This episode of Tech-Clarity TV focuses on how Aerospace & Defense (A&D) companies can save costs by consolidating on a single CAD platform. The episode shares findings from our Containing CAD Costs in A&D – How CAD Consolidation Leads to Cost Reduction and Strategic Differentiation report. The video shares specific examples of how a consolidated CAD platform has helped other A&D…

- If you already completed the survey --> please share with a colleague using the "Share/Save" options above.

- If you haven't taken the survey --> please:

click here to take the survey now!

The video series is brought to you by Autodesk PLM360.

PLM411 brings you straight talk about how manufacturers can accelerate product innovation and product development with PLM.

For more visit PLM411.com or the Tech-Clarity YouTube Channel.

http://youtu.be/REx9Krk-OO8

The video series is brought to you by Autodesk PLM360.

PLM411 brings you straight talk about how manufacturers can accelerate product innovation and product development with PLM.

For more visit PLM411.com or the Tech-Clarity YouTube Channel.

http://youtu.be/REx9Krk-OO8

Prior Episode: Funny Big Software Spoof informercial and a discussion with Oyo Sportstoys COO Martin Hanssmann on how PLM helps Oyo with time to market, managing complexity, and quality.

Next Episode: A silly story about how one product developer convinced his company to improve product development with PLM, along with a candid discussion between host Jim Brown of Tech-Clarity and Brian Roepke of Autodesk about the benefits of cloud-based solutions and why Autodesk chose to bring a cloud PLM solution to market.

[post_title] => PLM411 SāmPāg Collaboration Software Parody / ECO and PLM Interview

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => plm411-04

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:29:51

[post_modified_gmt] => 2022-11-15 03:29:51

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4184

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[5] => WP_Post Object

(

[ID] => 4179

[post_author] => 2

[post_date] => 2014-12-03 14:25:35

[post_date_gmt] => 2014-12-03 19:25:35

[post_content] =>

Prior Episode: Funny Big Software Spoof informercial and a discussion with Oyo Sportstoys COO Martin Hanssmann on how PLM helps Oyo with time to market, managing complexity, and quality.

Next Episode: A silly story about how one product developer convinced his company to improve product development with PLM, along with a candid discussion between host Jim Brown of Tech-Clarity and Brian Roepke of Autodesk about the benefits of cloud-based solutions and why Autodesk chose to bring a cloud PLM solution to market.

[post_title] => PLM411 SāmPāg Collaboration Software Parody / ECO and PLM Interview

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => plm411-04

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:29:51

[post_modified_gmt] => 2022-11-15 03:29:51

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4184

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[5] => WP_Post Object

(

[ID] => 4179

[post_author] => 2

[post_date] => 2014-12-03 14:25:35

[post_date_gmt] => 2014-12-03 19:25:35

[post_content] =>  Tell us how satisfied you are with your PDM / PLM system!

Tell us how satisfied you are with your PDM / PLM system!

- This survey is now closed. We are in the process of determining the winners of the incentives.

In addition, 200 respondents will receive a $10 Amazon gift card. See rules and eligibility requirements below.

The survey should take no more than 10 minutes to complete.

In addition, 200 respondents will receive a $10 Amazon gift card. See rules and eligibility requirements below.

The survey should take no more than 10 minutes to complete.

More Information

Tech-Clarity is conducting a research study to determine the level of satisfaction users have with their PLM/PDM systems. Individual responses will be used in aggregate form only. We may publish comments and share information from those that explicitly agree that we may do so.Rules

To be eligible for this offer, you must be a professional with job responsibilities related to or supporting the development, release, or manufacture of products. Vendors and consultants who sell software, solutions, or services to support product development are not eligible. Students without professional work experience are also not eligible. A valid work email is required to receive the gift card. To verify eligibility, your work email must include the domain of your place of employment. Email addresses will be kept confidential and will not be used for any direct sales or marketing purposes unless you specifically opt in. Duplicate responses will be disqualified. Winners will be notified when the survey is closed.

[post_title] => PLM User Satisfaction Survey [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => plm-sat-survey [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:27:43 [post_modified_gmt] => 2022-11-15 03:27:43 [post_content_filtered] => [post_parent] => 0 [guid] => http://tech-clarity.com/?p=4179 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 2 [filter] => raw ) [6] => WP_Post Object ( [ID] => 4147 [post_author] => 2572 [post_date] => 2014-12-03 13:14:02 [post_date_gmt] => 2014-12-03 18:14:02 [post_content] => Tech-Clarity Insight: Containing CAD Costs in A&D - How CAD Consolidation Leads to Cost Reduction and Strategic Differentiation explores how aerospace and defense companies can save money by consolidating CAD solutions. The report examines key criteria in a CAD solution that are needed to support design best practices for A&D companies.

Please enjoy the summary below, or click the report to download a PDF overview (free of charge, no registration required).

For the full report, please visit our sponsor Siemens at their Aerospace & Defense page.

Watch the related episode of Tech-Clarity TV, Consolidating CAD for A&D.

Tech-Clarity Insight: Containing CAD Costs in A&D - How CAD Consolidation Leads to Cost Reduction and Strategic Differentiation explores how aerospace and defense companies can save money by consolidating CAD solutions. The report examines key criteria in a CAD solution that are needed to support design best practices for A&D companies.

Please enjoy the summary below, or click the report to download a PDF overview (free of charge, no registration required).

For the full report, please visit our sponsor Siemens at their Aerospace & Defense page.

Watch the related episode of Tech-Clarity TV, Consolidating CAD for A&D.

Table of Contents

- Executive Overview

- Considerations for A&D

- Consider CAD Consolidation to Reduce Cost

- Low Cost of Solution Ownership

- Improve Collaboration with Suppliers/Customers

- Increase Reuse

- Support Lightweight Aircraft Design

- Capture a System Level View

- Identify Problems Early

- Extend Access to Engineering Information Beyond Engineering

- Conclusion

- Recommendations

- About the Author

Executive Overview

The Aerospace and Defense (A&D) industry faces significant pressure to manage costs. In an industry fraught with cost overruns and missed deadlines, those who are most successful removing cost enjoy competitive differentiation and greater profitability. One strategy to remove cost from the development process is to consolidate Computer Aided Design (CAD) applications. Past research from Tech-Clarity shows there are significant cost savings from CAD consolidation. This report builds upon that research with a focus on A&D. While cost may be the initial reason for considering CAD consolidation, the benefits go far beyond cost. As Tech-Clarity’s Consolidating CAD – The Benefits of a Unified CAD Strategy points out, “Cost savings are attractive and are certainly attainable through consolidation. Beyond cost savings, though, are even greater strategic benefits.” With this in mind, it is important to ensure the unified CAD solution supports best practices in A&D design. This will have the twofold impact of driving innovation as well as saving costs. Part of these savings comes from the ability to take advantage of proven, repeatable processes. It’s easier for the entire team to be following the same repeatable process when using consistent tools. Repeatable processes mean greater efficiency plus less risk that will drive up costs. Selecting the right tool is an important part of making sure those processes and best practices are supported. The right tool is one that has the breadth of solution to support those design practices to not only support today’s needs, but also the ability to carry A&D companies decades into the future. [post_title] => Containing CAD Costs in A&D [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => cad-costs-ad [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:27:41 [post_modified_gmt] => 2022-11-15 03:27:41 [post_content_filtered] => [post_parent] => 0 [guid] => http://tech-clarity.com/?p=4147 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [7] => WP_Post Object ( [ID] => 4133 [post_author] => 2572 [post_date] => 2014-11-13 19:20:18 [post_date_gmt] => 2014-11-14 00:20:18 [post_content] => Tech- Clarity Perspective: Reducing Non-Value Added Work in Engineering - Improving Efficiency with Real-Time Access to Design Information shares survey results from nearly 250 manufacturers identifying areas that hurt engineering efficiency and distract from developing better products. The study examines the practices of the “Top Performers,” those that are more profitable, to determine best practices to streamline access to design information.

Please enjoy the summary below, or click the report or title to download the full PDF (free of charge, no registration required, courtesy of Dassault Systemes).

For more information on accessing design data in real-time, please visit the Dassault Systemes Enovia Page.

Clarity Perspective: Reducing Non-Value Added Work in Engineering - Improving Efficiency with Real-Time Access to Design Information shares survey results from nearly 250 manufacturers identifying areas that hurt engineering efficiency and distract from developing better products. The study examines the practices of the “Top Performers,” those that are more profitable, to determine best practices to streamline access to design information.

Please enjoy the summary below, or click the report or title to download the full PDF (free of charge, no registration required, courtesy of Dassault Systemes).

For more information on accessing design data in real-time, please visit the Dassault Systemes Enovia Page.

Table of Contents

- Executive Overview

- Empower Engineers to Innovate

- Identify Bottlenecks and Contributors to Non-Value Added Work

- Recognize the Time Required for Check-ins

- Understand the Impact of Outdated Information on Changes

- Consider the Impact of Outdated Information on Collaboration

- Identifying the Top Performers

- What Sets Top Performers Apart?

- Use Technology to Support Real-Time Communication

- Consider the Security Risks of Email

- Support Real-time CAD Updates

- Conclusion

- Recommendations

- About the Author

- About the Research

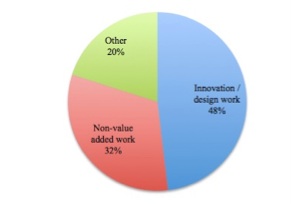

Executive Overview

To be successful in today’s market, companies need to keep engineers focused on developing differentiated products that stand out from the competition. Engineers can create this differentiation by developing products that offer higher quality, better performance, and greater innovation at a reasonable price. Unfortunately, engineers report that rather than focusing on this important work, on average, they spend a third of their time on non-value added work. Even worse, 20% of their time is spent working with outdated information, which often leads to wasted effort and rework. Providing engineers with real time access to design data, in the right context, is one way to improve efficiency and streamline engineering decisions. To determine best practices for accessing design information, Tech-Clarity analyzed survey responses from nearly 250 manufacturers to understand how they manage data, communicate engineering changes, and collaborate with both internal and external members of the development team. The analysis separated respondents into two performance bands based on their ability to hit targets for five product development-related metrics. The “Top Performers” were identified as those who are better than their competitors at quickly and efficiently designing high quality, innovative products that meet cost targets. Then, researchers analyzed what Top Performers are doing differently compared to “Others.” This report explores best practices for streamlining access to real time design data. It also exposes some challenges manufacturers should be aware of as they strive to maintain a competitive edge in today’s complex and cutthroat environment. With this information, manufacturers can plan for a design environment that will prepare them for long-term competitiveness.The research shows that compared to competitors, Top Performers are nearly 2-times more likely to maintain up-to-date models. The fact that they get real-time updates is supported by PDM/PLM. [post_title] => Reducing Non-Value Added Work in Engineering [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => reduce-nva-work [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:27:41 [post_modified_gmt] => 2022-11-15 03:27:41 [post_content_filtered] => [post_parent] => 0 [guid] => http://tech-clarity.com/?p=4133 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 4 [filter] => raw ) [8] => WP_Post Object ( [ID] => 4118 [post_author] => 2 [post_date] => 2014-11-06 17:03:21 [post_date_gmt] => 2014-11-06 22:03:21 [post_content] => Issue in Focus: Mastering the Development of Smart Products - Raising Process and Systems Maturity to Improve Quality and Time-to-Market discusses the impacts that developing "smart" products has on product design and development. The report shares best practices for developing these products and managing the complexity arising from the integration of mechanical, electrical, and software design elements into the final product.

Please enjoy the summary below, or click the report or title to download the full PDF (free of charge, no registration required).

For more information from our sponsor please visit the Dassault Systèmes High-Tech Resources Center.

Issue in Focus: Mastering the Development of Smart Products - Raising Process and Systems Maturity to Improve Quality and Time-to-Market discusses the impacts that developing "smart" products has on product design and development. The report shares best practices for developing these products and managing the complexity arising from the integration of mechanical, electrical, and software design elements into the final product.

Please enjoy the summary below, or click the report or title to download the full PDF (free of charge, no registration required).

For more information from our sponsor please visit the Dassault Systèmes High-Tech Resources Center.

Table of Contents

- Introducing the Issue

- Improve Mechatronic Product Development Maturity

- Define the Target

- Plan the Product

- Validate Early and Often

- Design by Discipline and Validate to Interfaces

- Aggressively Manage Change

- Enable an Integrated Lifecycle View

- Conclusion

- Recommendations

- About the Author

Introducing the Issue

Products are getting smarter. Today’s “smart” products leverage an intelligent combination of mechanical, electrical, and software to deliver capabilities that simply weren’t achievable with traditional approaches. Products are more responsive, adaptable, interconnected, and portable than ever. The trend is significant. As Tech-Clarity’s Developing Software-Intensive Products indicates, manufacturers have not only increased the amount of software in products over the last five years, but “the importance of software in products and the level of product innovation driven by software have also increased significantly.” Smart products are compelling to consumers. It’s hard to compete with a car that drives and parks itself or a clothes washer that senses and adjusts to water conditions, fabric types, and dirt levels. Likewise, a medical device that monitors its performance and schedules service when it needs repair offers significantly higher customer value. Benefits will increase even further as smart products become more aware and communicative, such as mobile phones that interact with neighboring devices, appliances, automobiles, and more. It’s clear why consumers like smart products, but there are even more reasons for manufacturers to love them. As Tech-Clarity’s Systems & Software Driven Innovation concludes, “Leading companies will look to take advantage of (mechatronics) to improve their ability to tailor products, increase reuse, make agile updates to products in the field, reduce product cost, and lower product development cost.” Smart products are the new reality. What impact do they have on engineering and product development? [post_title] => Mastering the Development of Smart Products [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => smart-products [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:27:40 [post_modified_gmt] => 2022-11-15 03:27:40 [post_content_filtered] => [post_parent] => 0 [guid] => http://tech-clarity.com/?p=4118 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [9] => WP_Post Object ( [ID] => 4110 [post_author] => 2 [post_date] => 2014-11-04 15:28:18 [post_date_gmt] => 2014-11-04 20:28:18 [post_content] => Watch some funny videos about PLM and then stay for some insights and education on how PLM can help manufacturers accelerate and improve product development. Our first three videos make fun of the scourge of Change Management Paralysis, introduce the "innovative" Recipe Manager 2020, and rip on Big Software. All of these carry an important message about the issues manufacturers face, but more importantly offer each a bit of a lighthearted break from the monotony of the work day. They also share interviews with a leading industry analyst, a PLM software executive, and a company very effectively using PLM. The episodes dig into Who Should Use PLM, How PLM Helps, and a success story at Oyo Sportstoys. Share with a friend or colleague! Share on social media! Episode 1: Change Management Syndrome (CMS) Informercial and a chat with Allan Behrens of Taxal about which companies should consider PLM. Episode 2: Recipe Manager 2020 Informercial and a great discussion with Autodesk’s Ron Locklin on how PLM helps manufacturers improve product development and innovation.

Episode 2: Recipe Manager 2020 Informercial and a great discussion with Autodesk’s Ron Locklin on how PLM helps manufacturers improve product development and innovation.

Episode 3: Funny Big Software Spoof informercial and a discussion with Oyo Sportstoys COO Martin Hanssmann on how PLM helps Oyo with time to market, managing complexity, and quality.

Episode 3: Funny Big Software Spoof informercial and a discussion with Oyo Sportstoys COO Martin Hanssmann on how PLM helps Oyo with time to market, managing complexity, and quality.

[post_title] => Having Fun with PLM411 (recapping first three videos)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => plm411-1to3

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:29:51

[post_modified_gmt] => 2022-11-15 03:29:51

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4110

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 4

[filter] => raw

)

[10] => WP_Post Object

(

[ID] => 4097

[post_author] => 2

[post_date] => 2014-10-21 11:37:37

[post_date_gmt] => 2014-10-21 15:37:37

[post_content] => PLM411 shares a funny view on the impacts of "Big Software" implementations. After the infomercial, Jim Brown of Tech-Clarity discusses the PLM implementation at Oyo Sportstoys with Oyo Sports COO Martin Hanssmann.

Our goal with PLM411 is to bring you straight talk about how manufacturers use PLM to accelerate product innovation and product development.

[post_title] => Having Fun with PLM411 (recapping first three videos)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => plm411-1to3

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:29:51

[post_modified_gmt] => 2022-11-15 03:29:51

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4110

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 4

[filter] => raw

)

[10] => WP_Post Object

(

[ID] => 4097

[post_author] => 2

[post_date] => 2014-10-21 11:37:37

[post_date_gmt] => 2014-10-21 15:37:37

[post_content] => PLM411 shares a funny view on the impacts of "Big Software" implementations. After the infomercial, Jim Brown of Tech-Clarity discusses the PLM implementation at Oyo Sportstoys with Oyo Sports COO Martin Hanssmann.

Our goal with PLM411 is to bring you straight talk about how manufacturers use PLM to accelerate product innovation and product development.

The video series is brought to you by Autodesk PLM360.

PLM411 brings you straight talk about how manufacturers can accelerate product innovation and product development with PLM.

For more visit PLM411.com or the Tech-Clarity YouTube Channel.

http://youtu.be/ju5zJBTrvl0

The video series is brought to you by Autodesk PLM360.

PLM411 brings you straight talk about how manufacturers can accelerate product innovation and product development with PLM.

For more visit PLM411.com or the Tech-Clarity YouTube Channel.

http://youtu.be/ju5zJBTrvl0

Prior Episode: Recipe Manager 2020 Informercial and a great discussion with Autodesk’s Ron Locklin on how PLM helps manufacturers improve product development and innovation.

Next Episode: A jab at collaboration software getting you on the "same page" followed by a discussion with Chad Jackson of Lifecycle Insights on Engineering Change Management and how PLM software can help.

[post_title] => PLM411 Big Software Spoof / PLM Success at Oyo Sportstoys

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => plm411-03

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:29:50

[post_modified_gmt] => 2022-11-15 03:29:50

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4097

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[11] => WP_Post Object

(

[ID] => 4084

[post_author] => 2

[post_date] => 2014-10-20 07:00:18

[post_date_gmt] => 2014-10-20 11:00:18

[post_content] =>

Prior Episode: Recipe Manager 2020 Informercial and a great discussion with Autodesk’s Ron Locklin on how PLM helps manufacturers improve product development and innovation.

Next Episode: A jab at collaboration software getting you on the "same page" followed by a discussion with Chad Jackson of Lifecycle Insights on Engineering Change Management and how PLM software can help.

[post_title] => PLM411 Big Software Spoof / PLM Success at Oyo Sportstoys

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => plm411-03

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:29:50

[post_modified_gmt] => 2022-11-15 03:29:50

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4097

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[11] => WP_Post Object

(

[ID] => 4084

[post_author] => 2

[post_date] => 2014-10-20 07:00:18

[post_date_gmt] => 2014-10-20 11:00:18

[post_content] =>  Design Data Management Survey

Design Data Management Survey

This survey is now closed. We are in the process of notifying the recipients of the gift cards. Thank you for your support. Please feel free to read the resulting report, The Facts about Managing Product Data.

Please share your views on how manufacturers manage their engineering and design data.

- If you already completed the survey –> please share with a colleague or on social media using the “Share/Save” options above.

- If you haven’t taken the survey –> please:

CLICK HERE TO TAKE THE SURVEY NOW!

In addition, 200 respondents will receive a $10 Amazon gift card. See rules and eligibility requirements below.

The survey should take no more than 10 minutes to complete. Individual responses will be kept confidential.

In addition, 200 respondents will receive a $10 Amazon gift card. See rules and eligibility requirements below.

The survey should take no more than 10 minutes to complete. Individual responses will be kept confidential.

Rules

To be eligible for this offer, you must be a professional with job responsibilities related to or supporting the development, release, or manufacture of products. Vendors and consultants who sell software, solutions, or services to support product development are not eligible. Students without professional work experience are also not eligible. A valid work email is required to receive the gift card. To verify eligibility, your work email must include the domain of your place of employment. Email addresses will be kept confidential and will not be used for any direct sales or marketing purposes. Duplicate responses will be disqualified. Winners will be notified when the survey is closed.

[post_title] => Design Data Management Survey [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => ddm-survey [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:27:40 [post_modified_gmt] => 2022-11-15 03:27:40 [post_content_filtered] => [post_parent] => 0 [guid] => http://tech-clarity.com/?p=4084 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 7 [filter] => raw ) [12] => WP_Post Object ( [ID] => 4052 [post_author] => 2 [post_date] => 2014-10-02 14:14:35 [post_date_gmt] => 2014-10-02 18:14:35 [post_content] => PLM411 takes a funny look at how manufacturers manage their Bills of Material in the Recipe Manager 2020 spoof, followed by some straight talk on how PLM helps manufacturers improve business performance. Tech-Clarity President Jim Brown and Ron Locklin of Autodesk discuss the ways PLM helps companies give insight into their products and save them money . The video series is brought to you by Autodesk PLM360.

PLM411 brings you straight talk about how manufacturers can accelerate product innovation and product development with PLM.

For more visit PLM411.com or the Tech-Clarity YouTube Channel.

http://youtu.be/sT2HeENCW7k

The video series is brought to you by Autodesk PLM360.

PLM411 brings you straight talk about how manufacturers can accelerate product innovation and product development with PLM.

For more visit PLM411.com or the Tech-Clarity YouTube Channel.

http://youtu.be/sT2HeENCW7k

Previous Episode:

Previous Episode:  Change Management Syndrome (CMS) Informercial and a chat with Allan Behrens of Taxal about which companies should consider PLM.

Next Episode: Funny Big Software Spoof informercial and a discussion with Oyo Sportstoys COO Martin Hanssmann on how PLM helps Oyo with time to market, managing complexity, and quality.

[post_title] => PLM411 Recipe Manager Informercial / How Can PLM Help my Business?

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => plm411-02

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:29:50

[post_modified_gmt] => 2022-11-15 03:29:50

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4052

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[13] => WP_Post Object

(

[ID] => 4007

[post_author] => 2

[post_date] => 2014-09-16 08:39:30

[post_date_gmt] => 2014-09-16 12:39:30

[post_content] => Tech-Clarity announces a new video series with the release of the first PLM411 episode, "Is PLM Right for my Business?" The video starts with a funny infomercial on the scurge of "change management paralysis" in manufacturing, and then transitions to a frank discussion between Jim Brown of Tech-Clarity and Allan Behrens of Taxal on which companies can improve and accelerate product innovation and product development with PLM.

Change Management Syndrome (CMS) Informercial and a chat with Allan Behrens of Taxal about which companies should consider PLM.

Next Episode: Funny Big Software Spoof informercial and a discussion with Oyo Sportstoys COO Martin Hanssmann on how PLM helps Oyo with time to market, managing complexity, and quality.

[post_title] => PLM411 Recipe Manager Informercial / How Can PLM Help my Business?

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => plm411-02

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:29:50

[post_modified_gmt] => 2022-11-15 03:29:50

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4052

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[13] => WP_Post Object

(

[ID] => 4007

[post_author] => 2

[post_date] => 2014-09-16 08:39:30

[post_date_gmt] => 2014-09-16 12:39:30

[post_content] => Tech-Clarity announces a new video series with the release of the first PLM411 episode, "Is PLM Right for my Business?" The video starts with a funny infomercial on the scurge of "change management paralysis" in manufacturing, and then transitions to a frank discussion between Jim Brown of Tech-Clarity and Allan Behrens of Taxal on which companies can improve and accelerate product innovation and product development with PLM.

The video series is brought to you by Autodesk PLM360.

PLM411 brings you straight talk about how manufacturers can accelerate product innovation and product development with PLM.

For more visit PLM411.com or the Tech-Clarity YouTube Channel.

http://youtu.be/x0iCmznAEAA

The video series is brought to you by Autodesk PLM360.

PLM411 brings you straight talk about how manufacturers can accelerate product innovation and product development with PLM.

For more visit PLM411.com or the Tech-Clarity YouTube Channel.

http://youtu.be/x0iCmznAEAA

Next Episode: Recipe Manager 2020 Informercial and a great discussion with Autodesk's Ron Locklin on how PLM helps manufacturers improve their product innovation and development.

[post_title] => PLM411 Change Management Syndrome Infomercial / Is PLM Right for my Business?

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => plm411-01

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:29:50

[post_modified_gmt] => 2022-11-15 03:29:50

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4007

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 1

[filter] => raw

)

[14] => WP_Post Object

(

[ID] => 3996

[post_author] => 2

[post_date] => 2014-09-02 09:18:52

[post_date_gmt] => 2014-09-02 13:18:52

[post_content] => This episode of Tech-Clarity TV explores how manufacturers like GM and Boeing partner with academic institutions, government agencies, and software vendors to increase the job readiness of STEM graduates. The episode shares findings from our Developing the STEM Workforce of the Future: Partnering to Meet the Demand for Engineering and Manufacturing Talent paper. A key finding is that these partnerships can fill a common gap in most STEM academic programs - practical experience - through engaging, real-world experience.

http://youtu.be/SJYMNkunw34

Watch this and more educational videos on the Tech-Clarity YouTube channel.

[post_title] => Tech-Clarity TV - Partnering to Develop the STEM Workforce of the Future

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => stem-tctv

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:29:49

[post_modified_gmt] => 2022-11-15 03:29:49

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=3996

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[15] => WP_Post Object

(

[ID] => 3989

[post_author] => 2

[post_date] => 2014-09-02 09:14:52

[post_date_gmt] => 2014-09-02 13:14:52

[post_content] => [caption id="attachment_3992" align="alignright" width="232"]

Next Episode: Recipe Manager 2020 Informercial and a great discussion with Autodesk's Ron Locklin on how PLM helps manufacturers improve their product innovation and development.

[post_title] => PLM411 Change Management Syndrome Infomercial / Is PLM Right for my Business?

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => plm411-01

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:29:50

[post_modified_gmt] => 2022-11-15 03:29:50

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4007

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 1

[filter] => raw

)

[14] => WP_Post Object

(

[ID] => 3996

[post_author] => 2

[post_date] => 2014-09-02 09:18:52

[post_date_gmt] => 2014-09-02 13:18:52

[post_content] => This episode of Tech-Clarity TV explores how manufacturers like GM and Boeing partner with academic institutions, government agencies, and software vendors to increase the job readiness of STEM graduates. The episode shares findings from our Developing the STEM Workforce of the Future: Partnering to Meet the Demand for Engineering and Manufacturing Talent paper. A key finding is that these partnerships can fill a common gap in most STEM academic programs - practical experience - through engaging, real-world experience.

http://youtu.be/SJYMNkunw34

Watch this and more educational videos on the Tech-Clarity YouTube channel.

[post_title] => Tech-Clarity TV - Partnering to Develop the STEM Workforce of the Future

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => stem-tctv

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:29:49

[post_modified_gmt] => 2022-11-15 03:29:49

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=3996

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[15] => WP_Post Object

(

[ID] => 3989

[post_author] => 2

[post_date] => 2014-09-02 09:14:52

[post_date_gmt] => 2014-09-02 13:14:52

[post_content] => [caption id="attachment_3992" align="alignright" width="232"] Developing the STEM Workforce Paper PDF on Tech-Clarity Site[/caption]

Developing the STEM Workforce of the Future: Partnering to Meet the Demand for Engineering and Manufacturing Talent discusses the shortcomings of the current education system in producing a sufficient number of qualified candidates to fill engineering and manufacturing jobs. The study doesn't focus on the gap, but instead identifies some of the causes and explores how manufacturers are developing more qualified candidates by partnering with academics, government, and software vendors. The key finding from the research is that these partnerships are successfully augmenting the current, theoretically-oriented educational approach with hands-on experience.

Please enjoy the summary below, or click the report or title to download the full PDF (free of charge, no registration required, courtesy of Siemens PLM).

Watch the related episode of Tech-Clarity TV, Partnering to Develop the STEM Workforce of the Future.

Developing the STEM Workforce Paper PDF on Tech-Clarity Site[/caption]

Developing the STEM Workforce of the Future: Partnering to Meet the Demand for Engineering and Manufacturing Talent discusses the shortcomings of the current education system in producing a sufficient number of qualified candidates to fill engineering and manufacturing jobs. The study doesn't focus on the gap, but instead identifies some of the causes and explores how manufacturers are developing more qualified candidates by partnering with academics, government, and software vendors. The key finding from the research is that these partnerships are successfully augmenting the current, theoretically-oriented educational approach with hands-on experience.

Please enjoy the summary below, or click the report or title to download the full PDF (free of charge, no registration required, courtesy of Siemens PLM).

Watch the related episode of Tech-Clarity TV, Partnering to Develop the STEM Workforce of the Future.

Table of Contents

- Executive Overview

- Understand The Implications of the Technical Workforce Gap

- Recognize Industry’s Needs and Perspective

- Evaluate Current Academic Programs

- Evolve Academic Programs

- Governments’ Role

- Recognize the Growing Role of Software Providers

- Partner to Develop the Workforce of the Future

- Listen to the Student’s Perspective

- Learn from Success Stories – Greenpower

- Learn from Success Stories - EcoCAR

- Learn from Success Stories - Others

- Conclusion

- Recommendations

- About the Author

Executive Overview

Not too long ago the term “STEM” didn’t mean much to most of us. In recent years, however, numerous studies show that much of the world faces an engineering and manufacturing workforce shortage. This casts a lot of attention on science, technology, engineering, and mathematics (STEM) education. There are a variety of causes for the technical skills gap, including:- Increased demand due to the manufacturing renaissance, recovering economies, and “re-shoring” manufacturing closer to demand driving greater need for technically qualified employees

- A large number of skilled, experience employees reaching retirement age

- Practical, engaging experiences

- Real, industrial-strength processes and tools

- Involved mentors

- Committed leadership and funding

Tech-Clarity Insight - Creating the Environment to Innovate, How Industry Leaders Put People, Processes, and Technology in Place to Drive Innovation shares our insights and the perspective of three leading companies on how to best create an atmosphere that fosters innovation. The report explains that companies must put a realistic improvement plan in place that covers people, process, and technology if they want to improve innovation performance.

Please enjoy the summary below, or click the report to download a PDF overview (free of charge, no registration required).

For the full report, please visit our sponsor Planview (free of charge, registration required).

You can also view a replay of a related, 30 minute Three Elements Missing From Your Innovation Process webcast presented by Planview (free, registration required).

Tech-Clarity Insight - Creating the Environment to Innovate, How Industry Leaders Put People, Processes, and Technology in Place to Drive Innovation shares our insights and the perspective of three leading companies on how to best create an atmosphere that fosters innovation. The report explains that companies must put a realistic improvement plan in place that covers people, process, and technology if they want to improve innovation performance.

Please enjoy the summary below, or click the report to download a PDF overview (free of charge, no registration required).

For the full report, please visit our sponsor Planview (free of charge, registration required).

You can also view a replay of a related, 30 minute Three Elements Missing From Your Innovation Process webcast presented by Planview (free, registration required).

Table of Contents

- Executive Overview

- Examining People, Processes, and Technology

- Establish a Culture for Innovation

- Design Right-Sized Processes for Innovation

- Enable Innovation with Lightweight, Flexible Technology

- Adopt a Continuous Improvement Approach

- Conclusion

- Recommendations

- About the Author

Executive Overview

Companies want to raise the bar on innovation from incremental improvement to the kind of innovation that shows up in the annual report. Breakthrough innovation is visible to customers, the market, and investors. As Lana Kington, Director of Global R&D Innovation Management for Mead Johnson Nutrition points out, “Whenever our management speaks to investors, they consistently highlight our innovation performance because of its importance to our consumers, our business and our reputation.” Others agree, including Sindy Wilson, Director of Product Portfolio Analytics & Insights for Manheim Auction, “We are the industry leader and we drive innovation, it’s very visible and a very high priority.” Although innovation is important and gets a lot of attention, too few companies have a realistic plan in place to improve innovation performance. Companies don’t have an environment that fosters innovation and allows them to innovate and commercialize effectively to capitalize on their ideas. We spoke with several leading companies about how they create an environment that fosters innovation. As Manheim’s Wilson states, “You have to be fast to market to be relevant.” Companies need a plan to operationalize innovation to be more predictable, repeatable, and reduce risk. The plan must address three critical elements necessary to foster innovation – people, processes, and technology. Some may scoff at the simplicity of the “people, processes, technology” message. It probably gets as much lip service as innovation itself. But each element is critically important and there are some special considerations for each related to innovation. For example, some feel processes for innovation can slow them down. “People are always concerned that an innovation process is simply bureaucracy – and that it will slow them down; but that’s not the case,”explains Lana Kington of Mead Johnson. While that may be true, done right innovation processes help guide and streamline innovation execution. “We can have discipline and the flexibility to innovate.” Technology plays a special role in enabling innovation. “Inevitably software will speed up innovation, you gain back efficiencies tenfold by automating,” explains Immucor’s Erik Greenfield in Tech-Clarity’s Top 5 Misconceptions about Innovation Management Software. Technology helps support standard processes and metrics and provides transparency to consistent information. Good processes and technology also enable facts-based decision-making to move companies away from emotion and gut instinct to a more mature, sustainable approach. While processes and technology are crucial, the research also shows the importance of a strong innovation culture and that processes and technology must be lightweight and flexible to enable but not burden innovators, particularly in early innovation phases. [post_title] => Creating the Environment to Innovate [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => innovation-env [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:27:53 [post_modified_gmt] => 2022-11-15 03:27:53 [post_content_filtered] => [post_parent] => 0 [guid] => http://tech-clarity.com/?p=3980 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [17] => WP_Post Object ( [ID] => 3968 [post_author] => 2572 [post_date] => 2014-08-05 12:23:41 [post_date_gmt] => 2014-08-05 16:23:41 [post_content] => Tech-Clarity is conducting a research study on how top performing manufacturers manage their product design process. Past research from Tech-Clarity found that top performers spend 25% less time on nonproductive data management tasks. That gives engineers more time to innovate or allows managers to significantly reduce design cycle times. We are conducting a new research study to explore this further to examine the challenges that impact engineering and design efficiency. Thank you for your interest and your participation in our survey!

The first 25 people who respond will receive a $10 Amazon gift card. Remaining respondents will be entered into a drawing to receive one of 10 $25 Amazon gift cards.*

The survey should take no more than 10-15 minutes to complete, and we will be happy to share a free copy of the report with all respondents.

Tech-Clarity is conducting a research study on how top performing manufacturers manage their product design process. Past research from Tech-Clarity found that top performers spend 25% less time on nonproductive data management tasks. That gives engineers more time to innovate or allows managers to significantly reduce design cycle times. We are conducting a new research study to explore this further to examine the challenges that impact engineering and design efficiency. Thank you for your interest and your participation in our survey!

The first 25 people who respond will receive a $10 Amazon gift card. Remaining respondents will be entered into a drawing to receive one of 10 $25 Amazon gift cards.*

The survey should take no more than 10-15 minutes to complete, and we will be happy to share a free copy of the report with all respondents.

- If you already completed the survey --> please share with a colleague using the "Share/Save" options above.

- If you haven't taken the survey --> please:

click here to take the survey now!

All Results for "All"

Cloud PLM Webcast

Join Tech-Clarity’s Jim Brown on this webcast as he presents his views on PLM and how cloud offerings help to drop the barriers to entry. In addition, hear from Mike Gurican of Autodesk give an overview of PLM and PLM360 and discuss common issues that PLM improves, including BOM and Change Management. The webcast is sponsored by MasterGraphics and will air…

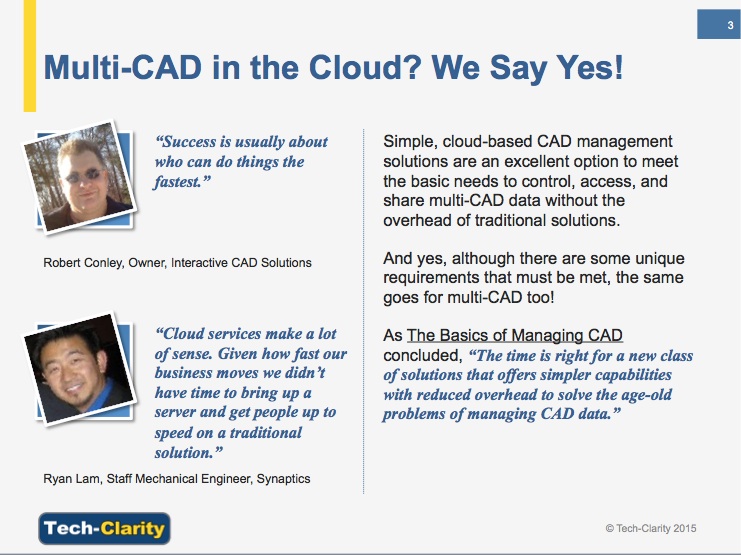

Managing Multi-CAD on a Budget

The Managing Multi-CAD Complexity on a Budget eBook discusses the challenges of managing multi-CAD data and continues the conversation started in Tech-Clarity Insight The Basics of Managing CAD about whether a simpler, lower overhead, cloud-based data management solution is enough to manage CAD files. The eBook shares the experiences of engineers from Synaptics, Interactive CAD Solutions,…

CPG Survey: Product Design Efficiency

Tech-Clarity is conducting a research study on how top performing consumer goods companies manage their product design process. Past research from Tech-Clarity found that top performers spend 25% less time on nonproductive data management tasks. That gives engineers more time to innovate or allows managers to significantly reduce design cycle times. We are conducting a research study…

PLM411 SāmPāg Collaboration Software Parody / ECO and PLM Interview

Tech-Clarity takes a jab at collaboration software with this funny infomercial on the fictitious SāmPāg solution. It highlights a real issue about how poorly companies collaborate about their products and product information. The ad is followed by a great discussion with Chad Jackson of Lifecycle Insights on Engineering Change Management and how PLM software can help….

PLM User Satisfaction Survey

Tell us how satisfied you are with your PDM / PLM system! This survey is now closed. We are in the process of determining the winners of the incentives. Please fill out this questionnaire to receive a free copy of the final report. In addition, 200 respondents will receive a $10 Amazon gift card. See…

Containing CAD Costs in A&D

Tech-Clarity Insight: Containing CAD Costs in A&D – How CAD Consolidation Leads to Cost Reduction and Strategic Differentiation explores how aerospace and defense companies can save money by consolidating CAD solutions. The report examines key criteria in a CAD solution that are needed to support design best practices for A&D companies. Please enjoy the summary below, or…

Reducing Non-Value Added Work in Engineering

Tech-Clarity Perspective: Reducing Non-Value Added Work in Engineering – Improving Efficiency with Real-Time Access to Design Information shares survey results from nearly 250 manufacturers identifying areas that hurt engineering efficiency and distract from developing better products. The study examines the practices of the “Top Performers,” those that are more profitable, to determine best practices to streamline access to design…

Mastering the Development of Smart Products

Issue in Focus: Mastering the Development of Smart Products – Raising Process and Systems Maturity to Improve Quality and Time-to-Market discusses the impacts that developing “smart” products has on product design and development. The report shares best practices for developing these products and managing the complexity arising from the integration of mechanical, electrical, and software design elements…

Having Fun with PLM411 (recapping first three videos)

Watch some funny videos about PLM and then stay for some insights and education on how PLM can help manufacturers accelerate and improve product development. Our first three videos make fun of the scourge of Change Management Paralysis, introduce the “innovative” Recipe Manager 2020, and rip on Big Software. All of these carry an important message about the…

PLM411 Big Software Spoof / PLM Success at Oyo Sportstoys

PLM411 shares a funny view on the impacts of “Big Software” implementations. After the infomercial, Jim Brown of Tech-Clarity discusses the PLM implementation at Oyo Sportstoys with Oyo Sports COO Martin Hanssmann. Our goal with PLM411 is to bring you straight talk about how manufacturers use PLM to accelerate product innovation and product development. The video…

Design Data Management Survey

Design Data Management Survey This survey is now closed. We are in the process of notifying the recipients of the gift cards. Thank you for your support. Please feel free to read the resulting report, The Facts about Managing Product Data. Please share your views on how manufacturers manage their engineering and design data. If you already completed the survey –>…

PLM411 Recipe Manager Informercial / How Can PLM Help my Business?

PLM411 takes a funny look at how manufacturers manage their Bills of Material in the Recipe Manager 2020 spoof, followed by some straight talk on how PLM helps manufacturers improve business performance. Tech-Clarity President Jim Brown and Ron Locklin of Autodesk discuss the ways PLM helps companies give insight into their products and save them money . The…

PLM411 Change Management Syndrome Infomercial / Is PLM Right for my Business?

Tech-Clarity announces a new video series with the release of the first PLM411 episode, “Is PLM Right for my Business?” The video starts with a funny infomercial on the scurge of “change management paralysis” in manufacturing, and then transitions to a frank discussion between Jim Brown of Tech-Clarity and Allan Behrens of Taxal on which companies can…

Tech-Clarity TV – Partnering to Develop the STEM Workforce of the Future

This episode of Tech-Clarity TV explores how manufacturers like GM and Boeing partner with academic institutions, government agencies, and software vendors to increase the job readiness of STEM graduates. The episode shares findings from our Developing the STEM Workforce of the Future: Partnering to Meet the Demand for Engineering and Manufacturing Talent paper. A key finding is…

Developing the STEM Workforce of the Future

Developing the STEM Workforce of the Future: Partnering to Meet the Demand for Engineering and Manufacturing Talent discusses the shortcomings of the current education system in producing a sufficient number of qualified candidates to fill engineering and manufacturing jobs. The study doesn’t focus on the gap, but instead identifies some of the causes and explores…

Creating the Environment to Innovate

Tech-Clarity Insight – Creating the Environment to Innovate, How Industry Leaders Put People, Processes, and Technology in Place to Drive Innovation shares our insights and the perspective of three leading companies on how to best create an atmosphere that fosters innovation. The report explains that companies must put a realistic improvement plan in place that…

Overcoming Product Design Bottlenecks Survey

Tech-Clarity is conducting a research study on how top performing manufacturers manage their product design process. Past research from Tech-Clarity found that top performers spend 25% less time on nonproductive data management tasks. That gives engineers more time to innovate or allows managers to significantly reduce design cycle times. We are conducting a new research…

Tech-Clarity TV – How to Buy a Design Review Solution

This Tech-Clarity TV episode shares the highlights of Tech-Clarity’s Design Review Buyer’s Guide. The video explains the importance of analyzing special considerations like scalability in addition to core product functionality. It also points out some important vendor and service requirements to ensure that the solution provides a reasonable total cost of ownership (TCO) and strong return…

Panel Discussion – Achieving Zero Files

Tech-Clarity’s Michelle Boucher joins Jeff Erno from GE, Bob Maffia from BAE, as well as Bill Ruccio and Kevin Baughan from Dassault Systèmes for an interactive panel discussion on the impact of the file on engineering. The discussion will take place at the Enovia Community Conference in Waltham, MA. The panel will explore the potential for…