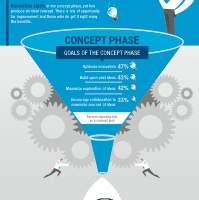

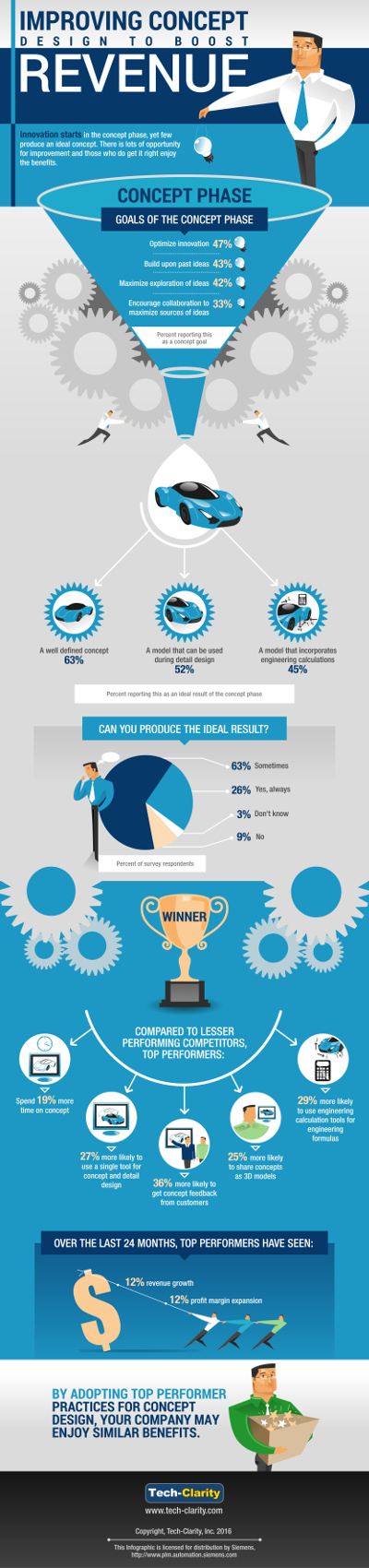

The concept phase is critical for innovation. Tech-Clarity’s Improving Concept Design to Boost Revenue infographic steps through what companies attempt to achieve during the concept phase, how the most successful companies approach concept development, and the benefits they enjoy as a result. Additional information can be found in our related research report, Improving Concept Design: Innovating at the Front End to Drive…

- Executive Overview

- Why Should IEMs Care about Innovation?

- Clarify the Meaning of Innovation

- Identify Challenges that Hurt Innovation Success

- Establish a Culture of Innovation

- Invest in the Concept Phase

- Define Processes

- Take Advantage of Available Technologies

- Conclusion

- Recommendations

- About the Author

Executive Overview

The video series is brought to you by Autodesk PLM360.

PLM411 brings you straight talk about how manufacturers can accelerate product innovation and product development with PLM.

For more visit PLM411.com or the Tech-Clarity YouTube Channel.

https://youtu.be/H2XrFPvWRFo

The video series is brought to you by Autodesk PLM360.

PLM411 brings you straight talk about how manufacturers can accelerate product innovation and product development with PLM.

For more visit PLM411.com or the Tech-Clarity YouTube Channel.

https://youtu.be/H2XrFPvWRFo

Prior Episode: The previous video shares some of the funnier moments from our 2015 infomercials and then tackles a serious question, “Should startups use PLM?,” in an interview with Autodesk’s Laurent Rains and Tech-Clarity’s Jim Brown.

[post_title] => PLM411 PLM Flexibility and Supporting Corporate Strategy Interview with Suretank

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => plm411-13

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:29:57

[post_modified_gmt] => 2022-11-15 03:29:57

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5101

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[4] => WP_Post Object

(

[ID] => 5034

[post_author] => 2572

[post_date] => 2016-02-17 11:23:39

[post_date_gmt] => 2016-02-17 16:23:39

[post_content] =>

Prior Episode: The previous video shares some of the funnier moments from our 2015 infomercials and then tackles a serious question, “Should startups use PLM?,” in an interview with Autodesk’s Laurent Rains and Tech-Clarity’s Jim Brown.

[post_title] => PLM411 PLM Flexibility and Supporting Corporate Strategy Interview with Suretank

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => plm411-13

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:29:57

[post_modified_gmt] => 2022-11-15 03:29:57

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5101

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[4] => WP_Post Object

(

[ID] => 5034

[post_author] => 2572

[post_date] => 2016-02-17 11:23:39

[post_date_gmt] => 2016-02-17 16:23:39

[post_content] =>  Improving Concept Design: Innovating at the Front End to Drive Revenue Opportunities examines the importance of the concept phase. The report reveals survey results highlighting not only what companies can do to improve the concept phase, but also how to take advantage of concept work during later stages of product development.

Please enjoy the summary below, or click the report or title to download the full PDF (free of charge, no registration required).

Additional information can be found in our companion infographic.

For for more information on concept design, please visit our sponsor, Siemens.

Improving Concept Design: Innovating at the Front End to Drive Revenue Opportunities examines the importance of the concept phase. The report reveals survey results highlighting not only what companies can do to improve the concept phase, but also how to take advantage of concept work during later stages of product development.

Please enjoy the summary below, or click the report or title to download the full PDF (free of charge, no registration required).

Additional information can be found in our companion infographic.

For for more information on concept design, please visit our sponsor, Siemens.

Table of Contents

- Executive Overview

- Understand the Importance of the Concept Phase

- Identifying the Top Performers

- Optimize the Conceptual Phase Recognize the Challenges of Concept Development

- Manage the Concept Phase

- Facilitate Collaboration

- Enable Reuse Capture

- Engineering Knowledge

- Conclusion

- Recommendations

- About the Author

- About the Research

Executive Overview

- Only 52% of the concept is reused during detail design

- Companies agree more should be reused

- Companies believe they would save 45% of overall development time by optimizing concept design reuse

Improving Profitability for Configured Products: Leveraging Sales Configuration and Design Automation explores how companies can profitability tailor products to meet customer needs. The research investigates the experiences of several companies, revealing several key areas companies should focus on to improve their profitability.

Please enjoy the summary below, or click the report to download a PDF overview (free of charge, no registration required).

For the full report, please visit our sponsor, DriveWorks, (free of charge, no registration required).

Improving Profitability for Configured Products: Leveraging Sales Configuration and Design Automation explores how companies can profitability tailor products to meet customer needs. The research investigates the experiences of several companies, revealing several key areas companies should focus on to improve their profitability.

Please enjoy the summary below, or click the report to download a PDF overview (free of charge, no registration required).

For the full report, please visit our sponsor, DriveWorks, (free of charge, no registration required).

Table of Contents

- Executive Overview

- Optimize Profitability

- Support Guided Selling

- Automate Manufacturability Checks

- Streamline Sales to Manufacturing

- Create More Revenue Opportunities

- Enable ETO Best Practices

- Ensure Quote Accuracy

- Integrate to the Enterprise

- Enable Web and Mobile Platforms

- Keep the Implementation Simple

- Conclusion

- Recommendations

- About the Author

Executive Overview

Manufacturers have a tough job competing in today’s global environment. Global competition, price sensitivity, time to market pressures, and increasing complexity all make it very difficult for manufacturers to be successful. Competitively differentiating your business and its products is hard while facing all these pressures. In addition, customers expect more. To capitalize on this trend, a company can set itself and its products apart by tailoring products to customer needs with a Design to Order (DTO), Configure to Order (CTO), or Engineer to Order (ETO) strategy. Among the many benefits, customization and personalization:- Offer customers exactly what they want

- Create competitive differentiation

- Enable a price premium

- Higher productivity

- More accurate quotes

- Fewer errors

- Optimized manufacturing processes

- Less waste

Jim Brown offers some advice on selecting PLM systems in this TechTarget article A PLM Systems Comparison of the Industry's Top Tools. The report also shares some insights on the leading PLM vendors.

This is the final article of a four part series. Prior article What can PLM technology dor for Enterprises? explores the benefits of PLM and PLM tools can cure and prevent product development ailments describes who can benefit from Product Lifecycle Management. The previous article, Choosing a PLM System? Start with Strategy! provides practical advice on choosing a PLM tool.

Jim Brown offers some advice on selecting PLM systems in this TechTarget article A PLM Systems Comparison of the Industry's Top Tools. The report also shares some insights on the leading PLM vendors.

This is the final article of a four part series. Prior article What can PLM technology dor for Enterprises? explores the benefits of PLM and PLM tools can cure and prevent product development ailments describes who can benefit from Product Lifecycle Management. The previous article, Choosing a PLM System? Start with Strategy! provides practical advice on choosing a PLM tool.

[post_title] => Selecting the Right PLM Partner

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => tech-target-4

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:53

[post_modified_gmt] => 2022-11-15 03:25:53

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5040

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[7] => WP_Post Object

(

[ID] => 5022

[post_author] => 2

[post_date] => 2016-01-21 09:34:33

[post_date_gmt] => 2016-01-21 14:34:33

[post_content] => This video shares some of the funnier moments from our 2015 infomercials and then tackles a serious question, "Should startups use PLM?," in an interview with Autodesk's Laurent Rains and Tech-Clarity's Jim Brown.

[post_title] => Selecting the Right PLM Partner

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => tech-target-4

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:53

[post_modified_gmt] => 2022-11-15 03:25:53

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5040

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[7] => WP_Post Object

(

[ID] => 5022

[post_author] => 2

[post_date] => 2016-01-21 09:34:33

[post_date_gmt] => 2016-01-21 14:34:33

[post_content] => This video shares some of the funnier moments from our 2015 infomercials and then tackles a serious question, "Should startups use PLM?," in an interview with Autodesk's Laurent Rains and Tech-Clarity's Jim Brown.

The video series is brought to you by Autodesk PLM360.

PLM411 brings you straight talk about how manufacturers can accelerate product innovation and product development with PLM.

For more visit PLM411.com or the Tech-Clarity YouTube Channel.

https://youtu.be/V-8PO1t_zeI

The video series is brought to you by Autodesk PLM360.

PLM411 brings you straight talk about how manufacturers can accelerate product innovation and product development with PLM.

For more visit PLM411.com or the Tech-Clarity YouTube Channel.

https://youtu.be/V-8PO1t_zeI

Prior Episode: How do you tell true cloud PLM software versus other SaaS options and why is it important? We start this episode by poking some fun at old software disguised as cloud. Then, Jim Brown interviews Excellims Corporation's VP of Engineering Mark Osgood who shares his experience outgrowing spreadsheets for managing product lifecycles, finding PLM systems cost prohibitive, and then implementing a "cloud" PLM solution that wasn't truly cloud, with poor results. Then hes implemented a native cloud PLM solution. The differences in performance is dramatic.

Prior Episode: How do you tell true cloud PLM software versus other SaaS options and why is it important? We start this episode by poking some fun at old software disguised as cloud. Then, Jim Brown interviews Excellims Corporation's VP of Engineering Mark Osgood who shares his experience outgrowing spreadsheets for managing product lifecycles, finding PLM systems cost prohibitive, and then implementing a "cloud" PLM solution that wasn't truly cloud, with poor results. Then hes implemented a native cloud PLM solution. The differences in performance is dramatic.

Next Episode: In this episode of PLM411, Tech-Clarity's Jim Brown discusses the PLM evolution at Suretank with Barry Woods, Systems Project Manager. Barry shares that Suretank had very traditional goals for PLM, primarily revision management and getting data under control. That was a success, but new management arrived and shifted company focus to World Class Customer Care. Suretank leveraged the flexibility of their PLM system to implement new capabilities aligned with the revised corporate strategy and ended up with huge business benefits. Barry shares they have continued plans to improve performance with PLM.

[post_title] => PLM411 Infomercial Recap / Interview on Whether Startups Should use PLM

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => plm411-12

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:29:56

[post_modified_gmt] => 2022-11-15 03:29:56

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5022

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[8] => WP_Post Object

(

[ID] => 4969

[post_author] => 2

[post_date] => 2016-01-20 12:08:14

[post_date_gmt] => 2016-01-20 17:08:14

[post_content] => Jim Brown joins Mark Rogers of Price HVAC and Rick Smith of Siemens PLM to discuss how to improve ETO processes and performance. Jim will share findings from a recent survey on what strategies, best practices, and enabling technologies top performing manufacturers use to gain higher profits from their customized products.

Register now (free of charge, registration required)

Next Episode: In this episode of PLM411, Tech-Clarity's Jim Brown discusses the PLM evolution at Suretank with Barry Woods, Systems Project Manager. Barry shares that Suretank had very traditional goals for PLM, primarily revision management and getting data under control. That was a success, but new management arrived and shifted company focus to World Class Customer Care. Suretank leveraged the flexibility of their PLM system to implement new capabilities aligned with the revised corporate strategy and ended up with huge business benefits. Barry shares they have continued plans to improve performance with PLM.

[post_title] => PLM411 Infomercial Recap / Interview on Whether Startups Should use PLM

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => plm411-12

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:29:56

[post_modified_gmt] => 2022-11-15 03:29:56

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5022

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[8] => WP_Post Object

(

[ID] => 4969

[post_author] => 2

[post_date] => 2016-01-20 12:08:14

[post_date_gmt] => 2016-01-20 17:08:14

[post_content] => Jim Brown joins Mark Rogers of Price HVAC and Rick Smith of Siemens PLM to discuss how to improve ETO processes and performance. Jim will share findings from a recent survey on what strategies, best practices, and enabling technologies top performing manufacturers use to gain higher profits from their customized products.

Register now (free of charge, registration required)

[post_title] => Webcast Driving a Competitive Edge Through Customization

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => etowebcast

[to_ping] =>

[pinged] =>

[post_modified] => 2025-01-31 11:39:19

[post_modified_gmt] => 2025-01-31 16:39:19

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4969

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[9] => WP_Post Object

(

[ID] => 4975

[post_author] => 2572

[post_date] => 2016-01-18 15:25:57

[post_date_gmt] => 2016-01-18 20:25:57

[post_content] =>

[post_title] => Webcast Driving a Competitive Edge Through Customization

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => etowebcast

[to_ping] =>

[pinged] =>

[post_modified] => 2025-01-31 11:39:19

[post_modified_gmt] => 2025-01-31 16:39:19

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4969

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[9] => WP_Post Object

(

[ID] => 4975

[post_author] => 2572

[post_date] => 2016-01-18 15:25:57

[post_date_gmt] => 2016-01-18 20:25:57

[post_content] =>

Are You Changing CAD Tools? What You Should Know shares survey results exploring the motivating factors behind changing CAD tools as well what companies can expect when making a change. The research examines the experiences of companies who have gone through a CAD change. It reveals key metrics such as the how much legacy data companies convert, how long to resume full productivity, and how much training is involved. The research also identifies what Top Performing companies look for in both a CAD tool and the vendor who provides that tool.

Please enjoy the summary below, or click the report to download a PDF overview (free of charge, no registration required).

For the full report, please visit our sponsor, Dassault Systèmes SOLIDWORKS, (free of charge, registration required).

Are You Changing CAD Tools? What You Should Know shares survey results exploring the motivating factors behind changing CAD tools as well what companies can expect when making a change. The research examines the experiences of companies who have gone through a CAD change. It reveals key metrics such as the how much legacy data companies convert, how long to resume full productivity, and how much training is involved. The research also identifies what Top Performing companies look for in both a CAD tool and the vendor who provides that tool.

Please enjoy the summary below, or click the report to download a PDF overview (free of charge, no registration required).

For the full report, please visit our sponsor, Dassault Systèmes SOLIDWORKS, (free of charge, registration required).

Table of Contents

- Executive Overview

- Understand Business Needs for Design

- What Drives a Change in CAD?

- Set Expectations for the Change

- Identifying Top Performers

- Identify the Right CAD Solution

- Extend CAD

- Conclusion

- Recommendations

- About the Author

- About the Research

Executive Overview

If you are competing in today’s global economy, it is not easy. Significant global competition plus pressure from new entrants and innovative start-ups make it difficult to stand out. To improve competitiveness, Tech-Clarity’s study, Product Lifecycle Management Beyond Managing CAD, finds companies have shifted focus from market factors like time-to-market or cost to product-centric strategies. Design tools, especially CAD, are key to executing these product strategies. With the right design tools, companies are better positioned to quickly bring high-performing, high-quality, innovative products to market. Companies looking to upgrade these tools to keep up with competitors may want to consider switching CAD tools. So what should you do if you find your CAD tool is holding you back? What if your company needs to update CAD tools? Why would you consider a change? What should you expect? Is it worth the time to convert archived data into a new format? Most importantly, do the benefits outweigh potential risks? Tech-Clarity surveyed 192 companies to answer these questions. While there are many interesting findings, the most striking is that business reasons rather than problems with CAD tools have become more influential when choosing a CAD tool and are motivating factors behind the need to switch tools. Growing influencers include supply chains, relationships, the vendor’s vision for design, and the CAD vendors’ full breadth of offerings. This big picture view of CAD indicates higher levels of management make buying decisions and they view CAD as a strategic piece of a larger product development solution. The biggest challenges of switching CAD tools are overcoming the learning curve and reusing legacy data. However, not all legacy data needs to be converted and in fact, companies only convert about half of it, 52%. Despite the efforts involved, companies who have made a CAD change tend to be very happy. Eighty-three percent (83%) rate their satisfaction a 4 or 5 on a scale of 1 to 5. The study also identified what successful companies look for. When selecting a new CAD tool, Top Performers are more likely to consider ease of use, Technical Support, software quality, and market share, which includes the size of the user community. Since implementing their current CAD tools, Top Performers have reduced development time by 19%, development costs by15%, and the time to implement ECOs (engineering change orders) by 16%, putting them at a significant competitive advantage. They have also been able to increase the number of design iterations by 17%, which leads to greater innovation. [post_title] => Are You Changing CAD Tools? [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => changing-cad [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:27:47 [post_modified_gmt] => 2022-11-15 03:27:47 [post_content_filtered] => [post_parent] => 0 [guid] => http://tech-clarity.com/?p=4975 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 1 [filter] => raw ) [10] => WP_Post Object ( [ID] => 4961 [post_author] => 2 [post_date] => 2016-01-11 15:17:25 [post_date_gmt] => 2016-01-11 20:17:25 [post_content] => The The CPG Digital Thread ebook shares how consumer packaged goods (CPG) companies can streamline their product innovation and commercialization practices by innovating along the digital thread. It shares how companies can simultaneously enable R&D to innovate more efficiently while capturing the resulting IP as a reusable corporate asset by leveraging an integrated product innovation platform to create the digital thread.

Please enjoy the summary below, or click the report or title to download the full PDF (free of charge, no registration required) sponsored by Dassault Systemes.

Also see the Consumer Goods Technology webcast New Approaches to Improve Product Development (free of charge, no registration required), also sponsored by Dassault Systemes.

The The CPG Digital Thread ebook shares how consumer packaged goods (CPG) companies can streamline their product innovation and commercialization practices by innovating along the digital thread. It shares how companies can simultaneously enable R&D to innovate more efficiently while capturing the resulting IP as a reusable corporate asset by leveraging an integrated product innovation platform to create the digital thread.

Please enjoy the summary below, or click the report or title to download the full PDF (free of charge, no registration required) sponsored by Dassault Systemes.

Also see the Consumer Goods Technology webcast New Approaches to Improve Product Development (free of charge, no registration required), also sponsored by Dassault Systemes.

Innovate Along the Digital Thread

CPG companies have the opportunity to step up their product innovation processes and productivity to compete in crowded, competitive markets. In order to do that, they can leverage the digital thread to:

- Enable individual contributors with the right tools

- Integrate design tools within a product innovation platform that serves as the digital thread backbone

- Keep resulting information in context from early ideas through production and commercialization

- Make product information readily searchable to leverage product IP company wide

- Enable easier, more social collaboration

- Automate and streamline product documentation

Of course this can’t be done with today’s disconnected tools, data, and office productivity tools like documents, presentations, and spreadsheets. As PLM for CPG, Personal Care, and Cosmetics advises, “Understand that spreadsheets and shared folders are not enough to fuel the speed and throughput requirements to remain competitive in formula-based industries.” Science Lifecycle Management in the Enterprise Ecosystem goes further, explaining that “Disjointed solutions and lack of integration leads to inefficiency, inability to reuse lab results, difficulty running analytics to find trends, and no mechanism to leverage scientific knowledge to become a ‘learning organization’ that leverages its scientific know-how.”

Of course this can’t be done with today’s disconnected tools, data, and office productivity tools like documents, presentations, and spreadsheets. As PLM for CPG, Personal Care, and Cosmetics advises, “Understand that spreadsheets and shared folders are not enough to fuel the speed and throughput requirements to remain competitive in formula-based industries.” Science Lifecycle Management in the Enterprise Ecosystem goes further, explaining that “Disjointed solutions and lack of integration leads to inefficiency, inability to reuse lab results, difficulty running analytics to find trends, and no mechanism to leverage scientific knowledge to become a ‘learning organization’ that leverages its scientific know-how.”

Instead, the digital thread removes the burden from innovators while creating a manageable IP asset that provides value well into the future, resulting in better corporate IP, more time for innovators to innovate, fewer recalls, faster time-to-market, higher productivity, and happy consumers. The time for the digital thread to transform product innovation and delight consumers has arrived. Consumer Packaged Goods Companies that don’t move toward a digital thread enabled by a product innovation platform will be at a disadvantage.

[post_title] => The CPG Digital Thread [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => cpg-digital-thread [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:27:46 [post_modified_gmt] => 2022-11-15 03:27:46 [post_content_filtered] => [post_parent] => 0 [guid] => http://tech-clarity.com/?p=4961 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 1 [filter] => raw ) [11] => WP_Post Object ( [ID] => 4956 [post_author] => 2 [post_date] => 2016-01-04 18:16:42 [post_date_gmt] => 2016-01-04 23:16:42 [post_content] => Jim Brown offers some advice on selecting PLM systems in this TechTarget article Choosing a PLM System for Your Company? Start with Strategy. The report includes a requirements framework you can use to select the right vendor partner.

This is part three of a four part series. Prior article What can PLM technology dor for Enterprises? explores the benefits of PLM and PLM tools can cure and prevent product development ailments describes who can benefit from Product Lifecycle Management.

Jim Brown offers some advice on selecting PLM systems in this TechTarget article Choosing a PLM System for Your Company? Start with Strategy. The report includes a requirements framework you can use to select the right vendor partner.

This is part three of a four part series. Prior article What can PLM technology dor for Enterprises? explores the benefits of PLM and PLM tools can cure and prevent product development ailments describes who can benefit from Product Lifecycle Management.

[post_title] => Choosing a PLM System? Start with Strategy!

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => tech-target-3

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:53

[post_modified_gmt] => 2022-11-15 03:25:53

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4956

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[12] => WP_Post Object

(

[ID] => 4946

[post_author] => 2

[post_date] => 2015-12-10 10:39:20

[post_date_gmt] => 2015-12-10 15:39:20

[post_content] => Jim Brown contributed a guest post to the Dassault Systèmes blog sharing some research on PLM for midsize manufacturing companies. The post explains how these smaller companies sometimes feel stuck between the need for a full featured PLM system to get their engineering and product development processes under control and less capable file-sharing systems that are easier to adopt but don't provide the capabilities they need.

Read the post on the 3DS blog now.

[post_title] => Choosing a PLM System? Start with Strategy!

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => tech-target-3

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:53

[post_modified_gmt] => 2022-11-15 03:25:53

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4956

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[12] => WP_Post Object

(

[ID] => 4946

[post_author] => 2

[post_date] => 2015-12-10 10:39:20

[post_date_gmt] => 2015-12-10 15:39:20

[post_content] => Jim Brown contributed a guest post to the Dassault Systèmes blog sharing some research on PLM for midsize manufacturing companies. The post explains how these smaller companies sometimes feel stuck between the need for a full featured PLM system to get their engineering and product development processes under control and less capable file-sharing systems that are easier to adopt but don't provide the capabilities they need.

Read the post on the 3DS blog now.

[post_title] => Solving the PLM Impasse for Midsize Manufacturers - Guest Post on Dassault Systemes

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => plm-smb

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:59

[post_modified_gmt] => 2022-11-15 03:25:59

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4946

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[13] => WP_Post Object

(

[ID] => 4941

[post_author] => 2

[post_date] => 2015-12-08 13:19:01

[post_date_gmt] => 2015-12-08 18:19:01

[post_content] =>

[post_title] => Solving the PLM Impasse for Midsize Manufacturers - Guest Post on Dassault Systemes

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => plm-smb

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:59

[post_modified_gmt] => 2022-11-15 03:25:59

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4946

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[13] => WP_Post Object

(

[ID] => 4941

[post_author] => 2

[post_date] => 2015-12-08 13:19:01

[post_date_gmt] => 2015-12-08 18:19:01

[post_content] =>  Jim Brown shares the value and benefits of PLM in this TechTarget article PLM tools can cure and prevent product development ailments, answering the question "who can benefit from Product Lifecycle Management?" in part two of this four part series.

Jim Brown shares the value and benefits of PLM in this TechTarget article PLM tools can cure and prevent product development ailments, answering the question "who can benefit from Product Lifecycle Management?" in part two of this four part series.

[post_title] => PLM Cures and Prevents Product Development Ailments - TechTarget Article

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => plm-techtarget-2

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:52

[post_modified_gmt] => 2022-11-15 03:25:52

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4941

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[14] => WP_Post Object

(

[ID] => 4930

[post_author] => 2

[post_date] => 2015-12-02 13:39:51

[post_date_gmt] => 2015-12-02 18:39:51

[post_content] =>

[post_title] => PLM Cures and Prevents Product Development Ailments - TechTarget Article

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => plm-techtarget-2

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:52

[post_modified_gmt] => 2022-11-15 03:25:52

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4941

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[14] => WP_Post Object

(

[ID] => 4930

[post_author] => 2

[post_date] => 2015-12-02 13:39:51

[post_date_gmt] => 2015-12-02 18:39:51

[post_content] =>  Jim Brown contributes his views on PLM and how it helps manufacturers in this TechTarget article What can PLM technology dor for Enterprises.

Jim Brown contributes his views on PLM and how it helps manufacturers in this TechTarget article What can PLM technology dor for Enterprises.

[post_title] => What PLM can do for Enterprises - TechTarget Article

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => plm-techtarget-1

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:52

[post_modified_gmt] => 2022-11-15 03:25:52

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4930

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[15] => WP_Post Object

(

[ID] => 4920

[post_author] => 2

[post_date] => 2015-11-20 11:15:19

[post_date_gmt] => 2015-11-20 16:15:19

[post_content] => Jim Brown and Dassault Systémes' VP Kendall Pond will present on this Engineering.com webcast sharing insights on the value of PLM for aerospace and automative suppliers that have outgrown their informal data management approaches. Companies in the auto and aero supply chains can learn how to better manage data, processes, and collaboration with Product Lifecycle Management, and how it can help them create a digital continuity from concept to through retirement.

[post_title] => What PLM can do for Enterprises - TechTarget Article

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => plm-techtarget-1

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:52

[post_modified_gmt] => 2022-11-15 03:25:52

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4930

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[15] => WP_Post Object

(

[ID] => 4920

[post_author] => 2

[post_date] => 2015-11-20 11:15:19

[post_date_gmt] => 2015-11-20 16:15:19

[post_content] => Jim Brown and Dassault Systémes' VP Kendall Pond will present on this Engineering.com webcast sharing insights on the value of PLM for aerospace and automative suppliers that have outgrown their informal data management approaches. Companies in the auto and aero supply chains can learn how to better manage data, processes, and collaboration with Product Lifecycle Management, and how it can help them create a digital continuity from concept to through retirement.

Listen to the recorded webcast now. Free of charge, registration required. Sponsored by Dassault Systemes

Listen to the recorded webcast now. Free of charge, registration required. Sponsored by Dassault Systemes

[post_title] => Webinar on PLM For Auto and Aero Suppliers

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => webinar-aero-auto-plm

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:43

[post_modified_gmt] => 2022-11-15 03:26:43

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4920

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[16] => WP_Post Object

(

[ID] => 4912

[post_author] => 2

[post_date] => 2015-11-17 10:20:33

[post_date_gmt] => 2015-11-17 15:20:33

[post_content] => How do you tell true cloud PLM software versus other SaaS options and why is it important? We start this episode by poking some fun at old software disguised as cloud. Then, Jim Brown interviews Excellims Corporation's VP of Engineering Mark Osgood who shares his experience outgrowing spreadsheets for managing product lifecycles, finding PLM systems cost prohibitive, and then implementing a "cloud" PLM solution that wasn't truly cloud, with poor results. Then hes implemented a native cloud PLM solution. The differences in performance is dramatic.

[post_title] => Webinar on PLM For Auto and Aero Suppliers

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => webinar-aero-auto-plm

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:43

[post_modified_gmt] => 2022-11-15 03:26:43

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4920

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[16] => WP_Post Object

(

[ID] => 4912

[post_author] => 2

[post_date] => 2015-11-17 10:20:33

[post_date_gmt] => 2015-11-17 15:20:33

[post_content] => How do you tell true cloud PLM software versus other SaaS options and why is it important? We start this episode by poking some fun at old software disguised as cloud. Then, Jim Brown interviews Excellims Corporation's VP of Engineering Mark Osgood who shares his experience outgrowing spreadsheets for managing product lifecycles, finding PLM systems cost prohibitive, and then implementing a "cloud" PLM solution that wasn't truly cloud, with poor results. Then hes implemented a native cloud PLM solution. The differences in performance is dramatic.

The video series is brought to you by Autodesk PLM360.

PLM411 brings you straight talk about how manufacturers can accelerate product innovation and product development with PLM.

For more visit PLM411.com or the Tech-Clarity YouTube Channel.

https://youtu.be/BrdTuJ5Gl-c

The video series is brought to you by Autodesk PLM360.

PLM411 brings you straight talk about how manufacturers can accelerate product innovation and product development with PLM.

For more visit PLM411.com or the Tech-Clarity YouTube Channel.

https://youtu.be/BrdTuJ5Gl-c

Prior Episode:We take a silly look at solving the problem of fragmented product data and processes with a mythical integration product called FlōSēl. Then we get down to business with Tech-Clarity's Jim Brown and CIMdata's Stan Przybylinski discussing the reasons people customize their PLM systems, the potential downfalls of doing it, and the changing customization / configuration scenario given recent software architecture changes like web services and the Cloud.

Prior Episode:We take a silly look at solving the problem of fragmented product data and processes with a mythical integration product called FlōSēl. Then we get down to business with Tech-Clarity's Jim Brown and CIMdata's Stan Przybylinski discussing the reasons people customize their PLM systems, the potential downfalls of doing it, and the changing customization / configuration scenario given recent software architecture changes like web services and the Cloud.

Next Episode: The next video shares some of the funnier moments from our 2015 infomercials and then tackles a serious question, “Should startups use PLM?,” in an interview with Autodesk’s Laurent Rains and Tech-Clarity’s Jim Brown.

[post_title] => SaaS-O-Matic Spoof and Interview on True Cloud PLM with Excellims

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => plm411-11

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:29:56

[post_modified_gmt] => 2022-11-15 03:29:56

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4912

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 1

[filter] => raw

)

[17] => WP_Post Object

(

[ID] => 4904

[post_author] => 2572

[post_date] => 2015-10-27 13:15:13

[post_date_gmt] => 2015-10-27 17:15:13

[post_content] => Michelle Boucher joins Engineering.com and Boris Marovic of Mentor Graphics as they discuss how tools like CFD, sliding meshes and parametric studies can help engineers simulate products such as pumps and turbochargers.

Listen to the recording (free of charge, registration required).

The webinar is October 27, 2015 at 2:00 EDT.

Next Episode: The next video shares some of the funnier moments from our 2015 infomercials and then tackles a serious question, “Should startups use PLM?,” in an interview with Autodesk’s Laurent Rains and Tech-Clarity’s Jim Brown.

[post_title] => SaaS-O-Matic Spoof and Interview on True Cloud PLM with Excellims

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => plm411-11

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:29:56

[post_modified_gmt] => 2022-11-15 03:29:56

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4912

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 1

[filter] => raw

)

[17] => WP_Post Object

(

[ID] => 4904

[post_author] => 2572

[post_date] => 2015-10-27 13:15:13

[post_date_gmt] => 2015-10-27 17:15:13

[post_content] => Michelle Boucher joins Engineering.com and Boris Marovic of Mentor Graphics as they discuss how tools like CFD, sliding meshes and parametric studies can help engineers simulate products such as pumps and turbochargers.

Listen to the recording (free of charge, registration required).

The webinar is October 27, 2015 at 2:00 EDT.

[post_title] => CFD Webcast

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cfd-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:43

[post_modified_gmt] => 2022-11-15 03:26:43

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4904

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[18] => WP_Post Object

(

[ID] => 4896

[post_author] => 2

[post_date] => 2015-10-26 13:46:52

[post_date_gmt] => 2015-10-26 17:46:52

[post_content] => Jim Brown penned a post on evergreen design for PTC's Product Lifecycle Report Blog. The report, IoT Makes "As Good as the Day I Bought It" a Thing of the Past, shares the exciting potential available from smart, connected products that can be updated in the field to correct issues, improve performance, or add new capabilities.

Read the post on the PTC Blog (free of charge, no registration required)

[post_title] => CFD Webcast

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cfd-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:43

[post_modified_gmt] => 2022-11-15 03:26:43

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4904

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[18] => WP_Post Object

(

[ID] => 4896

[post_author] => 2

[post_date] => 2015-10-26 13:46:52

[post_date_gmt] => 2015-10-26 17:46:52

[post_content] => Jim Brown penned a post on evergreen design for PTC's Product Lifecycle Report Blog. The report, IoT Makes "As Good as the Day I Bought It" a Thing of the Past, shares the exciting potential available from smart, connected products that can be updated in the field to correct issues, improve performance, or add new capabilities.

Read the post on the PTC Blog (free of charge, no registration required)

[post_title] => IoT Makes As Good as the Day I Bought It a Thing of the Past Guest Post on PTC's Product Lifecycle Report

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => iot-evergreen

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:59

[post_modified_gmt] => 2022-11-15 03:25:59

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4896

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[19] => WP_Post Object

(

[ID] => 4879

[post_author] => 2

[post_date] => 2015-10-20 12:02:04

[post_date_gmt] => 2015-10-20 16:02:04

[post_content] => Jim Brown shared his views on the value of location independence in this guest post titled Can’t beam me the part? Ok, how about just the 3D printing instructions? on the GrabCAD blog.

[post_title] => IoT Makes As Good as the Day I Bought It a Thing of the Past Guest Post on PTC's Product Lifecycle Report

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => iot-evergreen

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:59

[post_modified_gmt] => 2022-11-15 03:25:59

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4896

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[19] => WP_Post Object

(

[ID] => 4879

[post_author] => 2

[post_date] => 2015-10-20 12:02:04

[post_date_gmt] => 2015-10-20 16:02:04

[post_content] => Jim Brown shared his views on the value of location independence in this guest post titled Can’t beam me the part? Ok, how about just the 3D printing instructions? on the GrabCAD blog.

[post_title] => 3D Printing Drives Manufacturing Location Independence (Guest Post on GrabCAD Blog)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => 3d-printing-location

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:59

[post_modified_gmt] => 2022-11-15 03:25:59

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4879

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

)

[post_count] => 20

[current_post] => -1

[before_loop] => 1

[in_the_loop] =>

[post] => WP_Post Object

(

[ID] => 5067

[post_author] => 2572

[post_date] => 2016-03-01 11:22:49

[post_date_gmt] => 2016-03-01 16:22:49

[post_content] => The concept phase is critical for innovation. Tech-Clarity's Improving Concept Design to Boost Revenue infographic steps through what companies attempt to achieve during the concept phase, how the most successful companies approach concept development, and the benefits they enjoy as a result.

Additional information can be found in our related research report, Improving Concept Design: Innovating at the Front End to Drive Revenue Opportunities.

For for more information on concept design, please visit our sponsor, Siemens PLM.

[post_title] => 3D Printing Drives Manufacturing Location Independence (Guest Post on GrabCAD Blog)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => 3d-printing-location

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:59

[post_modified_gmt] => 2022-11-15 03:25:59

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4879

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

)

[post_count] => 20

[current_post] => -1

[before_loop] => 1

[in_the_loop] =>

[post] => WP_Post Object

(

[ID] => 5067

[post_author] => 2572

[post_date] => 2016-03-01 11:22:49

[post_date_gmt] => 2016-03-01 16:22:49

[post_content] => The concept phase is critical for innovation. Tech-Clarity's Improving Concept Design to Boost Revenue infographic steps through what companies attempt to achieve during the concept phase, how the most successful companies approach concept development, and the benefits they enjoy as a result.

Additional information can be found in our related research report, Improving Concept Design: Innovating at the Front End to Drive Revenue Opportunities.

For for more information on concept design, please visit our sponsor, Siemens PLM.

[post_title] => Infographic: Improving Concept Design to Boost Revenue

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => infographic-concept-design

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:51

[post_modified_gmt] => 2022-11-15 03:27:51

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5067

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[comment_count] => 0

[current_comment] => -1

[found_posts] => 876

[max_num_pages] => 44

[max_num_comment_pages] => 0

[is_single] =>

[is_preview] =>

[is_page] =>

[is_archive] =>

[is_date] =>

[is_year] =>

[is_month] =>

[is_day] =>

[is_time] =>

[is_author] =>

[is_category] =>

[is_tag] =>

[is_tax] =>

[is_search] =>

[is_feed] =>

[is_comment_feed] =>

[is_trackback] =>

[is_home] => 1

[is_privacy_policy] =>

[is_404] =>

[is_embed] =>

[is_paged] =>

[is_admin] =>

[is_attachment] =>

[is_singular] =>

[is_robots] =>

[is_favicon] =>

[is_posts_page] =>

[is_post_type_archive] =>

[query_vars_hash:WP_Query:private] => cfaa564aed0402f27173b0e2fedc7ffb

[query_vars_changed:WP_Query:private] => 1

[thumbnails_cached] =>

[allow_query_attachment_by_filename:protected] =>

[stopwords:WP_Query:private] =>

[compat_fields:WP_Query:private] => Array

(

[0] => query_vars_hash

[1] => query_vars_changed

)

[compat_methods:WP_Query:private] => Array

(

[0] => init_query_flags

[1] => parse_tax_query

)

[query_cache_key:WP_Query:private] => wp_query:c7c895cd80bd5f6630018fbcb7f66d7b:0.23856700 17690401040.24756200 1769040104

)

[post_title] => Infographic: Improving Concept Design to Boost Revenue

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => infographic-concept-design

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:51

[post_modified_gmt] => 2022-11-15 03:27:51

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5067

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[comment_count] => 0

[current_comment] => -1

[found_posts] => 876

[max_num_pages] => 44

[max_num_comment_pages] => 0

[is_single] =>

[is_preview] =>

[is_page] =>

[is_archive] =>

[is_date] =>

[is_year] =>

[is_month] =>

[is_day] =>

[is_time] =>

[is_author] =>

[is_category] =>

[is_tag] =>

[is_tax] =>

[is_search] =>

[is_feed] =>

[is_comment_feed] =>

[is_trackback] =>

[is_home] => 1

[is_privacy_policy] =>

[is_404] =>

[is_embed] =>

[is_paged] =>

[is_admin] =>

[is_attachment] =>

[is_singular] =>

[is_robots] =>

[is_favicon] =>

[is_posts_page] =>

[is_post_type_archive] =>

[query_vars_hash:WP_Query:private] => cfaa564aed0402f27173b0e2fedc7ffb

[query_vars_changed:WP_Query:private] => 1

[thumbnails_cached] =>

[allow_query_attachment_by_filename:protected] =>

[stopwords:WP_Query:private] =>

[compat_fields:WP_Query:private] => Array

(

[0] => query_vars_hash

[1] => query_vars_changed

)

[compat_methods:WP_Query:private] => Array

(

[0] => init_query_flags

[1] => parse_tax_query

)

[query_cache_key:WP_Query:private] => wp_query:c7c895cd80bd5f6630018fbcb7f66d7b:0.23856700 17690401040.24756200 1769040104

)

All Results for "All"

Preparing Industrial Equipment Manufacturers for Growth

Preparing Industrial Equipment Manufacturers for Growth: Innovating Future Product Lines with Higher Margins identifies how industrial equipment manufacturers can transform their business to a position of growth by implementing a strategy for innovation, without investing in additional resources. With the right approach to innovation, companies will ensure future revenue streams, while managing risk. Getting this right is…

What’s the Strategic Payback from PDM? (animation)

This short Tech-Clarity TV animation explains the strategic, financial value of PDM. Most companies get plenty of cost savings that justify the investment in PDM, but should also recognize the strategic, top-line benefits that PDM delivers. This episode is sponsored by Siemens PLM. Learn more about Siemens PLM and their Teamcenter Rapid Start Program or see…

PLM411 PLM Flexibility and Supporting Corporate Strategy Interview with Suretank

In this episode of PLM411, Tech-Clarity’s Jim Brown discusses the PLM evolution at Suretank with Barry Woods, Systems Project Manager. Barry shares that Suretank had very traditional goals for PLM, primarily revision management and getting data under control. That was a success, but new management arrived and shifted company focus to World Class Customer Care….

Improving Concept Design

Improving Concept Design: Innovating at the Front End to Drive Revenue Opportunities examines the importance of the concept phase. The report reveals survey results highlighting not only what companies can do to improve the concept phase, but also how to take advantage of concept work during later stages of product development. Please enjoy the summary below, or click the report or…

Improving Profitability for Configured Products

Improving Profitability for Configured Products: Leveraging Sales Configuration and Design Automation explores how companies can profitability tailor products to meet customer needs. The research investigates the experiences of several companies, revealing several key areas companies should focus on to improve their profitability. Please enjoy the summary below, or click the report to download a PDF overview (free…

Selecting the Right PLM Partner

Jim Brown offers some advice on selecting PLM systems in this TechTarget article A PLM Systems Comparison of the Industry’s Top Tools. The report also shares some insights on the leading PLM vendors. This is the final article of a four part series. Prior article What can PLM technology dor for Enterprises? explores the benefits of PLM and PLM tools…

PLM411 Infomercial Recap / Interview on Whether Startups Should use PLM

This video shares some of the funnier moments from our 2015 infomercials and then tackles a serious question, “Should startups use PLM?,” in an interview with Autodesk’s Laurent Rains and Tech-Clarity’s Jim Brown. The video series is brought to you by Autodesk PLM360. PLM411 brings you straight talk about how manufacturers can accelerate product innovation and product…

Webcast Driving a Competitive Edge Through Customization

Jim Brown joins Mark Rogers of Price HVAC and Rick Smith of Siemens PLM to discuss how to improve ETO processes and performance. Jim will share findings from a recent survey on what strategies, best practices, and enabling technologies top performing manufacturers use to gain higher profits from their customized products. Register now (free of charge, registration required)…

Are You Changing CAD Tools?

Are You Changing CAD Tools? What You Should Know shares survey results exploring the motivating factors behind changing CAD tools as well what companies can expect when making a change. The research examines the experiences of companies who have gone through a CAD change. It reveals key metrics such as the how much legacy data companies convert, how long to resume full productivity, and…

The CPG Digital Thread

The The CPG Digital Thread ebook shares how consumer packaged goods (CPG) companies can streamline their product innovation and commercialization practices by innovating along the digital thread. It shares how companies can simultaneously enable R&D to innovate more efficiently while capturing the resulting IP as a reusable corporate asset by leveraging an integrated product innovation platform to create the digital…

Choosing a PLM System? Start with Strategy!

Jim Brown offers some advice on selecting PLM systems in this TechTarget article Choosing a PLM System for Your Company? Start with Strategy. The report includes a requirements framework you can use to select the right vendor partner. This is part three of a four part series. Prior article What can PLM technology dor for Enterprises? explores the…

Solving the PLM Impasse for Midsize Manufacturers – Guest Post on Dassault Systemes

Jim Brown contributed a guest post to the Dassault Systèmes blog sharing some research on PLM for midsize manufacturing companies. The post explains how these smaller companies sometimes feel stuck between the need for a full featured PLM system to get their engineering and product development processes under control and less capable file-sharing systems that…

PLM Cures and Prevents Product Development Ailments – TechTarget Article

Jim Brown shares the value and benefits of PLM in this TechTarget article PLM tools can cure and prevent product development ailments, answering the question “who can benefit from Product Lifecycle Management?” in part two of this four part series.

What PLM can do for Enterprises – TechTarget Article

Jim Brown contributes his views on PLM and how it helps manufacturers in this TechTarget article What can PLM technology dor for Enterprises.

Webinar on PLM For Auto and Aero Suppliers

Jim Brown and Dassault Systémes‘ VP Kendall Pond will present on this Engineering.com webcast sharing insights on the value of PLM for aerospace and automative suppliers that have outgrown their informal data management approaches. Companies in the auto and aero supply chains can learn how to better manage data, processes, and collaboration with Product Lifecycle…

SaaS-O-Matic Spoof and Interview on True Cloud PLM with Excellims

How do you tell true cloud PLM software versus other SaaS options and why is it important? We start this episode by poking some fun at old software disguised as cloud. Then, Jim Brown interviews Excellims Corporation’s VP of Engineering Mark Osgood who shares his experience outgrowing spreadsheets for managing product lifecycles, finding PLM systems cost…

CFD Webcast

Michelle Boucher joins Engineering.com and Boris Marovic of Mentor Graphics as they discuss how tools like CFD, sliding meshes and parametric studies can help engineers simulate products such as pumps and turbochargers. Listen to the recording (free of charge, registration required). The webinar is October 27, 2015 at 2:00 EDT.

IoT Makes As Good as the Day I Bought It a Thing of the Past Guest Post on PTC’s Product Lifecycle Report

Jim Brown penned a post on evergreen design for PTC’s Product Lifecycle Report Blog. The report, IoT Makes “As Good as the Day I Bought It” a Thing of the Past, shares the exciting potential available from smart, connected products that can be updated in the field to correct issues, improve performance, or add new capabilities….

3D Printing Drives Manufacturing Location Independence (Guest Post on GrabCAD Blog)

Jim Brown shared his views on the value of location independence in this guest post titled Can’t beam me the part? Ok, how about just the 3D printing instructions? on the GrabCAD blog.