is_preview] => [is_page] => [is_archive] => [is_date] => [is_year] => [is_month] => [is_day] => [is_time] => [is_author] => [is_category] => [is_tag] => [is_tax] => [is_search] => [is_feed] => [is_comment_feed] => [is_trackback] => [is_home] => 1 [is_privacy_policy] => [is_404] => [is_embed] => [is_paged] => [is_admin] => [is_attachment] => [is_singular] => [is_robots] => [is_favicon] => [is_posts_page] => [is_post_type_archive] => [query_vars_hash:WP_Query:private] => d4955089b29e7e70c8bc3a4738cdddd6 [query_vars_changed:WP_Query:private] => 1 [thumbnails_cached] => [allow_query_attachment_by_filename:protected] => [stopwords:WP_Query:private] => [compat_fields:WP_Query:private] => Array ( [0] => query_vars_hash [1] => query_vars_changed ) [compat_methods:WP_Query:private] => Array ( [0] => init_query_flags [1] => parse_tax_query ) [query_cache_key:WP_Query:private] => wp_query:a8a162f4df0937383f855f7b056cd7a7:0.08514500 17692672530.09458100 1769267253 )All Results for "All"

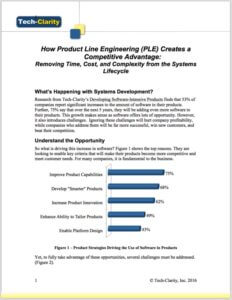

How Product Line Engineering (PLE) Creates a Competitive Advantage

How Product Line Engineering (PLE) Creates a Competitive Advantage: Removing Time, Cost, and Complexity from the Systems Lifecycle discusses the growing importance of embedded software in today’s products and the resulting complexity. The report highlights the negative impacts of not managing this complexity. Despite these impacts, there are benefits of using the right software. Those using the right…

Getting Started with PDM (animation)

This short Tech-Clarity TV animation explains how manufacturers can get started with Product Data Management. The video offers findings from The Business Value of Product Data Management that finds that manufacturers can get off to a fast start with preconfigured solutions but still leave themselves room to grow on a foundation that provides more advanced capabilities. This episode is sponsored by Siemens PLM. Learn…

Tech-Clarity TV – Practical Advice on Creating the IoT Platform (video)

This episode of Tech-Clarity TV reviews the inherent complexity involved in supporting IoT initiatives and reviews key considerations for a successful IoT program. The video blog shares real-world perspectives from several manufacturers on building versus buying IoT and IIoT infrastructure. For more information, please see a summary of the related Ten Build Buy Factors for IoT Platforms…

Addressing Bottlenecks in Simulation (webcast)

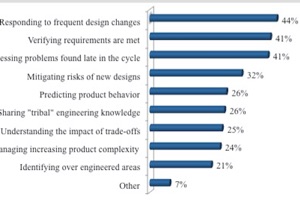

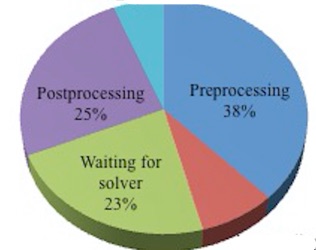

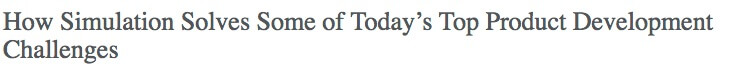

Hear Michelle Boucher share her recent research on Simulation Bottlenecks during a this webinar. Digital Engineering’s Kenneth Wong will moderate this webinar sponsored by Siemens Femap. This webinar will reveal: The top improvement areas you should focus on to get even more value from simulation Best practices followed by Top Performing companies to overcome simulation bottlenecks Selection criteria to help…

Top Five Five Factors for a Successful IIoT Implementation (webcast replay)

Jim Brown presented his recent research on building versus buying IIoT infrastructure in the upcoming Top 5 Factors for a Successful Industrial IoT Implementation webcast on Engineering.com (sponsored by Autodesk). The webcast also featured Autodesk’s Head of IoT, Bryan Kester, sharing how IIoT can help improve product service, close the loop on engineering designs, and…

How A&D Companies Get More Value from Simulation – Guest Post on Siemens Blog

How Aerospace and Defense (A&D) Companies Get More Value from Simulation is a new Siemens guest post. In this post, Michelle Boucher explores how A&D companies use simulation. The post highlights challenges faced by A&D companies and then shares survey results revealing some of the top ways A&D solve them. Read the post on the…

Avoid Product Launch Failure by Aligning Quality and Engineering (webcast replay)

Tech-Clarity’s Jim Brown joined Arena Solutions’ Ann McGuire on a TechBriefs webcast about avoiding product launch failures. Jim and Ann discussed why products fail and what companies are doing to improve product development success across the product lifecycle. The webcast, Avoid Product Launch Failure: Best Practices for Aligning Your Engineering and Quality Teams, is sponsored by Arena…

Integrating Dassault Systemes’ 3DEXPERIENCE Platform with SAP ERP (guest post)

Jim Brown contributed his views on integrating Product Innovation Platforms / PLM to ERP in a recent guest post for Cideon Software. The post pays specific attention to how to integrate the 3DEXPERIENCE platform with SAP. The post shares the increasing importance of integration, the need for a repeatable approach, and some key considerations about finding a partner…

What Is an Optimized Product Design? – Guest Post on Siemens Blog

In a new Siemens guest post, What Is an Optimized Product Design? Michelle Boucher discusses how companies use simulation to optimize their products. However, the term optimization came be a bit vague as it means different things to different people. To clarify the term, this post shares additional data from our recent study, Addressing the Bottlenecks of FEA…

How Should You Use Simulation? – Guest Post on Siemens Blog

Michelle Boucher shares additional findings from our recent study, Addressing the Bottlenecks of FEA Simulation in this Siemens guest post, How Should You Use Simulation. This guest post discusses some of the the top ways Top Performing companies apply simulation during product development. The post shares additional survey data on the benefits Top Performers report as a result of using simulation….

Composite State of the Market (Survey Findings)

Tech-Clarity’s research report, Composites State of the Market: Using Composites as a Competitive Advantage, examines survey findings on material trends and composites. Over 240 companies participated in the survey. The research finds that new materials are a significant source of product complexity. The research also finds that of new materials, composites in particular, will see a…

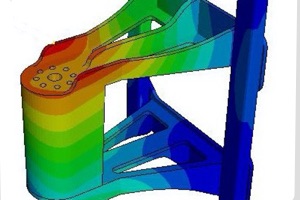

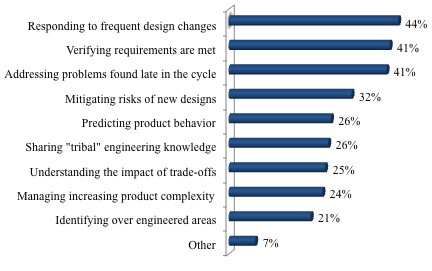

How Simulation Solves Some of Today’s Top Product Development Challenges – Guest Post on Siemens Blog

In this Siemens guest post, How Simulation Solves Some of Today’s Top Product Development Challenges Michelle Boucher shares additional findings from our recent study, Addressing the Bottlenecks of FEA Simulation. This guest post shares some of the top development challenges companies struggle with and then shares some of the ways Top Performing companies address these challenges. Simulation is…

Announcing New Research on FEA Simulation Bottlenecks – Guest Post on Siemens Blog

Michelle Boucher shares new research on simulation in this Siemens guest post, Announcing New Research on FEA Simulation Bottlenecks. Simulation can be a powerful tool to help guide design decisions. Consequently, the more it used, the more value companies tend to get from it. Unfortunately, companies do not get as much value as they could because bottlenecks…

3 Ways Model-Based Systems Engineering (MBSE) Will Help You – Guest Post on PTC Blog

Michelle Boucher describes 3 ways model-based systems engineering (MBSE) can help product development teams in this PTC guest post. While developing today’s complex systems can be extremely challenging, model-based systems engineering (MBSE) can make it easier. MBSE uses a system model as a visual reference to support the development process. This guest post explains how a system model improves…

Ten Build-Buy Factors for IoT Platforms

The Ten Build-Buy Factors for IoT Platforms ebook shares ten things companies should consider when deciding whether to build or buy the infrastructure required to support their Internet of Things (IoT) initiatives. The research shares practical experiences from several manufacturers ranging in size and IoT maturity. The eBook reports the complexities and lessons learned from their real…

Does Quality Management Belong in PLM? (eBook)

The Does Quality Belong in PLM? eBook explores the value of implementing quality management processes in a Product Lifecycle Management system. The research shares perspectives from several manufacturers about managing quality processes like CAPA and creating product documentation including Design History Files (DHF) and Design Master Records (DMR). The eBook looks at the value of using standalone Quality…

Tech-Clarity’s Jim Brown Sharing IoT Thoughts at PTC Event

PTC caught some of my views on the Internet of Things on camera at a recent event. The videos include some of my thoughts along with those of PTC’s Jill Newberg and fellow analysts Joe Barkai and Gartner’s Tuong Nguyen. The first one is on the IoT closing the loop in PLM, where I discuss…

How to Select a Requirements and Validation Solution – Guest Post on PTC Blog

In this PTC guest post, Michelle Boucher discusses How to Select a Requirements and Validation Solution. There are many reasons projects fail, but a requirements and validation solution can help. However, selecting the right solution can be overwhelming. What should you use as buying criteria? What are your options if your requirements solution works well sometimes, but not always?…

Finding PLM to Fit Midsized CPG Companies (eBook)

Finding PLM to Fit Midsized CPG Companies explains how smaller Consumer Packaged Goods (CPG) companies find themselves stuck between full-featured Product Lifecycle Management (PLM) systems that feel out of reach and less capable solutions including cloud-based file sharing or very basic data management applications. They know they can’t afford the errors and inefficiency inherent to informal data and…

Hear Michelle Boucher share her recent research on

Hear Michelle Boucher share her recent research on